- Robust, IP66 stainless steel enclosure

- 7” Colour touchscreen display with intuitive GUI

- Supports multiple machine configurations

- Common ALARM and STOP relay

- Can be configured for up to: 100 Machines, 64 IE-Nodes, 1024 Devices

- Remote view and control over network

- Multi-user access control

- Active alarm and alarm history

- Change log

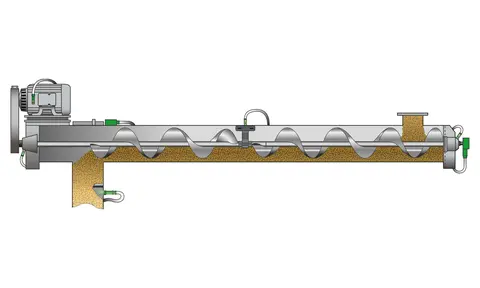

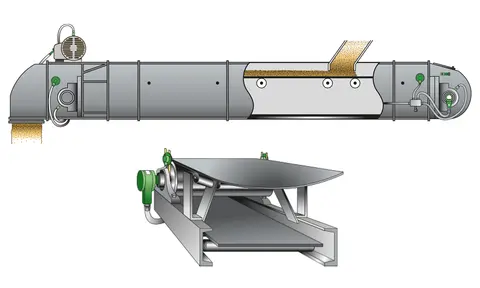

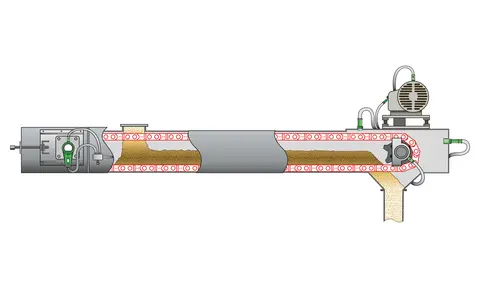

Hazard Monitors

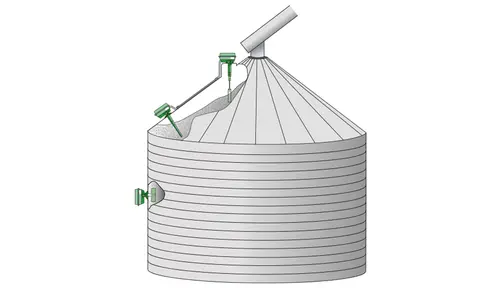

4B has an extensive range of CSA / ATEX / CE / IECEx approved hazard monitoring systems specifically designed for bucket elevators and conveyors in dust hazard environments. As an industry leader in developing high quality, innovative, and dependable electronic components, 4B can recommend the ideal system to suit your requirements and budget.

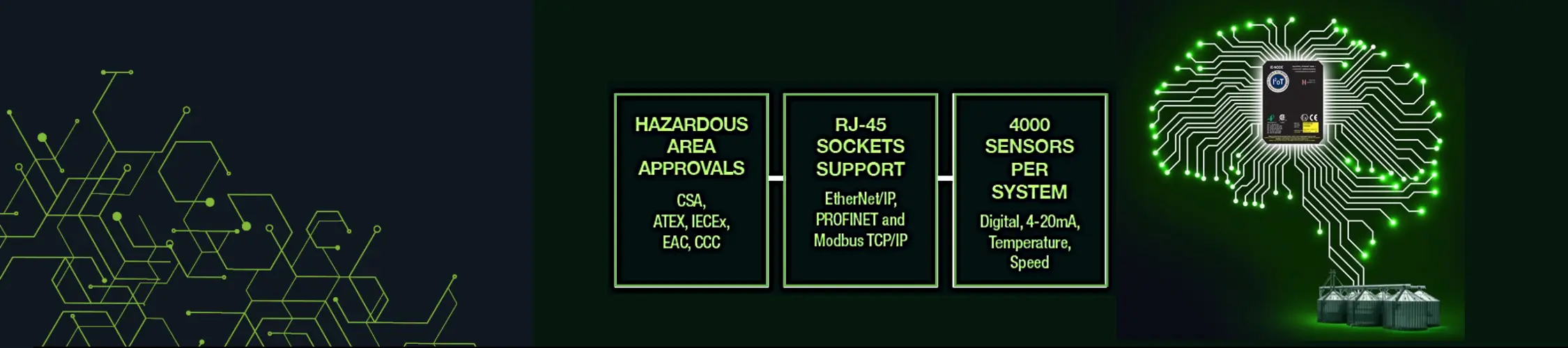

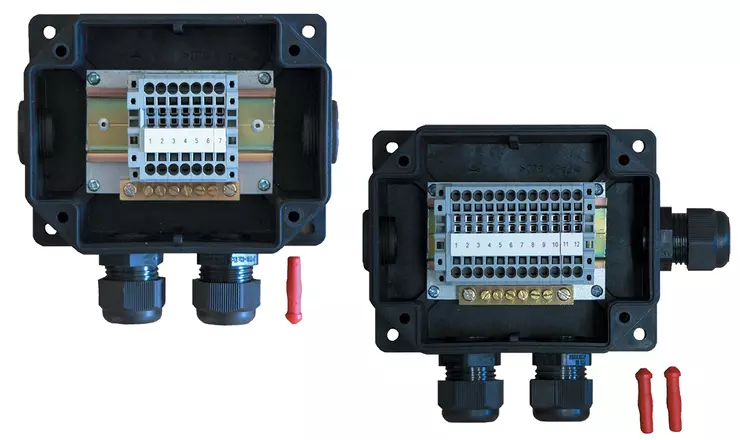

- Sensor Interface for PLC’s & Automation Systems

- Supports PROFINET, EtherNet/IP and Modbus TCP/IP protocols

- Up to 16 total sensor inputs with available expansion boards

- Configurator software for easy network setup and visual overview of all devices

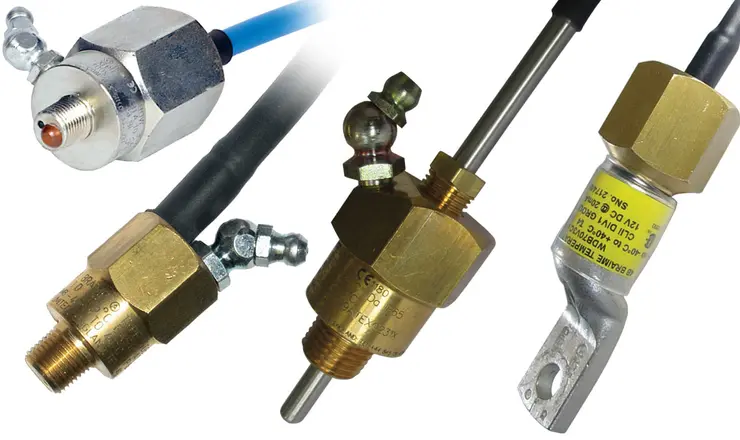

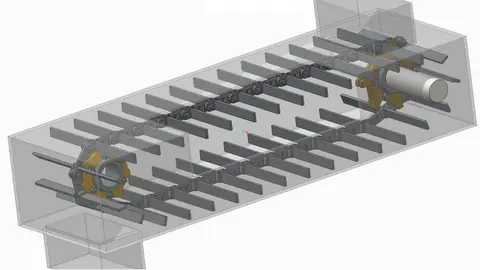

- Belt Speed Monitoring (Single and Differential Speed)

- Belt Alignment Monitoring (Contact, Pulsed and Rub Blocks)

- Bearing Temperature Monitoring (NTC)

- Pulley Alignment Monitoring

- Plug Condition Monitoring

- Acceleration Monitoring

- Jog Prevention (Limited Number of Elevator Starts per Minute)

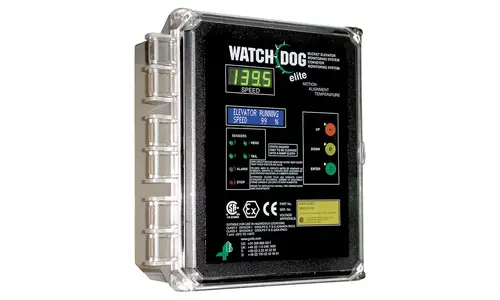

- 3.5” Full-colour Graphics LCD Display

- SD Card for Settings Save, Restore and Transfer, as Well as Data Logging and Firmware Updates

- Ethernet RJ45 Port for Modbus TCP and Hazardmon.com Connectivity

- Hazardmon.com Support for Real-time Remote Monitoring and Historical Data Analysis

- Designed for Multiple Elevator Legs or Conveyors

- Monitors: Belt Speed, Belt Alignment, Bearing Temperature, Pulley Alignment, Bin/Silo Level Indication & Plug Conditions

- Serial Network System, Accepts Inputs from 256 Sensors

- LCD Displays System Status

- HazardMon.com Cloud Based Monitoring

- Monitors up to Eight Temperature Zones

- Can Monitor Two Separate Machines via 2 x Alarm and 2 x Stop Relays

- Selectable Alarm Temperature Level

- Configurable Alarm and Stop Delays

- LED Alarm Indication and Power Status

- Alarm Mute - Automatic Reactivation on New Alarm

- Test Feature – Externally Controlled Test Facility

- Dust Hazard Approved

- Monitors 8 zones with up to 6 PTC sensors in each zone (48 total)

- Configurable Alarm and Stop Delays

- LED Alarm Indication and Power Status

- Alarm Mute - Automatic Reactivation on New Alarm

- Test Feature – Externally Controlled Test Facility

- Bucket Elevator Belt Alignment Monitoring

- Uses up to 4 WDA or BAP Magnetic (Reluctance) Alignment Sensors

- Monitor Two Bucket Elevators or Top & Bottom of One

- 2 Separate Alarm Relays

- 2 Separate Stop Relays

- Push Button Testing Feature

- Bucket Elevator or Conveyor Belt Alignment Monitor

- Uses up to 4 Touchswitch Alignment Sensors

- Monitor Up To Two Bucket Elevators or Belt Conveyors

- 2 Separate Alarm Relays

- 2 Separate Stop Relays

- Push Button Testing Feature

- Centralized Alarm Monitoring for up to 8 Zones

- Multiple Alarm Inputs from Different Sensors

- LED Alarm Indication

- Alarm Mute - Reactivation on New Alarm

- Push Button Testing Feature

- Optional PLC Board

- Designed for One Elevator Leg or Conveyor

- Monitors: Belt Speed, Belt Alignment, Bearing Temperature, Pulley Alignment & Plug Conditions

- Fully Programmable via Front Panel Touch Buttons

- LCD Displays System Status & Belt Speed

- PC Logging & Trending Software Available