- Provides greater capacity with fewer elevator buckets than the original Starco™ elevator bucket system

- Provides perfect fill & discharge for a wide range of products

- Operates effectively over a wide speed range

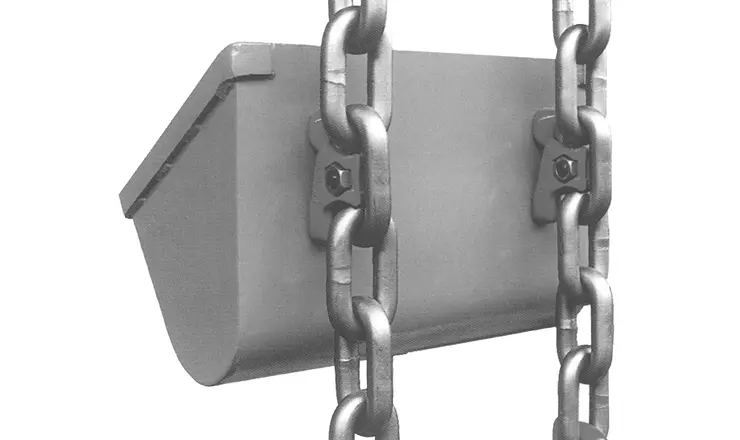

- Pressed seamless steel, no welds or joints

- Available in a large number of sizes - now up to 630-215

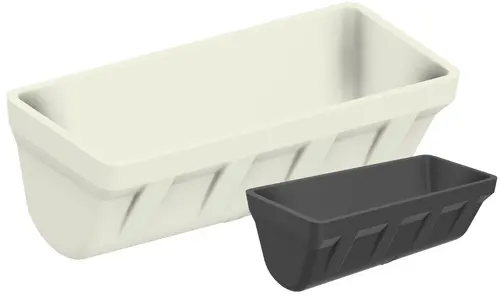

Elevator Buckets

At 4B, we have the world's largest range of elevator buckets. -With over 400 different sizes and styles, 4B is the world's leading elevator buckets manufacturer.

4B has an elevator bucket for any product and any application.

- Steel & stainless steel elevator buckets (pressed / seamless or fabricated)

- Plastic / non-metallic elevator buckets (nylon, HDP or polyurethane)

- Elevator buckets for agricultural applications (e.g. grain, feed, seeds, sugar)

- Elevator buckets for industrial applications (e.g. cement, lime, aggregates, coal, fertilizer)

Filter By:

- Provides greater capacity with fewer elevator buckets than the original Starco™ elevator bucket system

- Provides perfect fill & discharge for a wide range of products

- Operates effectively over a wide speed range

- Made from prime virgin material

- The original STARCO™ high capacity elevator bucket system

- Very popular elevator bucket, has been used in the industry over many years

- Provides perfect fill & discharge for a wide range of products

- Operates over a wide speed range, up to 4.55m/s.

- Pressed seamless steel

- The original STARCO™ high capacity elevator bucket system

- Provides perfect fill & discharge for a wide range of products

- Operates over a wide speed range, up to 4.55m/s.

- Pressed seamless steel bucket, no welds or joints

- Increased capacity

- High temperature applications

- Great strength and long life

- Clean discharge

- Can be used with steel web belt

- Double existing capacity

- Elevator buckets are closely spaced & product is elevated in an almost continuous column

- Self-cleaning - ideal for sticky materials

- Pressed seamless steel

- Stackable design for big cost savings and larger capacities

- The elevator bucket with a beam for no bowing or backlegging

- "Iceberg"™ Edge for gentler handling and longer life

- Premium virgin white poly for maximum bucket strength

- Ultra Tough and Flexible

- Thickest Front Lip, Walls and Corners for Long Life

- "Iceberg"™ Edge for gentler handling and longer life

- Stackable Design for Efficient Shipping and Storage

- Tapered Bottom for Closer Vertical Spacing (up to 4.6 buckets/metre)

- Big volume deep elevator bucket for use with free flowing materials

- For use in medium and high speed bucket elevators

- High capacity applications

- Pressed seamless steel

- Great strength and long life

- Clean discharge

- Retrofit CC style elevator buckets

- Pressed seamless steel

- Great strength and long life

- Clean discharge

- Supplied complete with standard recessed holes

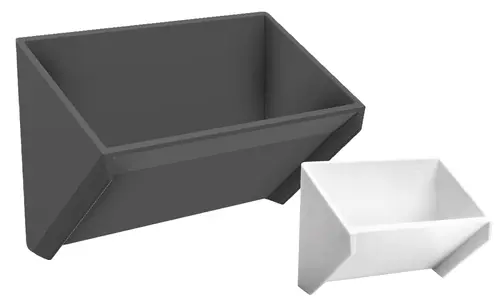

- Low front and open profile

- Ideal for handling difficult, sticky industrial materials

- Pressed seamless steel, no welds or joints

- Great strength and long life

- For sticky materials at slow speeds

- For free flowing materials at higher speed and closer spacing

- Pressed seamless steel, no welds or joints

- Elevator bucket for sticky materials at slow speeds

- For free flowing materials at higher speed and closer spacing

- Good, versatile, medium capacity elevator bucket

- Pressed seamless steel, no welds or joints

- Elevator bucket for free flowing materials only

- For other materials at slower speeds

- Pressed seamless steel, no welds or joints

- Elevator bucket for free flowing materials only

- For materials elevated at slower speeds with gravity discharge

- Heavy-duty applications

- Reinforced front lip

- Excellent wear resistance

- Excellent impact strength (Izod – 20 KJ/m2)

- Self-cleaning surfaces

- 75% lighter than fabricated steel

- Anti-Static (108 Ohms)

- Non-sparking & non-corroding

- Service Temperature: Long term -40 to +110°C (with short peaks of 150°C)

- Suitable for light to heavy abrasive industrial products, such as sand, aggregate, cement, wood chips and fertilizer.

- Solid construction: manufactured from Nylathane™ super-tough nylon

- Solid throughout: no occlusions within the structure

- Medium front for use in continuous discharge elevators

- Corrosion and abrasion resistant

- Service Temperature: Long term -40 to +110°C (with short peaks of 150°C)

- Made from Nyrim, a high grade nylon/rubber reaction moulding

- Maximum impact, corrosion and abrasion-resistant

- Suitable for industrial applications, including all aggregates

- Long bucket life

- Suitable for use with elevator belting and chain: reduced bucket weight extends chain life

- Antistatic material with excellent surface resistivity dissipating properties, ideal for ATEX applications

- Non-stick properties are enhanced by smooth surface and open bucket design

- Ultra heavy duty design and construction: material up to 6 times stronger than other industrial plastic elevator buckets

- Versatile bucket: suitable for heavy industrial, grain and sticky material applications

- Made from Nylatron cast nylon

- Heavy-duty thick walls

- Impact, corrosion and abrasion-resistant

- Anti-stick surface prevents product build-up

- Suitable for both chain and bucket or belt and bucket applications

- Available in two styles:

NBA, for use in relatively narrow elevator legs

DIN, for elevators designed around DIN NORM 15234

- Reinforced front lip

- Superior wear resistance

- Superior impact strength

- Self-cleaning surfaces

- Up to 75% lighter than fabricated steel

- Anti-Static (108 Ohms)

- Non-sparking & non-corroding