Binswitch Elite Capacitive Sensor

Detects level or plug situations for bulk granular solids or liquids in tanks, bins, or silos and can be used as a plug or choke detector in chutes, conveyors and elevator legs.

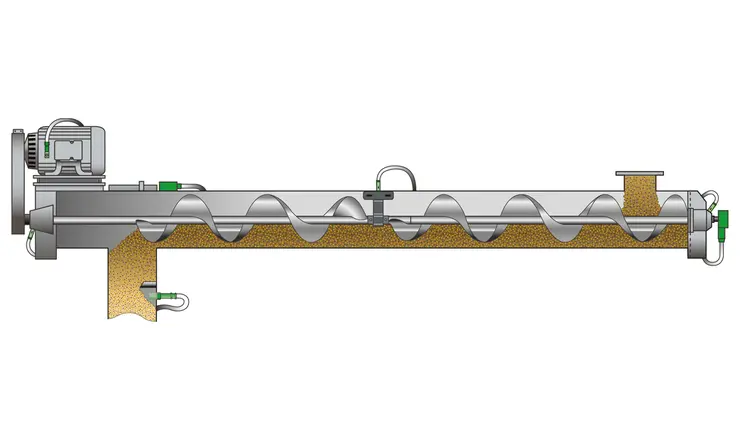

4B has a wide range of sensors for monitoring the various parts of your screw conveyor. The most common areas for monitoring include: bearing temperature, speed / motion, level / plug indication and door / gate position.

All of 4B's sensors can be connected to our hazard monitoring systems.

Detects level or plug situations for bulk granular solids or liquids in tanks, bins, or silos and can be used as a plug or choke detector in chutes, conveyors and elevator legs.

Overheated bearings are one of the main risk factors for dust explosions in bucket elevators and need to be closely monitored.

4B offers a range of Atex, CSA and IECEx certified bearing temperature sensors and compatible monitoring systems.

4B inductive proximity sensors are designed to detect shaft speed, shaft position, gate position or object presence. No contact is made between the sensor and the target being monitored.

View our full Electronics Catalogue here.

4B's line of speed switches includes: proximity, inductive, zero speed, stop motion and rotary encoders to monitor dangerous belt slip, underspeed or stop conditions on conveyors, bucket elevators and any other shaft driven machinery. Our non-contacting sensors can be used to detect screw conveyor flights, elevator bucket bolts and other moving ferrous targets. Speed switches can be connected to a PLC or to one of 4B’s hazard monitoring systems to provide alarm and/or shutdown of your machinery when dangerous conditions are detected.

View our full Electronics Catalogue here.

The Watchdog Super Elite (WDC4) is easy to install and simple to set-up. The system processes signals from sensors for belt misalignment, belt speed & slip, continuous bearing temperature, pulley misalignment and plug conditions for bucket elevators or belt conveyors. When an alarm is detected it will sound an alarm and provide shutdown control of the elevator/conveyor and feeding system.

A 3.5” LCD screen displays the entire system status at a glance. Password protected controller settings can be set up either directly on the LCD screen, or by a PC application and transferred to the WDC4 via an SD card.

The Watchdog Super Elite can be connected directly to a PLC using the Modbus TCP/IP protocol, or integrated into HazardMon.com®. This secure cloud based solution provides live system status, graphs and historical data that is viewable on any web-enabled device (smart phone, tablet, desktop PC).

The T500 Elite Hotbus™ is a serial communications system designed to monitor up to 256 sensors for combined belt alignment, belt speed, continuous bearing temperature, pulley alignment, level indication (bin / silo) and plug conditions on bucket elevators and conveyors. With automatic machine shutdown capability and PLC / PC compatibility, this advanced microprocessor based system offers low cost installation, versatility and easy system expansion. Logging and trending software is also available for historic data analysis and preventative or predictive machine maintenance.

HazardMon.com® is a secure cloud based hazard monitoring solution providing status notifications and data logging for bucket elevators and conveyors. Live system status, graphs and historical data can be viewed on any web-enabled device (smartphone, tablet PC, desktop or laptop computer). Emails can be sent to notify users whenever a change in the system's health is detected. An automated maintenance feature allows site operators to verify that all sensors on the system are operational and working correctly.

Unique low cost alarm/indicator panel for use with any 4B NTC-type temperature sensors. ADB810, WDB70, and WDB810 series sensors are recommended.

The T400N ELITE is able to accept signals from up to 8 NTC sensors (zones), which are separated into two groups of 4 zones. Each group of sensors is able to cause alarm and shutdown of individual machine when hazardous conditions are detected. There is a total of 2 Alarm and 2 Stop relays. The control unit is housed in a self contained wall mounting enclosure. A test push button on the lid of the control unit provides for full system verification. Alarm and status LEDs provide means of quick location of the alarm condition, and voltage free relay contacts provide separate alarm and shutdown control. An alarm mute push button is provided on the lid of the control unit and additional connections are provided for an external alarm mute functionality. A rotary switch is used to select the temperature alarm value.

HazardMon.com® is a secure cloud based hazard monitoring solution providing status notifications and data logging for bucket elevators and conveyors. Live system status, graphs and historical data can be viewed on any web-enabled device (smartphone, tablet PC, desktop or laptop computer). Emails can be sent to notify users whenever a change in the system's health is detected. An automated maintenance feature allows site operators to verify that all sensors on the system are operational and working correctly.

Hazardmon.com works in conjunction with 4B's Watchdog Super Elite™, T500 Elite Hotbus™ & IE-Node control systems for bucket elevators and conveyors. Both multi-function systems are specially designed to monitor equipment for belt misalignment, belt speed, continuous bearing temperature, pulley alignment, level and plug conditions.

New version of Hazardmon can be found on: https://new.hazardmon.com/