The M100 Stopswitch is a simple inductive shaft speed monitoring device. The self-contained unit has a single set point, which signals when the shaft has stopped rotating. It can be used for process control, motion detection and stopped shaft indication. An inductive sensing device located in the nose of the M100 enclosure will detect a metal target. This target can be an existing bolt head or device attached to a shaft. The M100 Stopswitch requires no calibration and provides an output when the shaft has stopped rotating.

Product Features

- Stopped Motion Monitor

- Inductive Proximity Sensor

- Single Trip Set Point

- Totally Sealed Construction (Submersible)

- Non-Contacting and Fail-Safe

Electronics Application

Belt Conveyor

Belt Conveyor

Bucket Elevator

Bucket Elevator

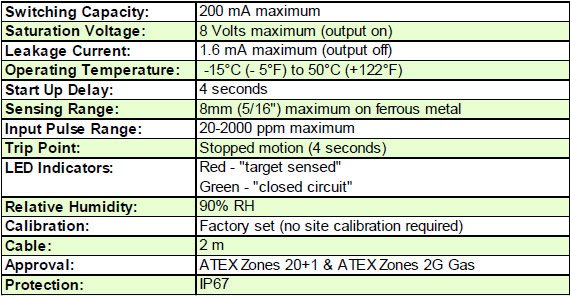

Specifications

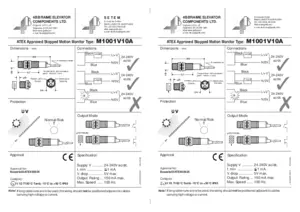

Part Numbers & Accessories:

- M1001V10A - Stopswitch M100

- M1001V10AG - Stopswitch M100 (gas approved)

- WG1-8A-BR - Whirligig (target/bracket/guard)

- MAG2000M - Mag-Con Magnetic Connector for Whirligig

TECHNICAL SPECIFICATIONS

M100 Stopswitch – Detects Dangerous Stop Conditions