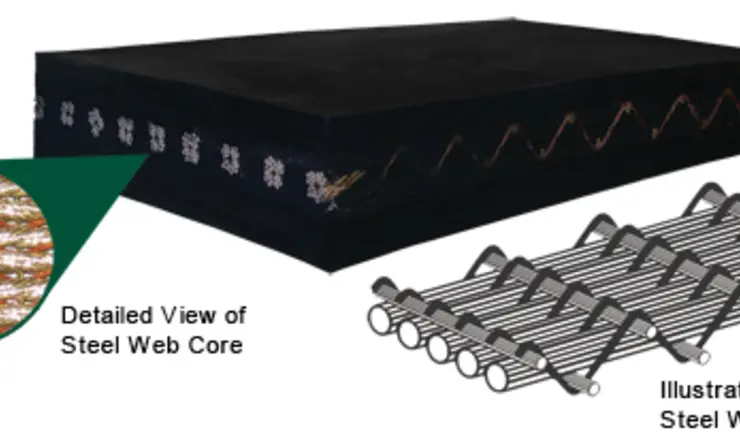

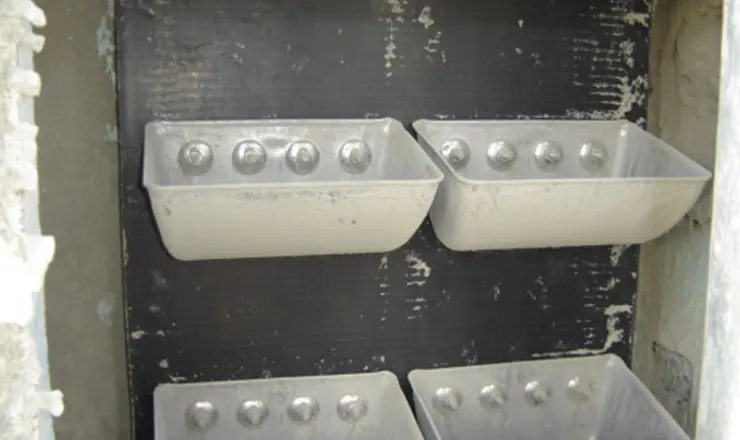

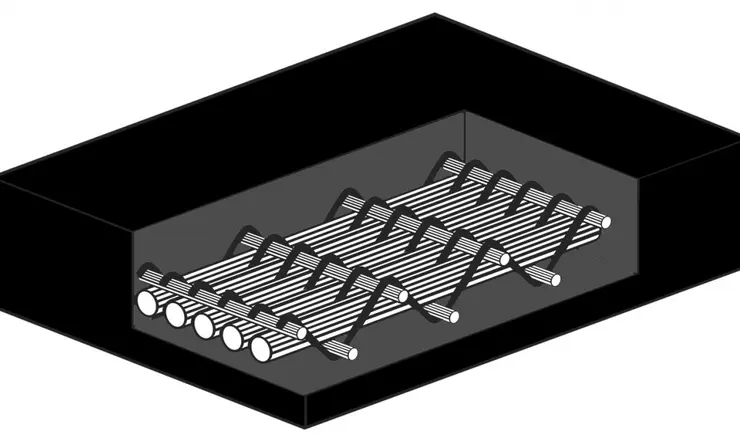

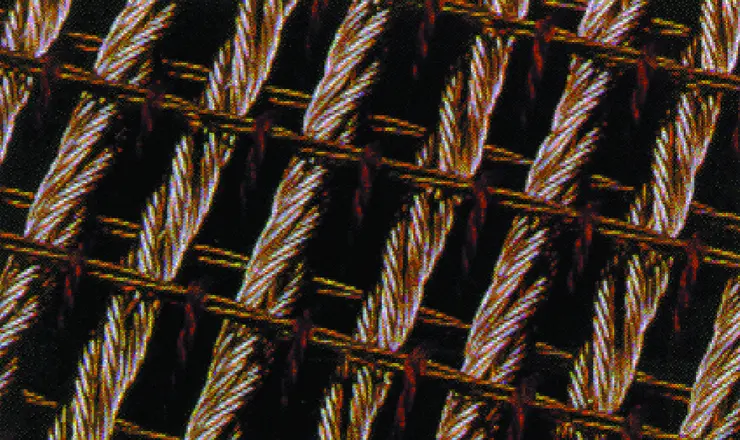

4B's STEEL WEB belt is a rubber elevator belt with a special steel cord core. The cords provide low elongation with high elasticity in the length, and cross rigidity in the width. The built-in elasticity allows running over slightly crowned pulleys which greatly improves belt tracking. The rigid weft cords act as a barrier to ripping and tearing which increases the holding ability for the bucket bolts. This produces a good cross rigid belt resulting in excellent straight tracking characteristics. In contrast, most conventional steel cable belts lack elasticity and consequently have to run over truly flat, cylindrical pulleys which increases the risk of belts off tracking.

- Tall high capacity elevators, hot industrial materials

- Minimum stretch

- 3+3 or 4+4 covers

- Temperature resistant up to 130C continuous

Specifications

| Belt type | Strength | Covers | Belt Thickness | Minimum Pulley Dia. | Approximate Weight | |

| SWB | (N/mm) | (mm) | (mm) | (mm) | (kg/sqm) | |

| SW 800 | 800 | 3+3 | 12.0 | 500 | 18.0 | |

| SW 1000 | 1,000 | 3+3 | 12.0 | 500 | 18.7 | |

| SW 1250 | 1,250 | 4+4 | 13.0 | 630 | 21.0 | |

| SW 1400 | 1,400 | 4+4 | 15.0 | 630 | 24.5 | |

| SW 1600 | 1,600 | 4+4 | 15.0 | 630 | 25.0 | |

| SW 1800 | 1,800 | 4+4 | 15.0 | 630 | 25.5 | |

| SW 2000 | 2,000 | 4+4 | 15.0 | 800 | 26.0 | |

| SW 2500* | 2,500 | 5+5 | 18.0 | 800 | 32.5 | |

*on special order

Other types on demand:

Type 1 - highly abrasion resistant with a maximum service temperature of 100°C

Type 2 - abrasion resistant with a maximum service temperature of 130°C. Continuous short peaks at 150°C

Type 3 - oil and fat resistant, anti static and flame retardant ISO 340