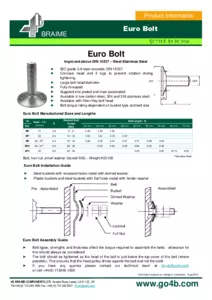

EURO-pultti (n. DIN 15237)

Product Features

- teräs / ruostumaton teräs 304 & 316

- n. DIN 15237

- min. pintakovuus 90-95 Rockwell B

- ISO-luokka 5.8 (ylittää DIN)

- läpimitaltaan iso pulttikanta

- vakiona täysin kierteinen ja sinkitty, tai ruostumaton

Bolt Material

Stainless Steel

Steel (self colour)

Steel (zinc plated)

Specifications

| Euro | Size | Head Diameter | Max. Torque | Package Quantity | Package Weight |

| bolts | (mm) | (mm) | (Nm) | (kg) | |

| M6 x 20 | 21 | 8 | 100 | 1.28 | |

| M6 x 25 | 21 | 8 | 100 | 1.38 | |

| M6 x 30 | 21 | 8 | 100 | 1.5 | |

| M7 x 20 | 23 | 13 | 100 | 1.82 | |

| M7 x 22 | 23 | 13 | 100 | 1.94 | |

| M7 x 25 | 23 | 13 | 100 | 2.1 | |

| M7 x 30 | 23 | 13 | 100 | 2.16 | |

| M7 x 35 | 23 | 13 | 100 | 2.22 | |

| M8 x 20 | 28 | 25*** | 20 | 100 | 2.98 | |

| M8 x 22 | 28 | 25*** | 20 | 100 | 2 | |

| M8 x 25 | 28 | 25*** | 20 | 100 | 3 | |

| M8 x 30 | 28 | 25*** | 20 | 100 | 3.02 | |

| M8 x 35 | 28 | 25*** | 20 | 100 | 3.37 | |

| M8 x 40 | 28 | 25*** | 20 | 100 | 3.72 | |

| M8 x 45 | 28 | 25*** | 20 | 100 | 3.88 | |

| M8 x 50 | 28 | 25*** | 20 | 100 | 3.94 | |

| M10 x 25 | 35 | 31*** | 36 | 100 | 5.42 | |

| M10 x 30 | 35| 31*** | 36 | 100 | 5.43 | |

| M10 x 35 | 35 | 31*** | 36 | 100 | 5.44 | |

| M10 x 40 | 35 | 31*** | 36 | 100 | 5.84 | |

| M10 x 45 | 35 | 31*** | 36 | 100 | 6.02 | |

| M10 x 50 | 35 | 31*** | 36 | 100 | 6.18 | |

| M12 x 40* | 42 | 65 | 100 | 9.24 | |

| M12 x 50* | 42 | 65 | 100 | 4.96** | |

| M12 x 60* | 42 | 65 | 100 | 5.36** | |

| M12 x 70* | 42 | 65 | 100 | 5.60** |

* Not available in stainless steel.