Subic Bay Freeport Grain Terminal. Changeover of 4B chain and 4B nylon flights to replace competitor's inferior plastic flights and chain. Resolved problems with bending flights, wear issues and failures. Maintenance has been made a lot easier and productivity increased.

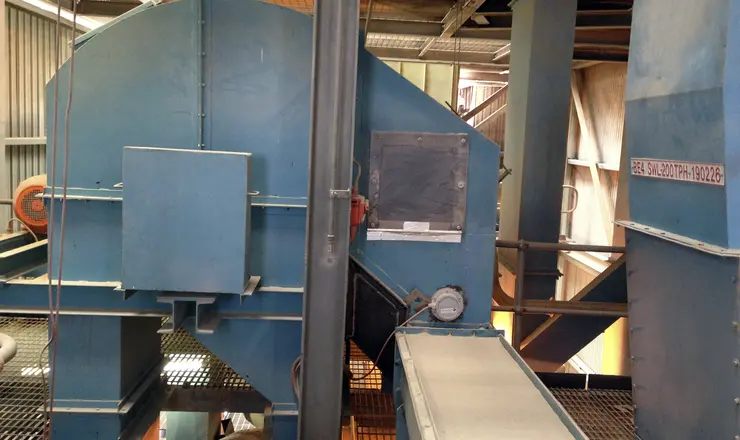

The original chain conveyor equipment for Subic Bay Freeport Grain Terminal was supplied by a competitor and their original 142 pitch forged chains with plastic flights installed.

It was found that the installation was a big problem for the customer with many production and maintenance issues. The inferior and thin flights transpired to wear easily, bend and break often. The construction of the flight attachments was too weak, and subsequently that caused the flights to break loose from the chain link. This lead to blockages in production and major maintenance issues. Not only needed the flights be replaced, but the links too. Resulting in costly downtime and maintenance costs. The original sprockets were also difficult to remove and maintain.

The original chain conveyor equipment for Subic Bay Freeport Grain Terminal was supplied by a competitor and their original 142 pitch forged chains with plastic flights installed.

It was found that the installation was a big problem for the customer with many production and maintenance issues. The inferior and thin flights transpired to wear easily, bend and break often. The construction of the flight attachments was too weak, and subsequently that caused the flights to break loose from the chain link. This lead to blockages in production and major maintenance issues. Not only needed the flights be replaced, but the links too. Resulting in costly downtime and maintenance costs. The original sprockets were also difficult to remove and maintain.

We had the chance to introduce our 4B Bolt ‘N’ Go chain and flight system. The customer was impressed by the concept and purchased a few hundred meters of 4B Bolt ‘N’ Go chain to go on their conveyors.

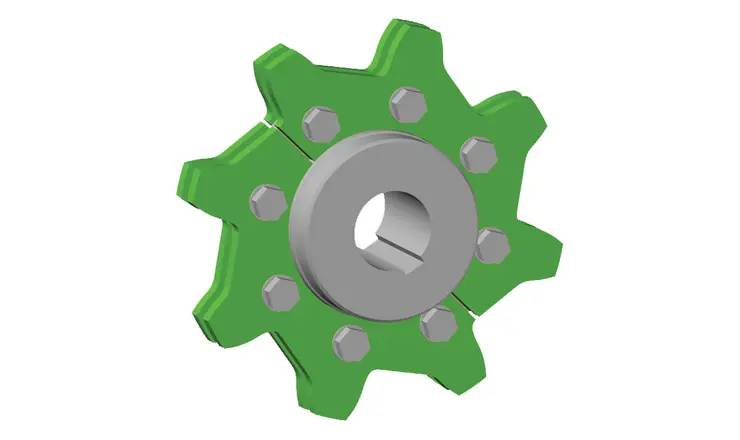

The 4B patented Bolt ‘N’ Go design with much thicker virgin nylon material flights was used to upgrade the existing chain conveyors, offering a much more durable solution than some other inferior plastic flights. Using hollow pin design and anti-rotation lugs on the links, the Bolt ‘N’ Go chain system offers a safe and reliable design that is easy to maintain as well and will save the customer a lot of costs and hassle in the long run.

We had the chance to introduce our 4B Bolt ‘N’ Go chain and flight system. The customer was impressed by the concept and purchased a few hundred meters of 4B Bolt ‘N’ Go chain to go on their conveyors.

The 4B patented Bolt ‘N’ Go design with much thicker virgin nylon material flights was used to upgrade the existing chain conveyors, offering a much more durable solution than some other inferior plastic flights. Using hollow pin design and anti-rotation lugs on the links, the Bolt ‘N’ Go chain system offers a safe and reliable design that is easy to maintain as well and will save the customer a lot of costs and hassle in the long run.

- All problems have now been resolved. - No flights bending, wearing or failures.

- Easy maintenance and removal when the correct time comes.

- 4B flights are slightly deeper than the competition’s, allowing some productivity and capacity gains.

- No downtime! Increased productivity! Easy maintenance!

- 4B sprockets were also used and found to be much easier to change over due to the segmental system.

- The customer was very impressed!

- All problems have now been resolved. - No flights bending, wearing or failures.

- Easy maintenance and removal when the correct time comes.

- 4B flights are slightly deeper than the competition’s, allowing some productivity and capacity gains.

- No downtime! Increased productivity! Easy maintenance!

- 4B sprockets were also used and found to be much easier to change over due to the segmental system.

- The customer was very impressed!