- Force Activated Belt and Pulley Alignment Sensor

- Instantaneous Misalignment Indication

- Hardened Stainless Steel Contact Face

- External Test Feature

- Output LED Indication

- Not a Rub Block

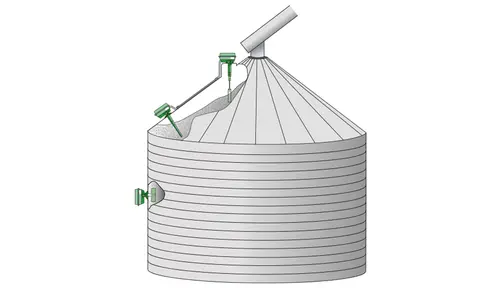

Alignment Sensors

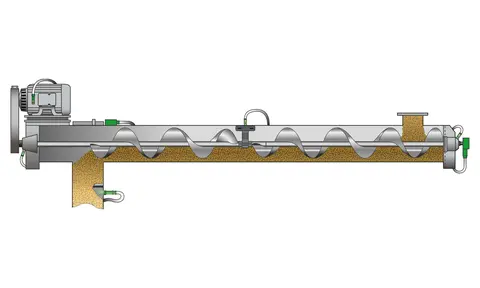

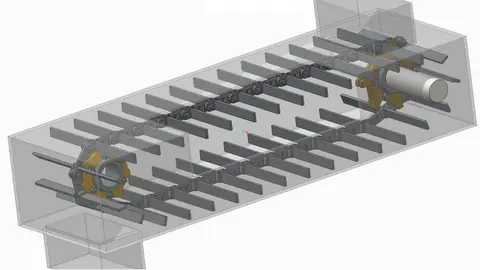

4B's line of sensors and switches are designed to for detecting (mis)alignment and motion for bucket elevators, belt conveyors, drag chain conveyors as well as screw conveyors.

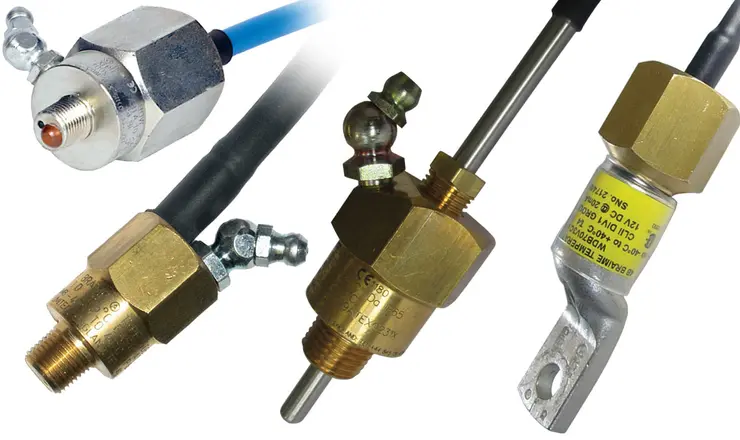

- Magnetic Proximity Belt Speed and Belt Alignment Sensor

- Adjustable Sensing Range 25mm to 75 mm

- LED Indication

- Mounting Bracket Included

- ½” NTP Conduit Entry

- Stainless Steel Construction

- High Temperature Version Available

- IP66 Protection

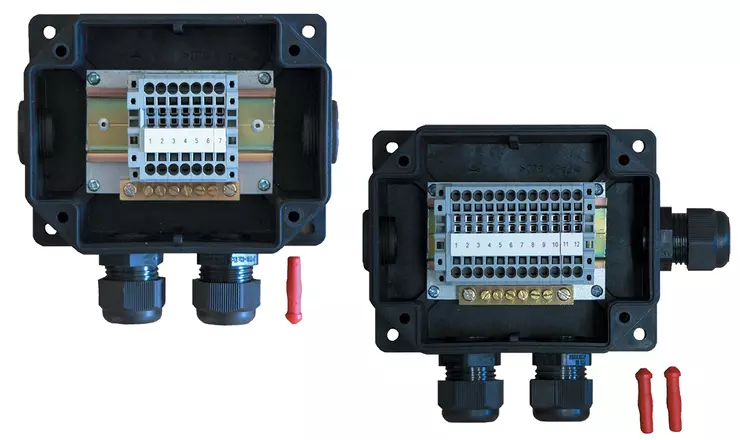

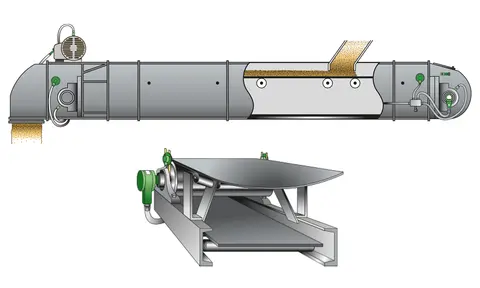

- Conveyor Belt Misalignment & Rip Detection System

- Electro-mechanical system designed to detect dangerous misalignment of the conveyor and also detection of belt tear damage

- Triggers an alarm at 20º and a shutdown of the machine at 35º

- Easy installation

- Robust design

- No calibration required

- Nylon rollers as standard; stainless steel rollers available on request

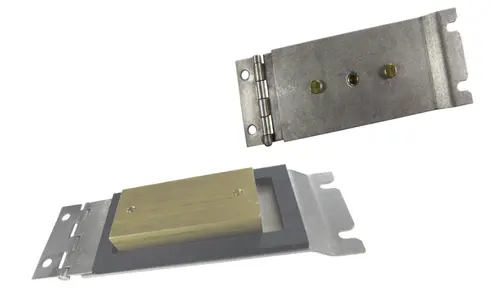

- Brass Rub Block Belt Misalignment Sensor

- Belt Misalignment Detection

- Simple Installation

- Solid Brass Construction (No Moving Parts)

- Temperature-Activated by Friction

- Applicable bearing sensors - not included in kit:

ADB91MV3AI/D2 (4-20mA), ADB20V3CAI/D2 (NTC), ADB29V3CAI/D2 (PT100) & ADBMIL1V4C/D2 (4-20mA) - External Sensor Testing Capability (ADB Tester)

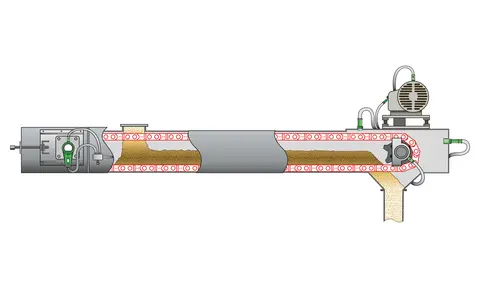

- Magnetic Proximity Belt Speed and Belt Alignment Sensor

- Detects Moving Steel Ferrous Targets

- Adjustable Sensing Range of 25 – 75mm

- Not Affected by Material Build Up

- Stainless Steel Construction

- High Temperature Version Available

- Rugged housing for the most arduous environments

- Fail safe magnetic sensor immune to build up of material

- Powerful sensing range of 12 – 50mm, easily adjusted on the sensor or at the control unit

- Links direct to PLC or to independent control unit A400 Elite or Watchdog Elite