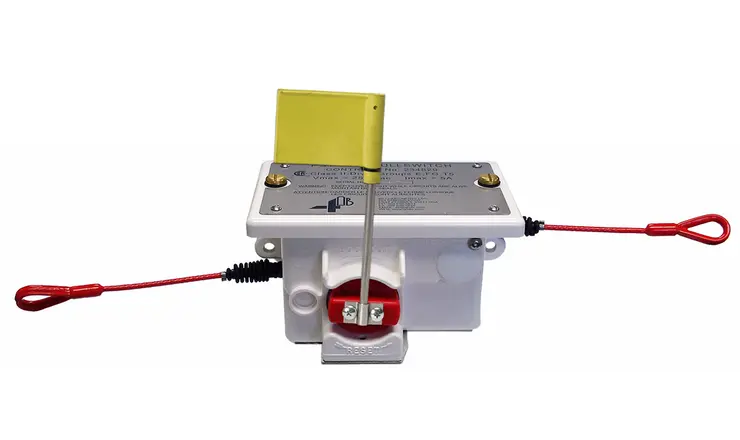

Bulldog

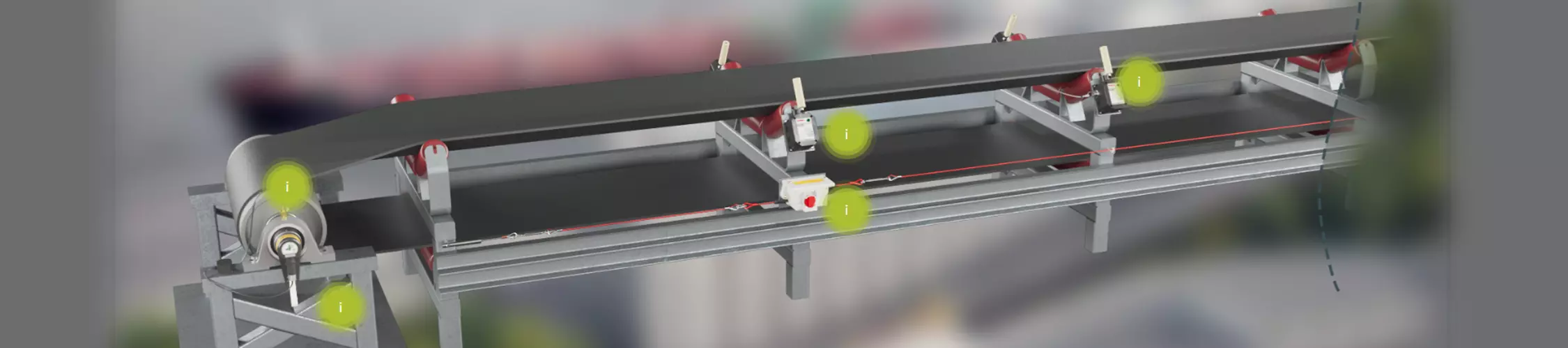

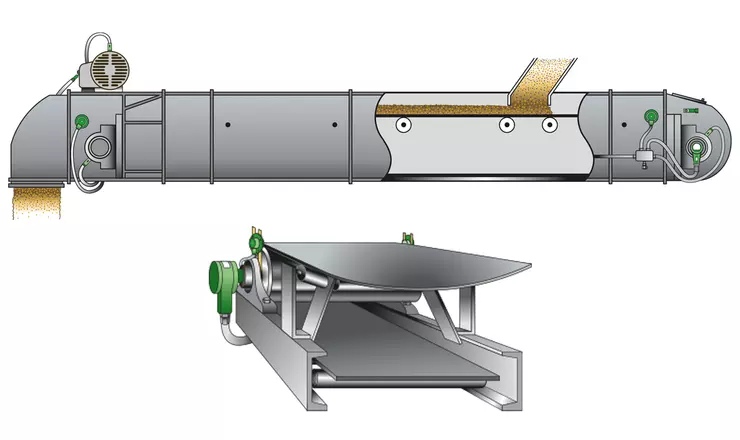

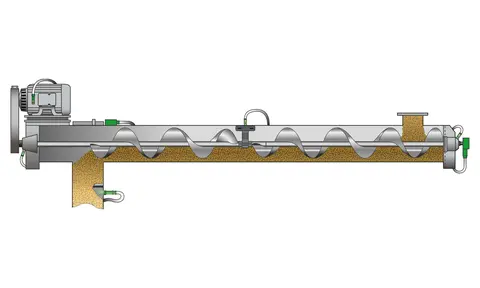

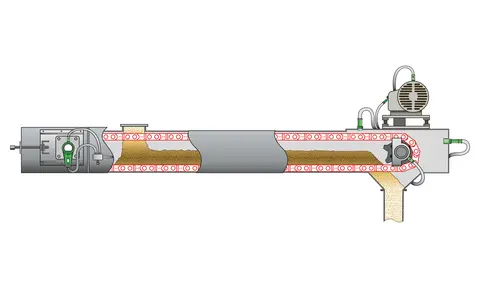

The Bulldog alignment and rip detection switch is an electro-mechanical system designed to detect dangerous misalignment of the conveyor and also detection of belt tear damage. The switch will detect horizontal misalignment of belts when contact is made with the roller, the roller arm will be forced to pivot by the belt activating a switch at 20º to trigger an alarm, and 35º to trigger a shut down procedure of the conveyor. The sensors are usually installed in pairs on opposite sides of the belt.

A steel flexible wire is set below the running conveyor belt approx 20-30mm attached by a rare earth magnet at each end. If the belt is ripped or damaged the wire is pulled away releasing the magnet connection which in turn will activate a switch.