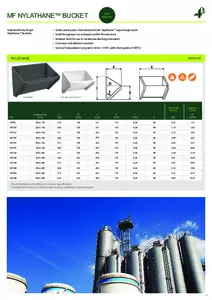

4B MF Nylathane™ Continuous Elevator Buckets

Industrial Duty Tough Nylathane™ Buckets

MF85, MF105, MF127, MF147, MF167, MF187, MF128, MF148, MF168, MF188, MF208, MF248

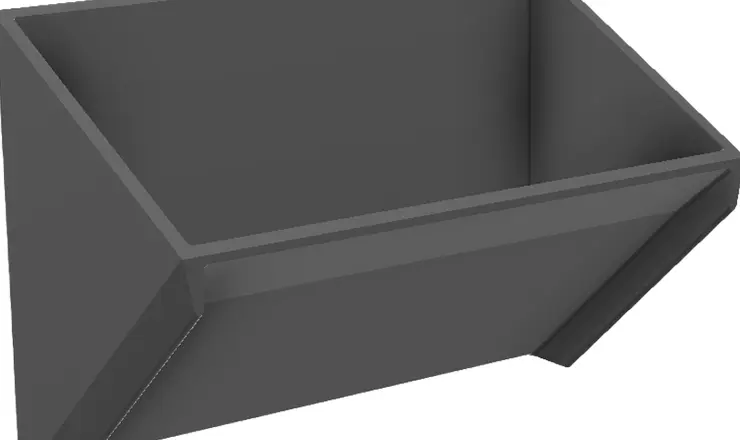

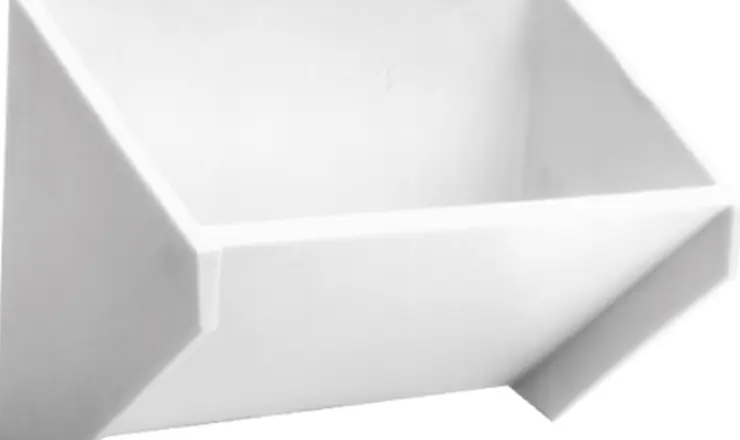

Medium front design; industrial duty tough Nylathane™ buckets.

Product Features

- Solid construction: manufactured from Nylathane™ super-tough nylon

- Solid throughout: no occlusions within the structure

- Medium front for use in continuous discharge elevators

- Corrosion and abrasion resistant

- Service Temperature: Long term -40 to +110°C (with short peaks of 150°C)

Material

Nylathane™

Use by Industry

Industrial

Use by Product

Pellets & Light Agricultural,

Light Industrial,

Heavy Industrial

Specifications

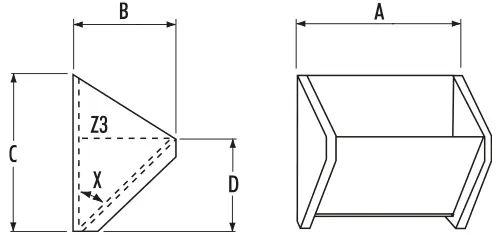

| Nominal size | A | B | C | D | T | Xº | Weight | Capacity (L) | ||

| MF Nylathane bucket | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (kg) | Z3 (water) | ||

| MF85 | 200 x 130 | 210 | 140 | 191 | 110 | 8.26 | 48 | 0.97 | 1.31 | |

| MF105 | 250 x 130 | 260 | 140 | 191 | 110 | 8.26 | 48 | 1.14 | 1.65 | |

| MF127 | 300 x 190 | 311 | 190 | 292 | 155 | 8.26 | 48 | 2.15 | 3.98 | |

| MF147 | 350 x 190 | 362 | 190 | 292 | 155 | 8.26 | 48 | 2.40 | 4.67 | |

| MF167 | 400 x 190 | 413 | 190 | 292 | 155 | 8.26 | 48 | 2.65 | 5.37 | |

| MF187 | 450 x 190 | 463 | 190 | 292 | 155 | 8.26 | 48 | 2.90 | 6.06 | |

| MF128 | 300 x 200 | 311 | 216 | 292 | 178 | 8.26 | 48 | 2.34 | 5.18 | |

| MF148 | 350 x 200 | 362 | 216 | 292 | 178 | 8.26 | 48 | 2.61 | 6.08 | |

| MF168 | 400 x 200 | 413 | 216 | 292 | 178 | 8.26 | 48 | 2.87 | 6.99 | |

| MF188 | 450 x 200 | 463 | 216 | 292 | 178 | 8.26 | 48 | 3.14 | 7.89 | |

| MF208 | 500 x 200 | 514 | 216 | 292 | 178 | 8.26 | 48 | 3.51 | 8.70 | |

| MF248 | 600 x 200 | 616 | 216 | 292 | 178 | 8.26 | 48 | 4.05 | 10.51 | |

Mounting holes and venting to customer specification

*Standard MF buckets are black; beige buckets available on special request