GB - Spidex™ Buckets

Bottomless Elevator Buckets

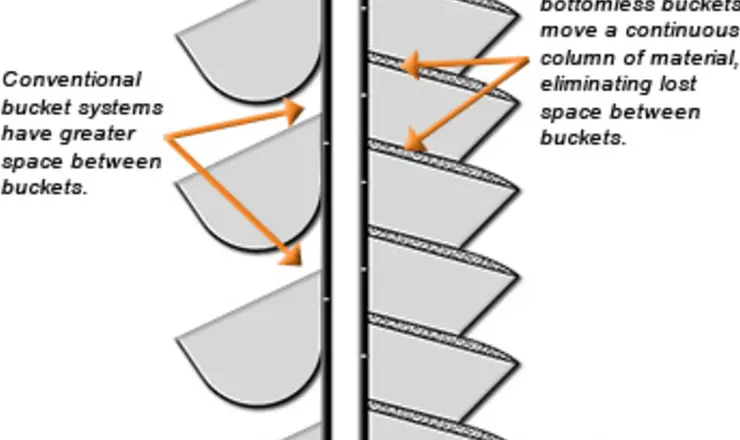

High capacity bottomless elevator bucket system. GB Spidex™ buckets are closely spaced with a series of buckets without bottoms followed by one bucket with a bottom. The material is lifted in a continuous column and the carrying space normally wasted between conventional buckets is fully utilized to achieve much greater capacity. The buckets pick up and discharge conventionally, but care must be taken in the design of the boot and the head.

Product Features

- Double existing capacity

- Elevator buckets are closely spaced & product is elevated in an almost continuous column

- Self-cleaning - ideal for sticky materials

- Pressed seamless steel

Material

Stainless Steel,

Steel

Use by Industry

Agricultural,

Industrial

Use by Product

Cereals,

Pellets & Light Agricultural,

Sticky Materials,

Cement

Specifications

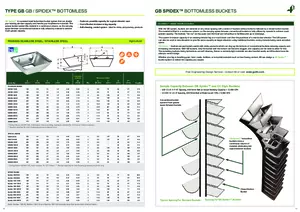

| GB bucket | A | B | C | T | Weight | Capacity (L) | Holes | E | F | G | Bucket Spacing | Max. | |

| STANDARD | (mm) | (mm) | (mm) | (mm) | (kg) | Z2 (total) | No. | (dia mm) | (mm) | (mm) | (mm) | Pcs/Mtr | |

| GB130-110-B | 136 | 114 | 51 | 1.5 | 0.3 | 0.5 | 2 | 8.5 | 70 | 22 | 57 | 17.5 | |

| GB130-110+B | 136 | 114 | 51 | 1.5 | 0.36 | 0.5 | 2 | 8.5 | 70 | 22 | 57 | 17.5 | |

| GB180-140-B | 185 | 139 | 65 | 1.5 | 0.45 | 1.18 | 2 | 9 | 100 | 32 | 71 | 14 | |

| GB180-140+B | 185 | 139 | 65 | 1.5 | 0.55 | 1.18 | 2 | 9 | 100 | 32 | 71 | 14 | |

| GB230-165-B | 237 | 163 | 71 | 2 | 0.83 | 2.1 | 2 | 10 | 120 | 32 | 80 | 12.5 | |

| GB230-165+B | 237 | 163 | 71 | 2 | 1.12 | 2.1 | 2 | 10 | 120 | 32 | 80 | 12.5 | |

| GB300-165-B | 305 | 166 | 80 | 2 | 1.1 | 2.75 | 3 | 10.5 | 90* | 36 | 88 | 11.4 | |

| GB300-165+B | 305 | 166 | 80 | 2 | 1.4 | 2.75 | 3 | 10.5 | 90* | 36 | 88 | 11.4 | |

| GB350-200-B | 355 | 200 | 100 | 2.5 | 1.95 | 4.75 | 4 | 11 | 90 | 42 | 111 | 9 | |

| GB350-200+B | 355 | 200 | 100 | 2.5 | 2.5 | 4.75 | 4 | 11 | 90 | 42 | 111 | 9 | |

| GB400-220-B | 410 | 218 | 115 | 3 | 2.3 | 6.91 | 4 | 11 | 100 | 45 | 125 | 8 | |

| GB400-220+B | 410 | 218 | 115 | 3 | 2.95 | 6.91 | 4 | 11 | 100 | 45 | 125 | 8 |

| GB bucket | A | B | C | T | Weight | Capacity (L) | Holes | E | F | G | Bucket Spacing | Max. | |

| SPECIAL RANGE | (mm) | (mm) | (mm) | (mm) | (kg) | Z2 (total) | No. | (dia mm) | (mm) | (mm) | (mm) | Pcs/Mtr | |

| GB215-95-B | 220 | 93 | 63 | 1.5 | 0.4 | 0.95 | 2 | 8.5 | 127 | 25 | 67 | 14.9 | |

| GB215-95+B | 220 | 93 | 63 | 1.5 | 0.5 | 0.95 | 2 | 8.5 | 127 | 25 | 67 | 14.9 | |

| GB380-165-B | 380 | 165 | 80 | 2.5 | 1.7 | 3.5 | 4 | 9 | *** | 36 | 88 | 11.4 | |

| GB380-165+B | 380 | 165 | 80 | 2.5 | 2.15 | 3.5 | 4 | 9 | *** | 36 | 88 | 11.4 | |

| GB325-190-B | 335 | 191 | 88 | 2.5 | 1.65 | 3.6 | 3 | 9 | 100 | 25 | 100 | 10.5 | |

| GB325-190+B | 335 | 191 | 88 | 2.5 | 2.11 | 3.6 | 3 | 9 | 100 | 25 | 100 | 10.5 | |

| GB400-200-B | 410 | 200 | 97 | 2 | 1.66 | 5.4 | 4 | 9 | 94 | 32 | 105 | 9.5 | |

| GB400-200+B | 410 | 200 | 97 | 2 | 2.2 | 5.4 | 4 | 9 | 94 | 32 | 105 | 9.5 | |

| GB430-200-B | 437 | 200 | 95 | 2 | 1.77 | 5.56 | 4 | 9 | 94 | 32 | 105 | 9.5 | |

| GB430-200+B | 437 | 200 | 95 | 2 | 2.3 | 5.56 | 4 | 9 | 94 | 32 | 105 | 9.5 |

| SPIDEX bucket | A | B | C | T | Weight | Capacity (L) | Holes | E | F | G | Bucket Spacing | Max. | |

| (mm) | (mm) | (mm) | (mm) | (kg) | Z2 (total) | No. | (dia mm) | (mm) | (mm) | (mm) | Pcs/Mtr | ||

| Spidex 100-90-B | 106 | 88 | 45 | 0.9 | 0.1 | 0.23 | 2 | 8.5 | 50 | 17 | 50 | 20 | |

| Spidex 100-90+B | 106 | 88 | 45 | 0.9 | 0.12 | 0.23 | 2 | 8.5 | 50 | 17 | 50 | 20 | |

| Spidex 130-110-B | 136 | 114 | 51 | 1.5 | 0.26 | 0.5 | 2 | 8.5 | 70 | 22 | 57 | 17.5 | |

| Spidex 130-110+B | 136 | 114 | 51 | 1.5 | 0.31 | 0.5 | 2 | 8.5 | 70 | 22 | 57 | 17.5 | |

| Spidex 180-140-B | 185 | 139 | 65 | 1.5 | 0.41 | 1.08 | 2 | 9 | 100 | 32 | 71 | 14 | |

| Spidex 180-140+B | 185 | 139 | 65 | 1.5 | 0.5 | 1.08 | 2 | 9 | 100 | 32 | 71 | 14 | |

| Spidex 280-165-B | 291 | 165 | 80 | 2 | 0.99 | 2.67 | 3 | 11 | 90 | 36 | 87 | 11.5 | |

| Spidex 280-165+B | 291 | 165 | 80 | 2 | 1.32 | 2.67 | 3 | 11 | 90 | 36 | 87 | 11.5 | |

| Spidex 330-190-B | 341 | 192 | 99 | 3 | 2.07 | 4.5 | 3 | 12 | 100 | 49 | 105 | 9.5 | |

| Spidex 330-190+B | 341 | 192 | 99 | 3 | 2.82 | 4.5 | 3 | 12 | 100 | 49 | 105 | 9.5 |

** Bucket spacing for free flowing granular products only.

* Fixing holes GB380-165 -- alternative hole punching available: slotted for 101mm to 104mm holes.

***Fixing holes GB380-165, hole centres 76-127-76mm

Note: Spidex 100-90, 130-110 and 180-140 buckets have flat holes with notched back.

With the GB system, buckets are centered at very close spacing with a series of buckets without bottoms followed by a closed bottom bucket. The material is lifted in a continuous column, so the carrying space between conventional buckets is fully utilized by material to achieve much greater capacity. The buckets "fan out" as they pass over the head and tail pulleys to facilitate pick up or discharge.

With the GB system, buckets are centered at very close spacing with a series of buckets without bottoms followed by a closed bottom bucket. The material is lifted in a continuous column, so the carrying space between conventional buckets is fully utilized by material to achieve much greater capacity. The buckets "fan out" as they pass over the head and tail pulleys to facilitate pick up or discharge.