The M300 Slipswitch is an easy-to-use inductive proximity shaft speed monitoring device with an adjustable 0 - 30 second start-up delay, all housed in a 30 mm diameter moulded body. The self-contained unit has a single set point, which signals when the shaft speed has dropped by 20% of normal running speed. It is used for detecting dangerous slow down and underspeed conditions on conveyors, bucket elevators, air locks, mixers, fans, grinders and many other machines.

No connection is necessary between the sensor and the equipment being monitored. The proximity sensor detects a stud or bolt mounted on a shaft, or other suitable target. Ideally, the target should be of ferrous metal, but non-ferrous metal will be detected at a shorter range. Maximum range of ferrous targets is 8 mm (5/16”) and for non-ferrous targets is 5 mm (6/16”), assuming a 20 mm (3/4”) diameter target. Smaller targets may be used but operating distances will be reduced.

- ATEX and IECEx Zone 20 (Dust) and Zone 0 (Gas) Approved

- Signals underspeed for bucket elevators, conveyors and all rotating machinery

- Inductive proximity sensor in 30mm diameter housing, which detects rotating metal target

- 20% underspeed set point

- 2 wire & 5 wire versions available

- Easy and reliable calibration procedure by using a magnet

- Non-contacting & failsafe

- Compatible with the Whirligig speed sensor mount

Belt Conveyor

Bucket Elevator

Specifications

| | ||

| Specification | Value | |

| Supply Voltage: | 24 to 240 VAC/VDC | |

| Supply Fusing: | Supply to be fused at 500mA maximum | |

| Switching Capacity: | M3003V10AI: 100 mA maximum; M3007V10AI: 60VDC/VAC, 3A | |

| Saturation Voltage: | M3003V10AI: 5.5 Volts maximum (output on); M3007V10AI: N/A | |

| Leakage Current: | M3003V10AI: 1.6 mA maximum (output off); M3007V10AI: N/A | |

| Ambient Temperature: | 5°F (-15°C) to +122°F (+50°C) | |

| Output State: | M3003V10AI: FET; M3007V10AI: SPCO relay | |

| Sensing Range: | 5/16” (8 mm) maximum on ferrous metal at 77°F (25°C) | |

| Input Pulse Range: | 10 to 3,600 pulses per minute (PPM) maximum | |

| Start-Up Delay: | Adjustable - 0 to 30 seconds | |

| Trip Point: | 20% below set speed | |

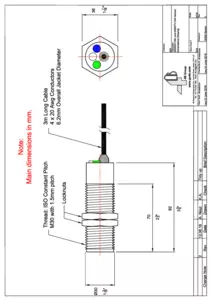

| Enclosure: | Nylon - ISO threaded 30 mm by 1.5 mm pitch | |

| Relative Humidity: | 90% RH | |

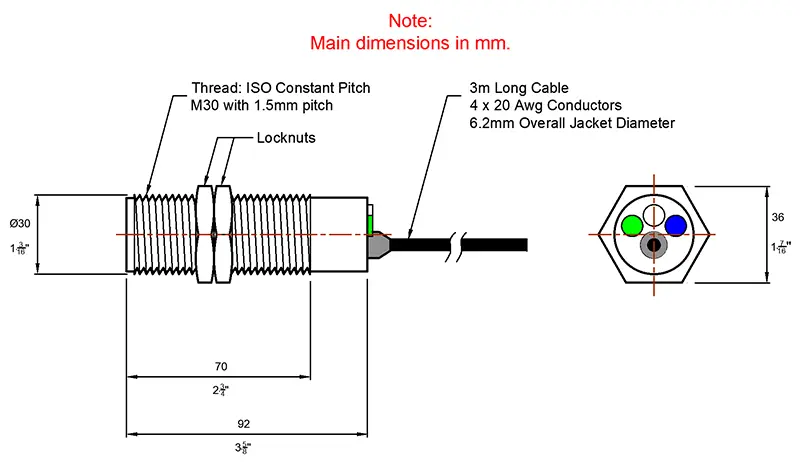

| LED Indicators: | Blue - Target Sensed, Green - Set Speed | |

| Connections: | 2 wire (M3003V10AI) or 5 wire (M3007V10AI), 3m long cable. | |

| Protection: | IP66 |

Downloads

Accessories

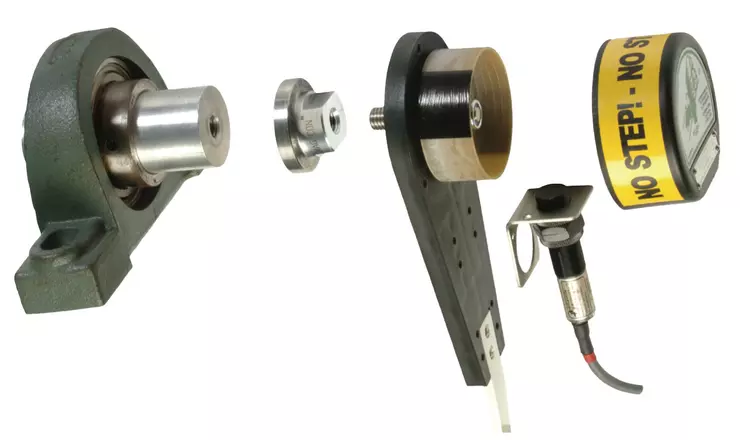

Whirligig®

The Whirligig® is a fully guarded target for easy mounting of motion sensors. It is a universal shaft sensor mount suitable for all industry standard cylindrical or DIN style inductive sensors including 4B's M100, M300, and M800 speed switch sensors.

The sensor bolts to the Whirligig base plate and the complete assembly either bolts to the machines shaft through a M12 tapped hole, or is connected magnetically using 4B’s patented Mag-Con™ adaptor. Shaft or machine vibration does not affect the performance of the sensor, as the whole assembly moves with the shaft. With the Whirligig, installation of speed sensors is now simple, safe and reliable.

SpeedMaster™

The SpeedMaster™ with Pulse Pilot is the only device that accurately tests the calibration of a speed switch, and allows testing of the 10% alarm and 20% shutdown features of the sensor while installed on the machine shaft.

The SpeedMaster™ operates in two modes. Input mode is used to measure the pulse rate at normal speed. Output mode will allow the user to simulate belt underspeed for testing purposes.

The Pulse Pilot fits between the gap between the sensor and the target. The Pulse Pilot will have no effect on the operation of the speed switch until it is connected to the SpeedMaster™ and set to Output mode.

4B Speed Relay (USR)

The Speed Relay is a microprocessor controlled digital speed monitor for use with 2, 3, 4 wire NPN/PNP sensors, 4B’s WDA range of sensors or Contact sensor inputs, with a user programmable electromechanical relay and PhotoMOS Solid State Relay (SSR) outputs. The Speed Relay has a 160x80 pixel LCD display to provide information, and 3 front panel buttons to program settings.

4B Sensor Mounting Kit

The 4B Sensor Mounting Kit is able to securely mount barrel sensors in position, including 4B’s range of 18 & 30mm wide inductive sensors.

Made of Stainless Steel and Nylon 66, giving corrosion resistance as well as abrasion resistance and high melting points, the brackets are ideal for harsh environments.

A flexible mounting head and foot can be rotated independently before being locked in the required position using the supplied screws.

Monitors

X400 Elite Alarmswitch

The X400 Elite is a microprocessor controlled low cost alarm indicator panel for use with level indicators, hazard controls and limit switch sensors. The X400 accepts signals from different sources in up to 8 zones, and is able to cause alarm and shutdown of the machine when an alarm condition has been detected. Alarm and status LEDs on the lid of the X400 provide quick location of alarm conditions. Alarm muting can be performed at the panel or by an optional remote push button to silence external alarms. If the system is muted, it will automatically reactivate when a new alarm is triggered. Testing can also be activated at the panel, providing full system verification.

FAQ's

In the product documentation, there is a reference to "load". What is it and how big does it have to be?

Load is the input circuit of the PLC, relay coil or anything else the sensor output if fed into. the load need to limit the current through the M300 sensors to within the specified limit.

When checking the 2 wire M300 with a voltage meter, it is always showing the supply voltage no matter if the shaft is turning or not. Why is the sensor not changing states?

The sensor will not function correctly until a load is connected to it, maximum current through the sensor is provided in the product manual.

How many wires are needed to run the 5 wire version of the M300?

Three are needed to run the sensor, talk to our technical staff or refer to the product manual for more details.

How do you calibrate the M300?

The calibration of this sensors is a very easy procedure for which you will need a magnet, which is supplied with the sensor. Please refer to the operation manual for the detailed instructions.