The 4B heavy duty aluminium Rotech rotary shaft encoder is used primarily for protecting equipment and personnel from dangerous underspeed/belt slip conditions in extreme environments. Other applications include accurate speed control, direction of rotation detection, gate position indication and counting the number of revolutions of the shaft.

An inductive sensing device in the body of the encoder detects a steel rotor. On slow speed or accurate position control, a photo diode detects the slots on a steel disk. One pulse is created for each rotor or slot so the unit can be connected directly to a PLC/computer or 4B control module.

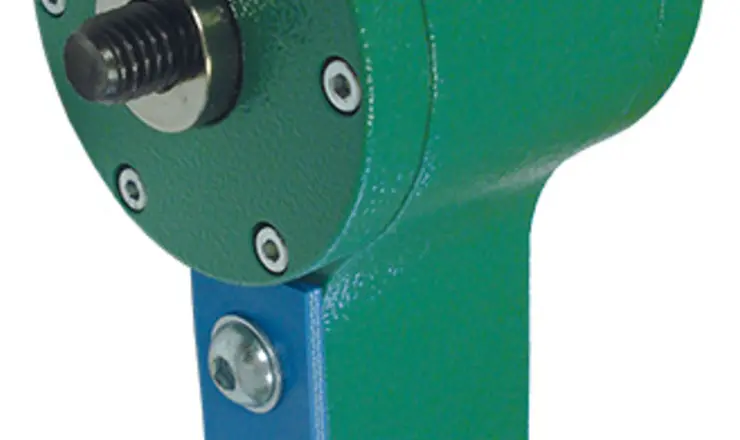

The shaft to be monitored is drilled and taped to take the 1/2 in. UNC Rotech Bolt. The unit is secured to the shaft with this bolt and is able to move with the shaft. No guards are required as the rotating components are encased inside the housing of the encoder. No brackets are required as the encoder couples directly to the end of the shaft and floats with the shaft.

- Rotating shaft monitor

- Aluminium housing

- Provides information on shaft speed, direction, position or revolution

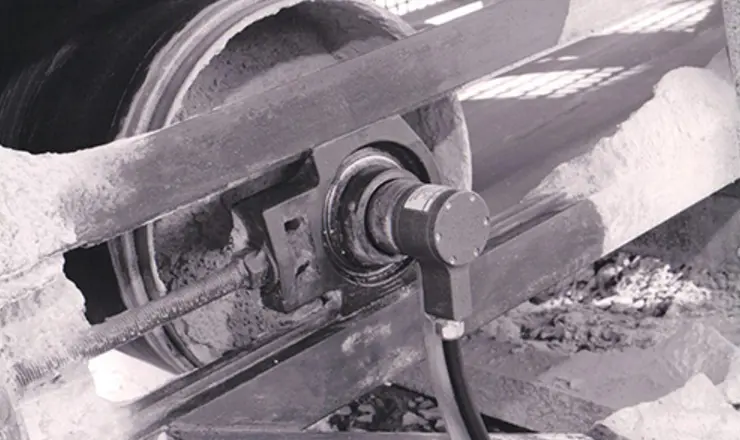

- For conveyors, elevators, mixers, fans, pumps, grinders & other mechanical handling systems

- Heavy duty versions - suitable for the most severe industrial environments, IP65

- Compatible with the "Magcon" quick-connect device

Downloads

FAQ's

The shaft is turning, but there is no signal coming from the sensor. What is the problem?

The bolt connecting the encoder to the shaft is not tight. Remove the back plate and tighten down the connecting bolt with a hex key (Allen wrench). Note: the hex key will be under a plastic cap, be sure to replace this cap before reassembling the back plate on the encoder.