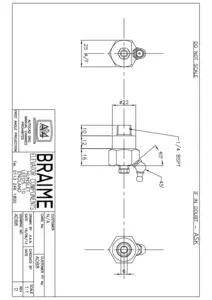

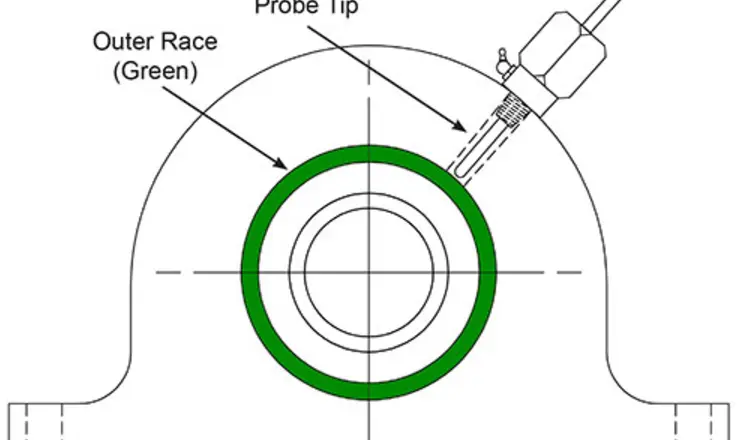

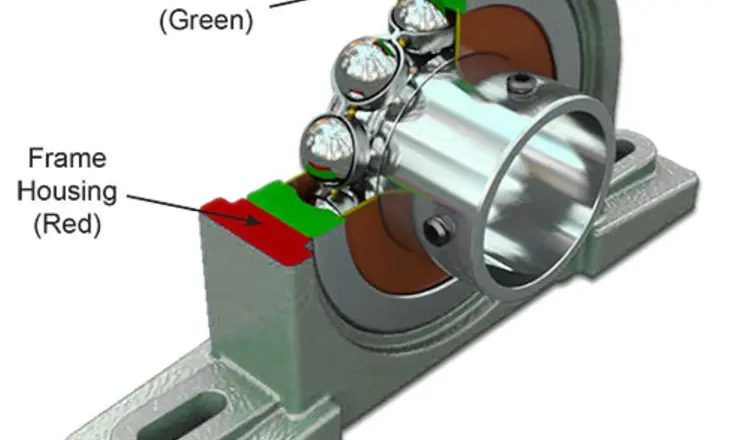

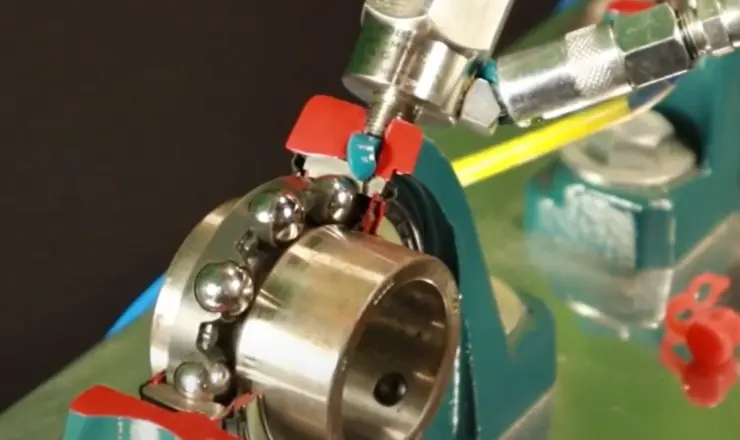

The ADB series have been designed to allow the depth of the sensor to be adjustable depending on your application. A number of versions are available with probe lengths of 50, 100, 200 and 300 mm. The sensors screw directly into a bearing housing through a 1/4” BSPT threaded grease zerk. Each sensor is fitted with a grease zerk to allow lubrication of the bearing without the need for removal of the sensor. The ADB series have NTC or PT100 type thermistors which allow for continuous temperature monitoring.

The sensor is supplied with a 3m attached cable and can be connected to a PLC or to a hazard monitoring system, such as 4B’s Watchdog Super Elite, T500 Hotbus Elite or T400 NTC Elite. The connections are not polarity sensitive therefore special connection requirements are eliminated, and the cable can be extended in the field.

- Screw in positive mount installation

- Grease zerk for bearing lubrication

- Adjustable depth probes (50, 100, 200 & 300mm)

- ADB81 - 1/4" BSPT mounting thread with cable entry

- ADB2 - 1/8'' NPT mounting thread with conduit entry

- NTC or PT100 thermistor - continuous temperature monitoring

Belt Conveyor

Bucket Elevator

Chain Conveyor

Screw Conveyor

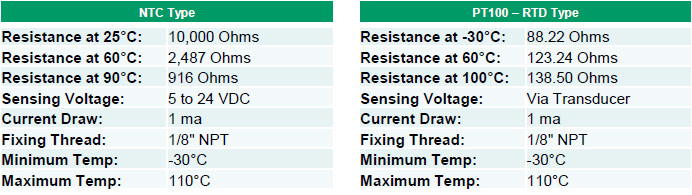

Specifications

| | Part Number | Description | Thermistor Type | Thread | ATEX Zone | IECEx |

| . | ||||||

| ADB810V3AI/D2 | 3m Cable; 50mm Probe | NTC | ¼” BSPT | 20 | Y | |

| ADB810V3AI/D4 | 3m Cable; 100mm Probe | NTC | ¼” BSPT | 20 | Y | |

| ADB810V3AI/D8 | 3m Cable; 200mm Probe | NTC | ¼” BSPT | 20 | Y | |

| ADB810V3AI/D12 | 3m Cable; 300mm Probe | NTC | ¼” BSPT | 20 | Y | |

| ADB819V3AI/D2 | 3m Cable; 50mm Probe | PT100 | ¼” BSPT | 20 | Y | |

| ADB819V3AI/D4 | 3m Cable; 100mm Probe | PT100 | ¼” BSPT | 20 | Y | |

| ADB819V3AI/D8 | 3m Cable; 200mm Probe | PT100 | ¼” BSPT | 20 | Y | |

| ADB819V3AI/D12 | 3m Cable; 300mm Probe | PT100 | ¼” BSPT | 20 | Y |

| Part Number | Description | Thermistor Type | Thread | CSA | ATEX | ICECx | |

| . | |||||||

| ADB20V3CAI/D2 | 3m Cable; 50mm Probe | NTC | 1/8” NPT | Class II Div 1 | Zone 20 | Zone 20 | |

| ADB20V3CAI/D4 | 3m Cable; 100mm Probe | NTC | 1/8” NPT | Class II Div 1 | Zone 20 | Zone 20 | |

| ADB20V3CAI/D8 | 3m Cable; 200mm Probe | NTC | 1/8” NPT | Class II Div 1 | Zone 20 | Zone 20 | |

| ADB20V3CAI/D12 | 3m Cable; 300mm Probe | NTC | 1/8” NPT | Class II Div 1 | Zone 20 | Zone 20 | |

| ADB29V3CAI/D2 | 3m Cable; 50mm Probe | PT100 | 1/8” NPT | Class II Div 1 | Zone 20 | Zone 20 | |

| ADB29V3CAI/D4 | 3m Cable; 100mm Probe | PT100 | 1/8” NPT | Class II Div 1 | Zone 20 | Zone 20 | |

| ADB29V3CAI/D8 | 3m Cable; 200mm Probe | PT100 | 1/8” NPT | Class II Div 1 | Zone 20 | Zone 20 | |

| ADB29V3CAI/D12 | 3m Cable; 300mm Probe | PT100 | 1/8” NPT | Class II Div 1 | Zone 20 | Zone 20 | |

| ADBW | Probe Depth Adjustment Tool | - | - | - | - | - |

Note: 5m Cable Sensors are Available on Request

ADB810V3AI has now been changed to ADB810V3AI/D4.

ADB819V3AI has now been changed to ADB819V3AI/D4.