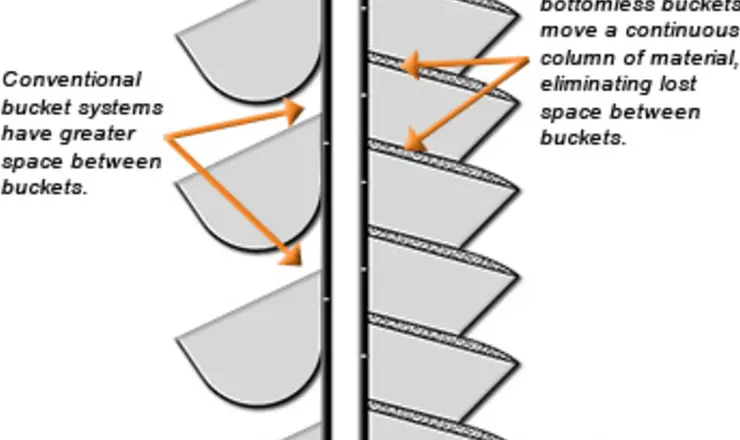

- Capacidade maxima otimizada nas pernas do elevador

- Caçambas ficam separadas por menos espaço e produto se emplilha numa coluna continua

- Serie de caçambas sem-fundo eh seguida por uma mesma com fundo

- Auto lavagem – ideal para materiais pegajosos

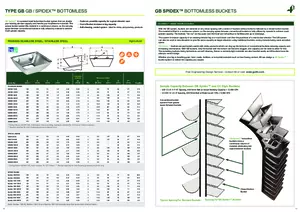

Specifications

| GB bucket | A | B | C | T | Weight | Capacity (L) | Holes | E | F | G | Bucket Spacing | Max. | |

| STANDARD | (mm) | (mm) | (mm) | (mm) | (kg) | Z2 (total) | No. | (dia mm) | (mm) | (mm) | (mm) | Pcs/Mtr | |

| GB130-110-B | 136 | 114 | 51 | 1.5 | 0.3 | 0.5 | 2 | 8.5 | 70 | 22 | 57 | 17.5 | |

| GB130-110+B | 136 | 114 | 51 | 1.5 | 0.36 | 0.5 | 2 | 8.5 | 70 | 22 | 57 | 17.5 | |

| GB180-140-B | 185 | 139 | 65 | 1.5 | 0.45 | 1.18 | 2 | 9 | 100 | 32 | 71 | 14 | |

| GB180-140+B | 185 | 139 | 65 | 1.5 | 0.55 | 1.18 | 2 | 9 | 100 | 32 | 71 | 14 | |

| GB230-165-B | 237 | 163 | 71 | 2 | 0.83 | 2.1 | 2 | 10 | 120 | 32 | 80 | 12.5 | |

| GB230-165+B | 237 | 163 | 71 | 2 | 1.12 | 2.1 | 2 | 10 | 120 | 32 | 80 | 12.5 | |

| GB300-165-B | 305 | 166 | 80 | 2 | 1.1 | 2.75 | 3 | 10.5 | 90* | 36 | 88 | 11.4 | |

| GB300-165+B | 305 | 166 | 80 | 2 | 1.4 | 2.75 | 3 | 10.5 | 90* | 36 | 88 | 11.4 | |

| GB350-200-B | 355 | 200 | 100 | 2.5 | 1.95 | 4.75 | 4 | 11 | 90 | 42 | 111 | 9 | |

| GB350-200+B | 355 | 200 | 100 | 2.5 | 2.5 | 4.75 | 4 | 11 | 90 | 42 | 111 | 9 | |

| GB400-220-B | 410 | 218 | 115 | 3 | 2.3 | 6.91 | 4 | 11 | 100 | 45 | 125 | 8 | |

| GB400-220+B | 410 | 218 | 115 | 3 | 2.95 | 6.91 | 4 | 11 | 100 | 45 | 125 | 8 |

| GB bucket | A | B | C | T | Weight | Capacity (L) | Holes | E | F | G | Bucket Spacing | Max. | |

| SPECIAL RANGE | (mm) | (mm) | (mm) | (mm) | (kg) | Z2 (total) | No. | (dia mm) | (mm) | (mm) | (mm) | Pcs/Mtr | |

| GB215-95-B | 220 | 93 | 63 | 1.5 | 0.4 | 0.95 | 2 | 8.5 | 127 | 25 | 67 | 14.9 | |

| GB215-95+B | 220 | 93 | 63 | 1.5 | 0.5 | 0.95 | 2 | 8.5 | 127 | 25 | 67 | 14.9 | |

| GB380-165-B | 380 | 165 | 80 | 2.5 | 1.7 | 3.5 | 4 | 9 | *** | 36 | 88 | 11.4 | |

| GB380-165+B | 380 | 165 | 80 | 2.5 | 2.15 | 3.5 | 4 | 9 | *** | 36 | 88 | 11.4 | |

| GB325-190-B | 335 | 191 | 88 | 2.5 | 1.65 | 3.6 | 3 | 9 | 100 | 25 | 100 | 10.5 | |

| GB325-190+B | 335 | 191 | 88 | 2.5 | 2.11 | 3.6 | 3 | 9 | 100 | 25 | 100 | 10.5 | |

| GB400-200-B | 410 | 200 | 97 | 2 | 1.66 | 5.4 | 4 | 9 | 94 | 32 | 105 | 9.5 | |

| GB400-200+B | 410 | 200 | 97 | 2 | 2.2 | 5.4 | 4 | 9 | 94 | 32 | 105 | 9.5 | |

| GB430-200-B | 437 | 200 | 95 | 2 | 1.77 | 5.56 | 4 | 9 | 94 | 32 | 105 | 9.5 | |

| GB430-200+B | 437 | 200 | 95 | 2 | 2.3 | 5.56 | 4 | 9 | 94 | 32 | 105 | 9.5 |

| SPIDEX bucket | A | B | C | T | Weight | Capacity (L) | Holes | E | F | G | Bucket Spacing | Max. | |

| (mm) | (mm) | (mm) | (mm) | (kg) | Z2 (total) | No. | (dia mm) | (mm) | (mm) | (mm) | Pcs/Mtr | ||

| Spidex 100-90-B | 106 | 88 | 45 | 0.9 | 0.1 | 0.23 | 2 | 8.5 | 50 | 17 | 50 | 20 | |

| Spidex 100-90+B | 106 | 88 | 45 | 0.9 | 0.12 | 0.23 | 2 | 8.5 | 50 | 17 | 50 | 20 | |

| Spidex 130-110-B | 136 | 114 | 51 | 1.5 | 0.26 | 0.5 | 2 | 8.5 | 70 | 22 | 57 | 17.5 | |

| Spidex 130-110+B | 136 | 114 | 51 | 1.5 | 0.31 | 0.5 | 2 | 8.5 | 70 | 22 | 57 | 17.5 | |

| Spidex 180-140-B | 185 | 139 | 65 | 1.5 | 0.41 | 1.08 | 2 | 9 | 100 | 32 | 71 | 14 | |

| Spidex 180-140+B | 185 | 139 | 65 | 1.5 | 0.5 | 1.08 | 2 | 9 | 100 | 32 | 71 | 14 | |

| Spidex 280-165-B | 291 | 165 | 80 | 2 | 0.99 | 2.67 | 3 | 11 | 90 | 36 | 87 | 11.5 | |

| Spidex 280-165+B | 291 | 165 | 80 | 2 | 1.32 | 2.67 | 3 | 11 | 90 | 36 | 87 | 11.5 | |

| Spidex 330-190-B | 341 | 192 | 99 | 3 | 2.07 | 4.5 | 3 | 12 | 100 | 49 | 105 | 9.5 | |

| Spidex 330-190+B | 341 | 192 | 99 | 3 | 2.82 | 4.5 | 3 | 12 | 100 | 49 | 105 | 9.5 |

** Bucket spacing for free flowing granular products only.

* Fixing holes GB380-165 -- alternative hole punching available: slotted for 101mm to 104mm holes.

***Fixing holes GB380-165, hole centres 76-127-76mm

Note: Spidex 100-90, 130-110 and 180-140 buckets have flat holes with notched back.

Downloads

Features

With the GB system, buckets are centered at very close spacing with a series of buckets without bottoms followed by a closed bottom bucket. The material is lifted in a continuous column, so the carrying space between conventional buckets is fully utilized by material to achieve much greater capacity. The buckets "fan out" as they pass over the head and tail pulleys to facilitate pick up or discharge.

With the GB system, buckets are centered at very close spacing with a series of buckets without bottoms followed by a closed bottom bucket. The material is lifted in a continuous column, so the carrying space between conventional buckets is fully utilized by material to achieve much greater capacity. The buckets "fan out" as they pass over the head and tail pulleys to facilitate pick up or discharge.

The system increases capacity of an existing elevator leg at a much lower cost than the purchase of a new bucket elevator. The GB system can also be used in new elevators to give the same capacity as larger elevators using traditional buckets, saving manufacturing costs and plant space.

GB Spidex™ buckets are particularly useful with sticky products which can clog up the bottoms of conventional buckets reducing capacity and increasing maintenance. With GB buckets, only the bucket with the bottom can become clogged, and capacity can be rated to allow for this. The remaining buckets, being bottomless, are self cleaning. Aeriable products are also handled easily as GB buckets have the ultimate vented design.

Whether your leg is handling grain, feed, meals, fertilizer, or industrial materials such as free flowing cement, 4B can design a GB Spidex™ bucket system to deliver the capacity you require.

Sample Capacity Between GB Spidex™ and CC Style Buckets:

• GB 12 x 6: 3-7/16" Spacing, 630 ft/min Belt at Actual Working Capacity = 12,600 CFH

• CC-HD 12 x 6: 8" Spacing, 630 ft/min Belt at Water Level +10% = 6,694 CFH

FAQ's

FAQ - Elevator Buckets

O que é uma caçamba para elevador HIGH EFFICIENCY?

As caçambas para elevadores HIGH EFFICIENCY incorporam as cinco seguintes características: frente interior suave sem “quebras”, paredes laterais sem alas, colocação vertical rente na correia do elevador, base afilada e a capacidade de empilhamento para o transporte e armazenamento. Para obter mais informações, CLIQUE AQUI

Porquê usar caçambas para elevador de perfil baixo?

As caçambas para elevador de perfil baixo foram projetadas para alcançar o espaçamento vertical mais rente possível na correia do elevador, otimizando assim o sistema e obtendo a maior capacidade potencial. Alguns estilos de caçamba para elevador exigem modificações e outros são de perfil baixo de fábrica. O material húmido ou lento não costuma carregar nem descarregar bem em caçambas para elevador de perfil baixo. Devido à capacidade adicional geral e ao peso das caçambas adicionais e do material, poderá ser necessário fazer um upgrade da força de tração nominal PIW da correia, dos diâmetros de veio da polia e dos cv do motor. Consulte o departamento de engenharia da 4B relativamente à melhor forma de obter a maior capacidade da perna do seu elevador.

Porquê perfurar buracos de ventilação na base de uma caçamba para elevador?

Ao elevar materiais esponjosos ou em pó, os buracos de ventilação na base das caçambas possibilitam um enchimento e descarga mais eficientes. Ao entrar na caçamba, o material depara-se com uma almofada de ar no fundo. Os buracos de ventilação constituem um via de escape para esta almofada de ar, para que o material introduzido não salte da caçamba e desça pela estrutura da perna do elevador. Na descarga, os buracos de ventilação permitem a entrada de ar na caçamba à medida que o material sai, libertando o vácuo que poderia provocar a permanência na estrutura.

As caçambas para elevador de estilo CC são intercambiáveis com as caçambas Starco?

As caçambas para elevador Starco apresentam uma geometria pouco profunda e destinam-se à colocação muito juntas na correia do elevador. Assim sendo, deverá consultar o departamento de engenharia da 4B acerca da troca de caçambas Starco por outra marca ou design.

De que comprimento de parafuso de elevador preciso?

Ao instalar caçambas numa correia de elevador, aplique esta fórmula simples:

(espessura da correia + espessura da traseira da caçamba + espessura da anilha + espessura da porca + 6,35 mm)

O que é uma caçamba “escavadora”?

Alguns materiais podem formar uma crosta endurecida na parede lateral da bota do elevador e os pós acumulados podem tornar-se rígidos. Estas duas situações podem causar o desgaste prematuro da caçamba. As caçambas escavadoras são concebidas com ligeiramente mais largura e projeção do que as caçambas padrão e, assim, “escavam” ou partem o material endurecido, ajudando a prevenir o desgaste adicional das caçambas padrão. As caçambas escavadoras são normalmente feitas de aço. Contudo, caçambas de nylon também podem ser utilizadas conforme a aplicação.

De quantas caçambas escavadoras preciso?

Para a maioria das aplicações, utilize uma caçamba escavadora por cada nove caçambas padrão.

Posso utilizar caçambas numa emenda sobreposta?

As emendas sobrepostas duplicam a espessura da correia, pelo que a projeção da caçamba aumenta na sobreposição. Normalmente, isto não causa um problema, mas se o fizer, pode utilizar caçambas com menos 2,5 cm de projeção ou cortar a ponta de cada caçamba em 1,27 cm na zona emendada.

Ao utilizar uma emenda sobreposta, quanta correia extra deveria usar para a emenda?

O comprimento da emenda deverá ser três vezes a largura da correia.

Com que frequência devo trocar a borracha da polia principal?

A borracha deverá ser trocada sempre que a correia do elevador for substituída.

Design Services

Desenho técnico de elevadores de caçambas

Desenho técnico de elevadores de caçambas

A 4B desenhou centenas de elevadores de caçambas para todas as indústrias, incluindo rações para animais, manuseamento de grãos, moagem de farinha, maltagem e fabricação de cerveja, cimento, carvão e outras indústrias pesadas.

Aproveite o serviço de assistência técnica mundial, garantido e sem custos da 4B e beneficie dos conhecimentos de uma equipa de engenheiros especializados no design e cálculo de elevadores de caçambas. Com base nos seus dados técnicos mais importantes, os nossos engenheiros podem fazer uma recomendação técnica detalhada para o elevador de balde certo, com as caraterísticas de capacidade e descarga ideais. Podemos desenhar um novo elevador ou ajudá-lo a aumentar a capacidade do seu atual elevador.

Obter um cálculo de elevador de caçambas gratuito

Preencha este formulário da forma mais precisa possível para que a sua consulta seja atendida de forma mais eficaz.

A 4B desenhou centenas de elevadores de caçambas para todas as indústrias, incluindo rações para animais, manuseamento de grãos, moagem de farinha, maltagem e fabricação de cerveja, cimento, carvão e outras indústrias pesadas.

Aproveite o serviço de assistência técnica mundial, garantido e sem custos da 4B e beneficie dos conhecimentos de uma equipa de engenheiros especializados no design e cálculo de elevadores de caçambas. Com base nos seus dados técnicos mais importantes, os nossos engenheiros podem fazer uma recomendação técnica detalhada para o elevador de balde certo, com as caraterísticas de capacidade e descarga ideais. Podemos desenhar um novo elevador ou ajudá-lo a aumentar a capacidade do seu atual elevador.

Obter um cálculo de elevador de caçambas gratuito

Preencha este formulário da forma mais precisa possível para que a sua consulta seja atendida de forma mais eficaz.