M1003 Stopswitch

Stopped Motion Monitor

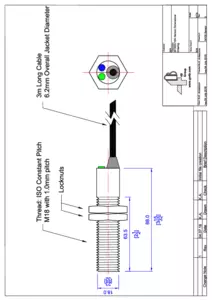

M1003V10AI

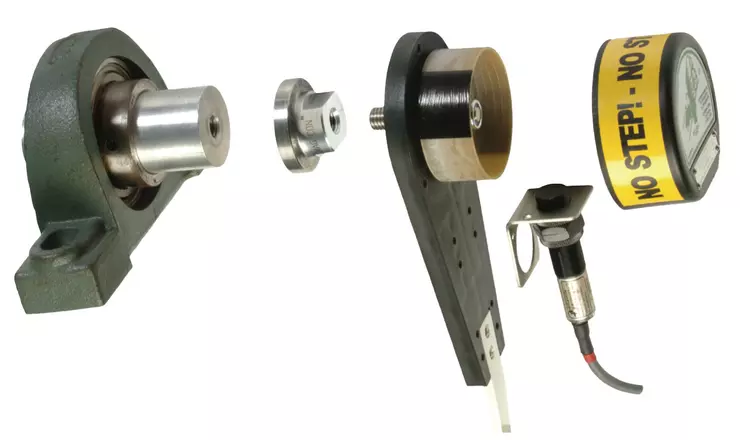

The M1003 Stopswitch is a simple inductive shaft speed monitoring device. The self-contained unit, which signals when the shaft has stopped rotating. It can be used for process control, motion detection and stopped shaft indication. An inductive sensing device located in the nose of the M100 enclosure will detect a metal target. This target can be an existing bolt head or device attached to a shaft. The M1003 Stopswitch requires no calibration and provides an output when the shaft has stopped rotating.

Product Features

- 24-240 VAC/VDC multi voltage power supply

- 2-wire

- IP66 rated

- M18 x 1.0 ISO threaded nylon body

- Green and Blue LEDs showing output state

- 6 mm detection range

- No calibration needed

- 4s start up delay

Electronics Application

Belt Conveyor

Belt Conveyor

Bucket Elevator

Bucket Elevator

Chain Conveyor

Chain Conveyor

Screw Conveyor

Screw Conveyor

Specifications

| | ||

| Specification | Value | |

| Supply Voltage: | 24 to 240 VAC/VDC | |

| Supply Fusing: | Supply to be fused at 500mA maximum | |

| Switching Capacity: | 50mA maximum | |

| Saturation Voltage: | 5.5 Volts maximum (output on) | |

| Leakage Current: | 1.0 mA maximum (output off) | |

| Ambient Temperature: | 5°F (-15°C) to +122°F (+50°C) | |

| Output State: | FET | |

| Sensing Range: | 6 mm (15/64”) maximum on ferrous metal at 77°F (25°C) | |

| Input Pulse Range: | 20 to 3,600 pulses per minute (PPM) maximum | |

| Start-Up Delay: | 4 seconds | |

| Trip Point: | zero speed | |

| Enclosure: | Nylon - ISO threaded 18 mm by 1.0 mm pitch | |

| Relative Humidity: | 90% RH | |

| LED Indicators: | Blue - Target Sensed, Green - Rotation Detected | |

| Connections: | 2 wire, 3m long cable. | |

| Protection: | IP66 |