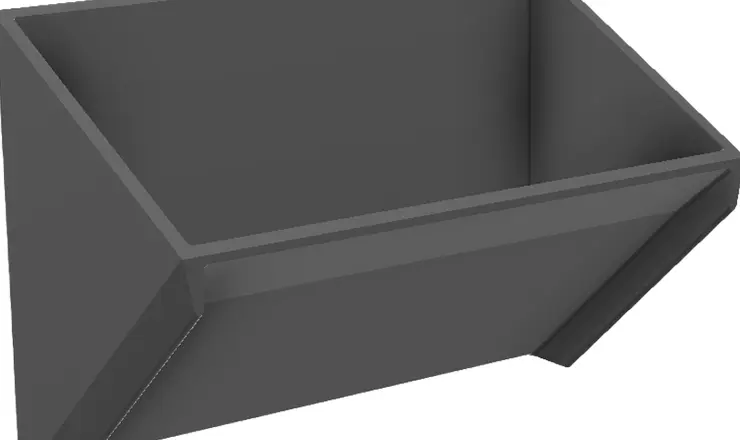

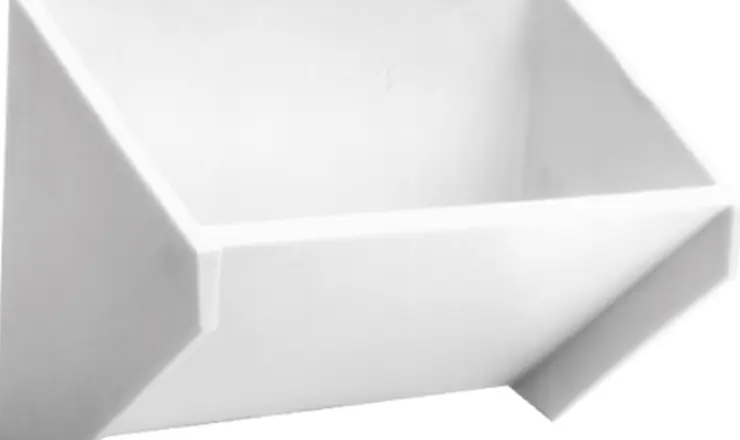

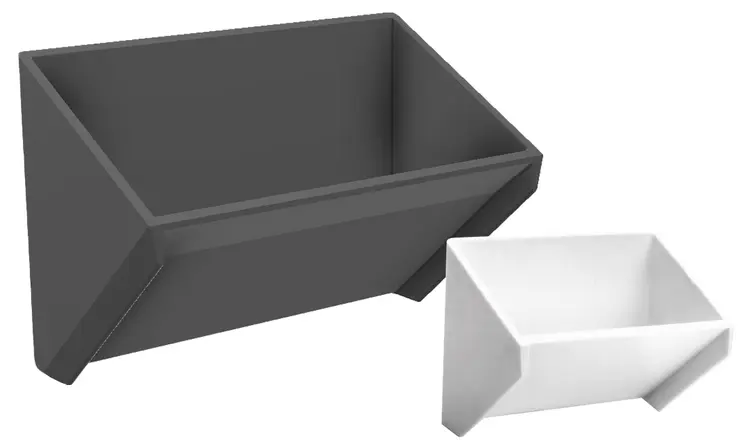

Godet 4B MF Nylathane™

Godets industriels ultrarésistants en Nylathane™

MF85, MF105, MF127, MF147, MF167, MF187, MF128, MF148, MF168, MF188, MF208, MF248

Godets d'élévateurs industriels ultrarésistants en Nylathane™

Product Features

- Construction robuste : fabriqués en Nylathane™, un nylon ultra-résistant

- Injection de haute densité

- Face avant conçue pour des déchargements en continu

- Résistant à l'abrasion et anti-colmatant

- Température d’utilisation : de -40 à +110°C (jusqu’à 150°C en pointe)

Material

Nylathane™

Use by Industry

Industrie

Use by Product

Pellets & Produits légers,

Industrie légère,

Industrie lourde

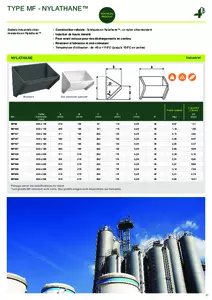

Specifications

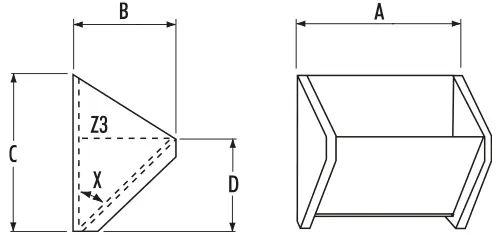

| Nominal size | A | B | C | D | T | Xº | Weight | Capacity (L) | ||

| MF Nylathane bucket | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (kg) | Z3 (water) | ||

| MF85 | 200 x 130 | 210 | 140 | 191 | 110 | 8.26 | 48 | 0.97 | 1.31 | |

| MF105 | 250 x 130 | 260 | 140 | 191 | 110 | 8.26 | 48 | 1.14 | 1.65 | |

| MF127 | 300 x 190 | 311 | 190 | 292 | 155 | 8.26 | 48 | 2.15 | 3.98 | |

| MF147 | 350 x 190 | 362 | 190 | 292 | 155 | 8.26 | 48 | 2.40 | 4.67 | |

| MF167 | 400 x 190 | 413 | 190 | 292 | 155 | 8.26 | 48 | 2.65 | 5.37 | |

| MF187 | 450 x 190 | 463 | 190 | 292 | 155 | 8.26 | 48 | 2.90 | 6.06 | |

| MF128 | 300 x 200 | 311 | 216 | 292 | 178 | 8.26 | 48 | 2.34 | 5.18 | |

| MF148 | 350 x 200 | 362 | 216 | 292 | 178 | 8.26 | 48 | 2.61 | 6.08 | |

| MF168 | 400 x 200 | 413 | 216 | 292 | 178 | 8.26 | 48 | 2.87 | 6.99 | |

| MF188 | 450 x 200 | 463 | 216 | 292 | 178 | 8.26 | 48 | 3.14 | 7.89 | |

| MF208 | 500 x 200 | 514 | 216 | 292 | 178 | 8.26 | 48 | 3.51 | 8.70 | |

| MF248 | 600 x 200 | 616 | 216 | 292 | 178 | 8.26 | 48 | 4.05 | 10.51 | |

Perçage selon les spécifications du client.

*Les godets MF standard sont noirs. Des godets beiges sont disponibles sur demande.