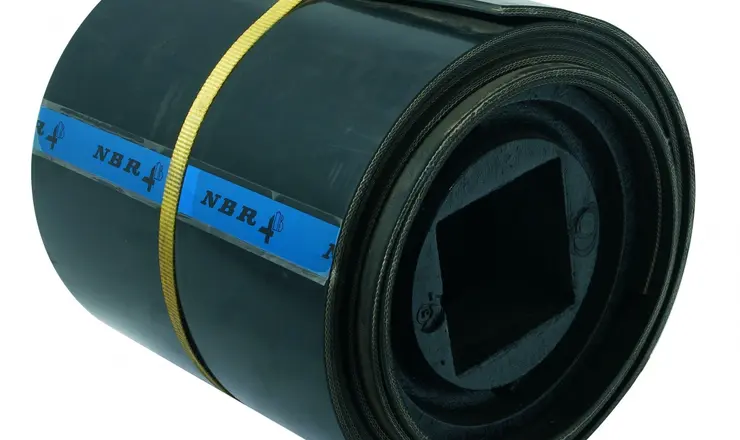

NBR Nitrile provides good resistance to oil and fat. Suitable for products containing oils and fat up to 100˚C.

- For materials with oil & fat

- Excellent strength & bolt holding

- 100% Nitrile rubber with niltrile interplies

- Maximum oil resistance to animal & vegetable oils

- Moisture resistant - no belt rot

- Belt types: EP500/3, EP630/4, EP800/4, EP1000/5, EP1250/5, EP1600/5

Specifications

| Type | EP500/3 | EP630/4 | EP800/4 | EP1000/5 | EP1250/5 | EP1600/5 | ||

| NBR | 1+1 NBR | 1.5+1.5 NBR | 2+2 NBR | 2+2 NBR | 2+2 NBR | 2+2 NBR | ||

| Strength per ply | kN/m | 160 | 160 | 200 | 200 | 250 | 315 | |

| Number of plies | 3 | 4 | 4 | 5 | 5 | 5 | ||

| Total tensile strength | kN/m | 500 | 630 | 800 | 1000 | 1250 | 1600 | |

| Maximum working tension | kN/m | 50 | 63 | 80 | 100 | 125 | 160 | |

| Top & bottom cover thickness | mm | 1 | 1.5 | 2 | 2 | 2 | 2 | |

| Belt thickness | mm | 6 | 8 | 9.5 | 11 | 12.5 | 13.5 | |

| Weight | kg/sqm | 7.6 | 10.2 | 12 | 13.9 | 15.6 | 17.5 | |

| Minimum pulley diameter | mm | 315 | 500 | 500 | 800 | 800 | 1000 |

Technical Specifications:

- Applications: For products containing oils and fats up to 100°C

- Covers: NBR 100% Nitrile Butadiene Synthetic Rubber

- Carcass: Polyester fabric warp and polyamide fabric weft plies (EP) separated by 0.3mm thick synthetic rubber laminates of 100% Nitrile

- Temperature Range: -25°C to +100°C

- Standard: Manufactured to BS 490, DIN 22102 and DIN 22104 standard

Downloads

Accessories

Gripwell Elevator Belt Splices

The Gripwell light duty aluminum fastener secures belting on bucket elevators. The two ends of the belt are gripped between extruded serrated plates, clamped together by zinc plated high tensile bolts, safely secured by plated self locking nuts to give a strong reliable and rustproof fastener. The Gripwell forms a butt joint, the belt runs smoothly over the pulley with minimum stress to the joint and no relative movement can take place between the two belt ends, as is the case when an overlapping joint passes over the pulleys.

Supergrip Elevator Belt Splices

The Supergrip heavy duty belt fastener secures belting on bucket elevators. The two ends of the belt are gripped between extruded steel plates, clamped together by zinc plated high tensile bolts and self-locking nuts.

4B Vise Splice

4B Vise Splices are mechanical splices and fasteners for use on most PVC and rubber elevator belts.

Each splice unit is made of three pieces. The outside plates have two different gripping areas. The ribbed gripping area is mounted towards the face of the belt. The opposite end has a series of both longitudinal and axial "teeth." The center plate is symmetrical and cannot be improperly installed around its elongated center hole.

The splice works by using the tension supplied by the belting. This tension on the belt ends pulls the outer plates apart, and forces gripping pressure towards the teeth on the splice unit. The greater the belt tension, the more pressure is exerted on the gripping teeth at the forward end of the splice.

Design Services

Bucket Elevator Design Service

Bucket Elevator Design Service

At 4B, we have designed hundreds of bucket elevators for all industries, including Animal Feed, Grain Handling, Flour Milling, Malting & Brewing through to Cement, Coal and other heavy industries.

Take advantage of 4B's free, guaranteed worldwide technical support service from a team of engineers specialising in the design and calculation of bucket elevators.. Using your key technical data, our engineers can give you a detailed technical recommendation for the ideal bucket elevator with the ideal capacity and discharge characteristics. We can either design your new bucket elevator or we can help you to increase the capacity of your existing bucket elevator.

To get a free bucket elevator calculation

Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.

At 4B, we have designed hundreds of bucket elevators for all industries, including Animal Feed, Grain Handling, Flour Milling, Malting & Brewing through to Cement, Coal and other heavy industries.

Take advantage of 4B's free, guaranteed worldwide technical support service from a team of engineers specialising in the design and calculation of bucket elevators.. Using your key technical data, our engineers can give you a detailed technical recommendation for the ideal bucket elevator with the ideal capacity and discharge characteristics. We can either design your new bucket elevator or we can help you to increase the capacity of your existing bucket elevator.

To get a free bucket elevator calculation

Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.