Electronic Monitoring Equipment

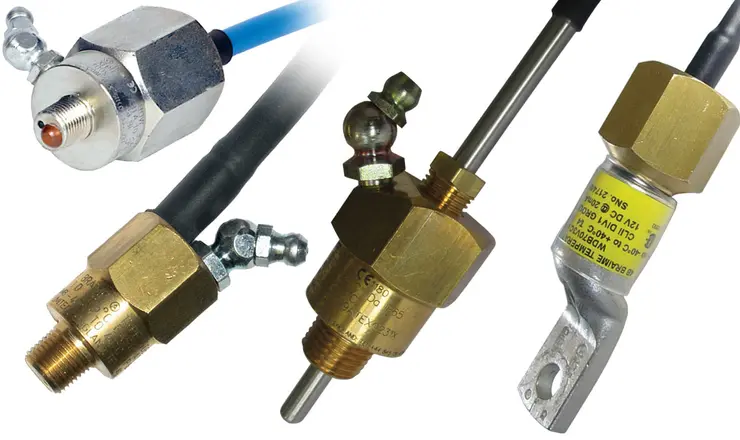

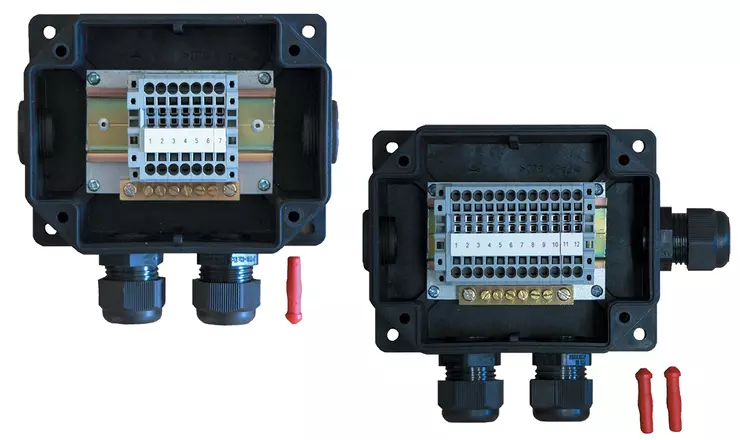

4B offers an extensive range of monitoring equipment and sensors for bucket elevators, belt and chain conveyors, screw conveyors and silos. We can offer you anything from a replacement sensor to a fully integrated hazard monitoring system which can be operated either as a stand-alone system or connected to your PLC.

Electronic Monitoring Equipment

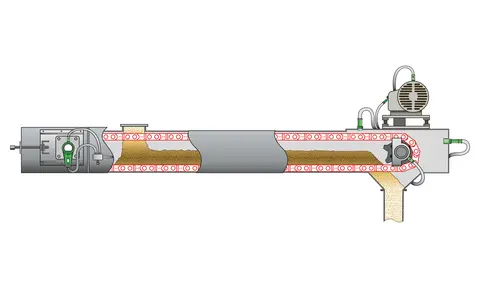

Bucket Elevator

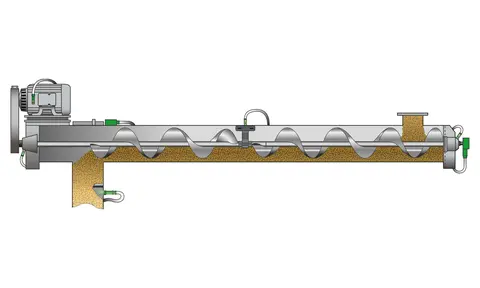

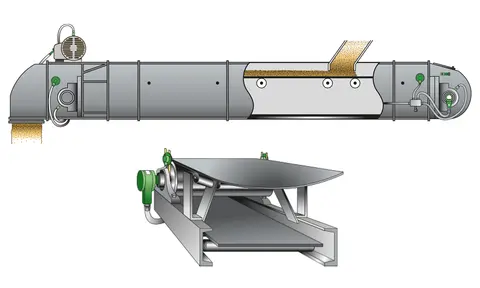

The bucket elevator is one of the most efficient methods for elevating bulk granular materials - but it is also one of the most dangerous. The dust generated from the movement of materials within the elevator can be highly explosive, and mechanical failure or incorrect operation of the bucket elevator can have catastrophic consequences. The most common hazards on bucket elevators are belt misalignment, belt slippage, blocked chutes, and bearing failures, each of which should be monitored to reduce the risk of fires, explosions or breakdowns that result in costly downtime.

4b offer a range of monitoring equipment and sensors to monitor those hazards.

(Illustration shows typical sensor placements, applications may vary).