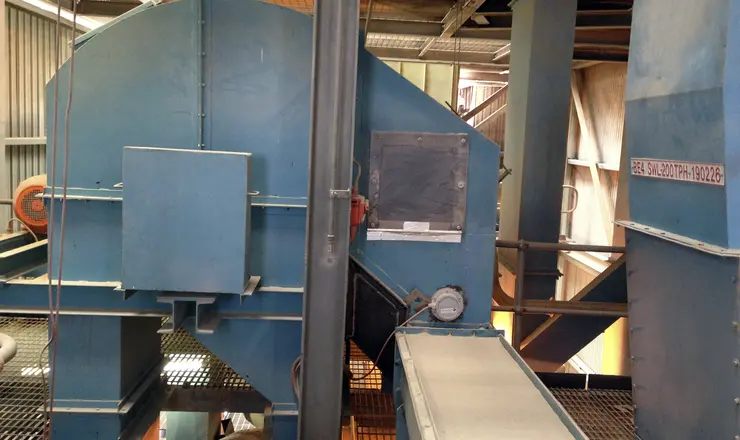

Elevator upgrade at Sun-Rice Australia. Provided engineering, design guidance and component supply with changing old-style fabricated elevator buckets to modern polymer SPS buckets. Elimination of backlegging and chute wear.

Customer had undertaken a “continuous improvement” programme of upgrading older types of steel elevator buckets for modern efficient types of polymer elevator buckets. The older style fabricated steel buckets were of a similar geometry to CC type buckets. So, trials commenced utilizing several types of CC poly buckets, all of which proved to be inefficient and backlegged rice so significantly throughput was decreased by 40TPH and wear damage to the casings had occurred

through the re-circulation of materials.

4B was contacted and asked to consult and were engaged to provide a solution, which included providing suitable system belt speeds, adjustments to outlet chutes and selecting a suitable polymer style bucket that would not compromise the capacity of the system and operations.

Customer had undertaken a “continuous improvement” programme of upgrading older types of steel elevator buckets for modern efficient types of polymer elevator buckets. The older style fabricated steel buckets were of a similar geometry to CC type buckets. So, trials commenced utilizing several types of CC poly buckets, all of which proved to be inefficient and backlegged rice so significantly throughput was decreased by 40TPH and wear damage to the casings had occurred

through the re-circulation of materials.

4B was contacted and asked to consult and were engaged to provide a solution, which included providing suitable system belt speeds, adjustments to outlet chutes and selecting a suitable polymer style bucket that would not compromise the capacity of the system and operations.

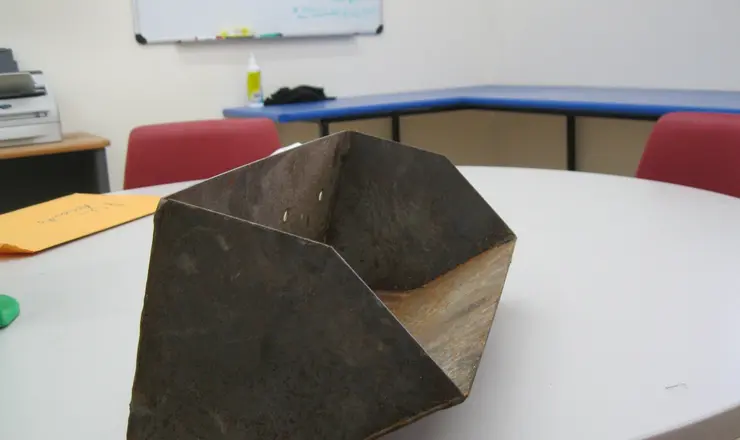

A complete and thorough evaluation was undertaken of belt and pulley speeds, discharge efficiencies and actual volumetric filling factors of individual buckets. This was then assessed against the existing discharge chute design, which favoured the older style steel fabricated buckets. In particular the actual centripetal acceleration that was expected to occur with the modern polymer buckets was calculated and then cross referenced with the vertical and horizontal distances available within the existing discharge chute.

The combined results provided 4B Engineers with the exact information required for selecting a suitable bucket, adjusting the angle of the outlet chute, applying a belt speed reduction. Which increased individual volumetric filling, and reduced backlegging.

A complete and thorough evaluation was undertaken of belt and pulley speeds, discharge efficiencies and actual volumetric filling factors of individual buckets. This was then assessed against the existing discharge chute design, which favoured the older style steel fabricated buckets. In particular the actual centripetal acceleration that was expected to occur with the modern polymer buckets was calculated and then cross referenced with the vertical and horizontal distances available within the existing discharge chute.

The combined results provided 4B Engineers with the exact information required for selecting a suitable bucket, adjusting the angle of the outlet chute, applying a belt speed reduction. Which increased individual volumetric filling, and reduced backlegging.

The versatile SPS bucket provided the best results due to wide range of speeds that it can be utilized in on most elevator applications. In this instance the elevator had been designed around an old bucket that was now considered inefficient in performance and costly to manufacture.

The 4B solution was able to deliver the benefits the customer was looking to achieve with their “continuous improvement” programme. The elimination of the backlegging, and chute wear whilst maintaining origin design capacity.

The versatile SPS bucket provided the best results due to wide range of speeds that it can be utilized in on most elevator applications. In this instance the elevator had been designed around an old bucket that was now considered inefficient in performance and costly to manufacture.

The 4B solution was able to deliver the benefits the customer was looking to achieve with their “continuous improvement” programme. The elimination of the backlegging, and chute wear whilst maintaining origin design capacity.