Ray-Carroll County Grain Growers needed to increase receiving capacity without shutting down operations. 4B offered a solution using JCC-S low profile elevator buckets allowing closer installation and the addition of 224 buckets per leg. - A 75% capacity increase!

Ray-Carroll County Grain Growers, 2.8-million bushel country elevator in Carrollton, MO needed to increase receiving capacity in order to better accommodate its growing customer base. The challenge was to upgrade the receiving system without shutting down operations. Twenty million bushels of corn are received at this facility every year.

Ray-Carroll County Grain Growers, 2.8-million bushel country elevator in Carrollton, MO needed to increase receiving capacity in order to better accommodate its growing customer base. The challenge was to upgrade the receiving system without shutting down operations. Twenty million bushels of corn are received at this facility every year.

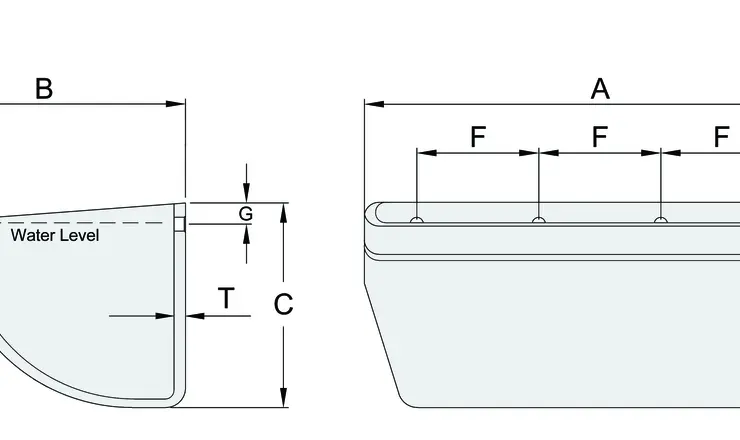

4B Components engineering group analyzed the existing elevator legs and designed an improved solution. 4B JUMBO™ CC-S ® 16x8 low-profile buckets were installed and spaced 7.75 inches apart. The low-profile design allowed Ray-Carroll to install the buckets closer together resulting in the ability to add 224 additional buckets per leg. To handle the increased load of the additional buckets, 18 inch wide 1,000-PIW (pounds per inch of belt width) rubber belting was installed utilizing 4B BC belt splice clamps, designed for heavy weight elevator belts.

4B Components engineering group analyzed the existing elevator legs and designed an improved solution. 4B JUMBO™ CC-S ® 16x8 low-profile buckets were installed and spaced 7.75 inches apart. The low-profile design allowed Ray-Carroll to install the buckets closer together resulting in the ability to add 224 additional buckets per leg. To handle the increased load of the additional buckets, 18 inch wide 1,000-PIW (pounds per inch of belt width) rubber belting was installed utilizing 4B BC belt splice clamps, designed for heavy weight elevator belts.

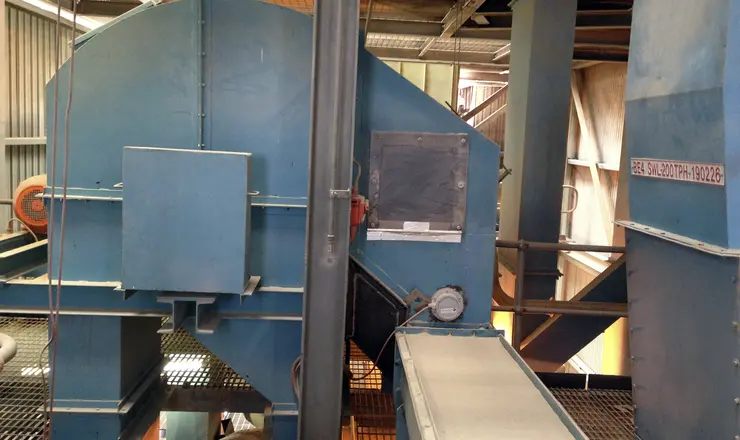

It took two days for the millwright team to install the new buckets on the two elevator legs. By working on one leg at a time, the other remained operational, and the elevator was able to receive grain throughout the process. Before the upgrades, the two legs each ran at 8,500 bph capacity. Now, each leg can handle 15,000 bph, an increase of approximately 75% throughput.

Ray-Carroll was very pleased with the solution provided by the 4B engineering team. They increased capacity and by the installation of the 4B JUMBO™ CC-S ® 16x8 low profile buckets they achieved their goal of making it easier and quicker for their customers to deliver grain. Trucks now go scale to scale in under four minutes.

It took two days for the millwright team to install the new buckets on the two elevator legs. By working on one leg at a time, the other remained operational, and the elevator was able to receive grain throughout the process. Before the upgrades, the two legs each ran at 8,500 bph capacity. Now, each leg can handle 15,000 bph, an increase of approximately 75% throughput.

Ray-Carroll was very pleased with the solution provided by the 4B engineering team. They increased capacity and by the installation of the 4B JUMBO™ CC-S ® 16x8 low profile buckets they achieved their goal of making it easier and quicker for their customers to deliver grain. Trucks now go scale to scale in under four minutes.