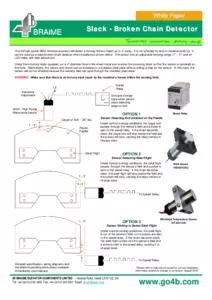

WDA3 Motion Alignment Sensor

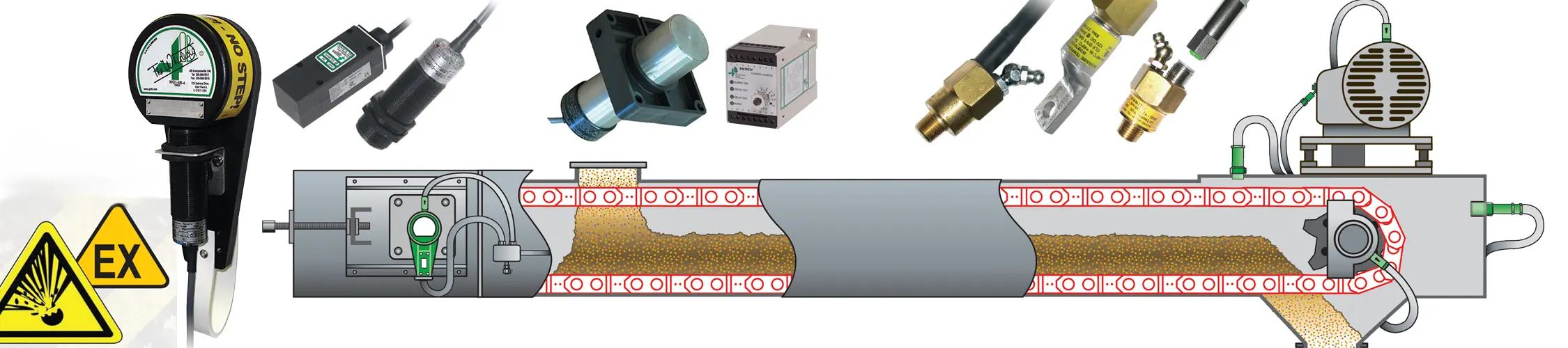

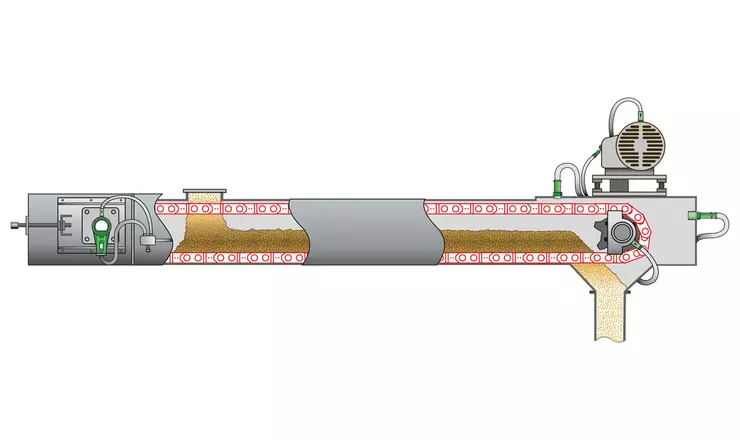

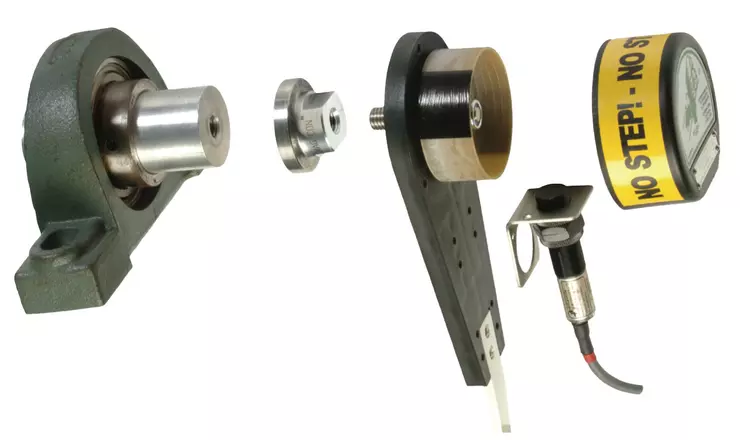

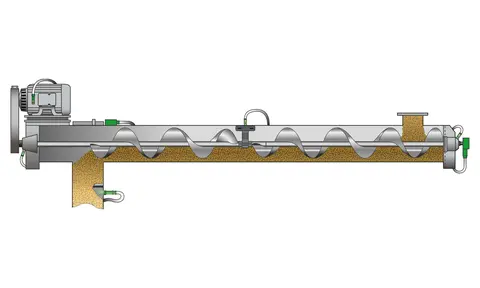

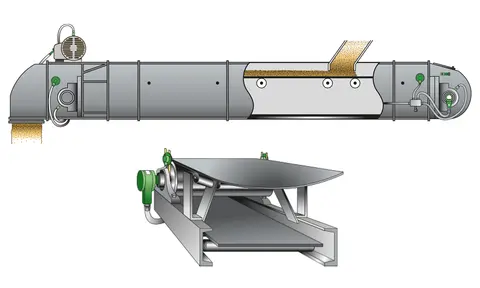

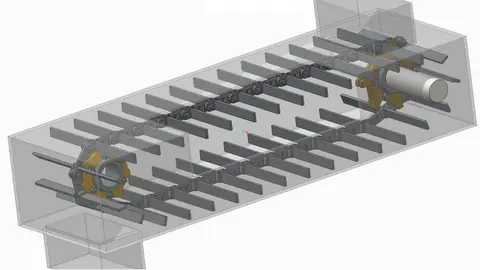

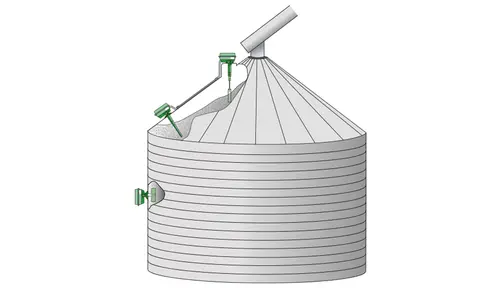

Non-contacting extended range magnetic proximity sensor, not affected by dust or material build up, used to detect moving ferrous material up to 100mm away from the sensor. The WDA sensor can be used on bucket elevators to measure speed and alignment by sensing either the metal elevator buckets, or the ferrous bolts attached to plastic buckets. A more specialized use for the WDA switch is as a broken/slack chain detector on drag chain conveyors, or as a non-contact speed switch for screw conveyors. The sensor is used in conjunction with a PLC or with 4B's Watchdog™ Elite or A400 Elite control units. Two output signals are provided: one signal is a pulse output, representing each bucket detected: the second signal is a continuous output when moving buckets are detected.