Multi-Location Grain Cooperative in the US. Existing stand-alone systems upgraded to fully integrated monitoring solution, using Industrial Ethernet Nodes for remote sensor connectivity; Hazardmon.com for cloud monitoring; and testing tools for 100% verifiability of equipment.

A large, Midwestern grain and feed cooperative grew considerably through organic growth, mergers, and acquisitions. The cooperative management team initiated an operational improvement plan and was also keen on upgrading the company’s hazard monitoring to increase the company’s safety, up-time, and reliability. The company had a multitude of facilities from small to large; old to new; feed, grain, milling, and fertilizer all with varying levels of automation and monitoring needs. The company’s 60-plus facilities are hundreds of miles apart, so reliability, operational testability, remote access, and support were key requirements. The challenge for the company was to find a single vendor that could meet all of these requirements.

A large, Midwestern grain and feed cooperative grew considerably through organic growth, mergers, and acquisitions. The cooperative management team initiated an operational improvement plan and was also keen on upgrading the company’s hazard monitoring to increase the company’s safety, up-time, and reliability. The company had a multitude of facilities from small to large; old to new; feed, grain, milling, and fertilizer all with varying levels of automation and monitoring needs. The company’s 60-plus facilities are hundreds of miles apart, so reliability, operational testability, remote access, and support were key requirements. The challenge for the company was to find a single vendor that could meet all of these requirements.

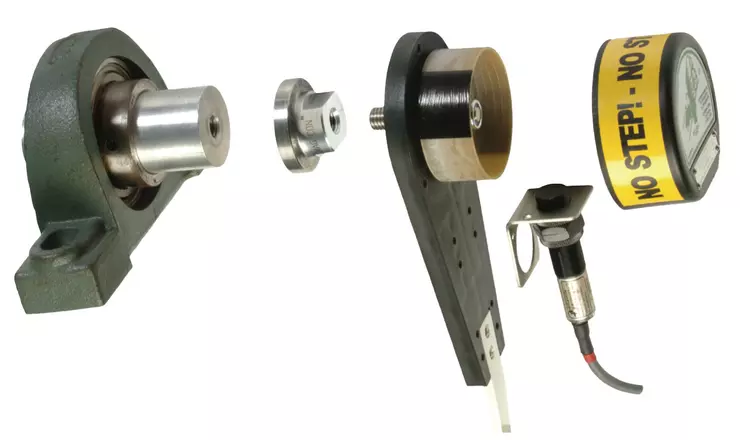

The company was using at least six different manufacturers of hazard monitoring systems in their facilities, so they had familiarity with a range of available vendors. After extensive research, consultation and analysis, the company selected 4B Components Ltd. as the vendor of choice. The innovative and high quality 4B solutions deployed were: sensors for conveyor speed, bearing temperature, belt alignment, plug condition, slack chain and gate position; Watchdog Super Elite hazard monitor controllers for local control and rapid deployment; Flex-Net System Industrial Ethernet Nodes for remote sensor connectivity; HazardMon.com for cloud monitoring; and testing tools for 100% functional testing and verifiability of sensors and controllers. In addition to providing electronic hardware, 4B toured every facility to assess existing systems and recommend upgrades to ensure successful monitoring, 4B inspected the installation and commissioned startup of the systems, and 4B provided product training to plant personnel and management.

The company was using at least six different manufacturers of hazard monitoring systems in their facilities, so they had familiarity with a range of available vendors. After extensive research, consultation and analysis, the company selected 4B Components Ltd. as the vendor of choice. The innovative and high quality 4B solutions deployed were: sensors for conveyor speed, bearing temperature, belt alignment, plug condition, slack chain and gate position; Watchdog Super Elite hazard monitor controllers for local control and rapid deployment; Flex-Net System Industrial Ethernet Nodes for remote sensor connectivity; HazardMon.com for cloud monitoring; and testing tools for 100% functional testing and verifiability of sensors and controllers. In addition to providing electronic hardware, 4B toured every facility to assess existing systems and recommend upgrades to ensure successful monitoring, 4B inspected the installation and commissioned startup of the systems, and 4B provided product training to plant personnel and management.

Once the 4B system was installed and commissioned, the benefits were immediate:

- A 4B Watchdog Super Elite system alerted operators of a belt misalignment problem on a bucket elevator. Millwrights were called in to correct the issue and found that tracking the belt was difficult due to worn lagging on the head pulley. Once the lagging was repaired, the bucket elevator belt tracked properly.

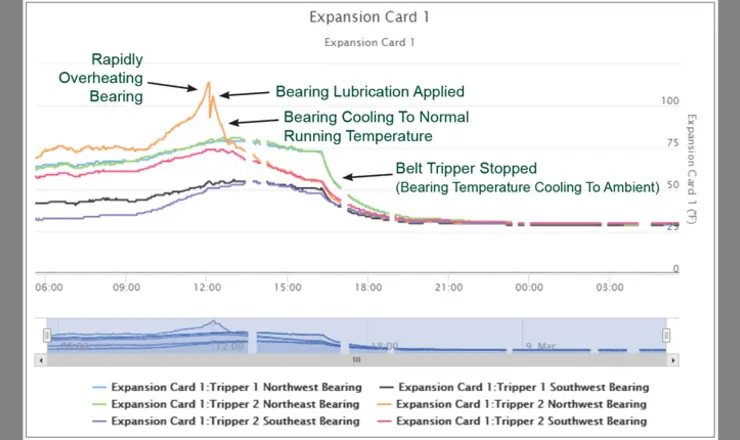

- While monitoring a facility in real-time via the cloud and HazardMon.com, supervisors noticed a rapidly overheating bearing (see online data below in orange for Tripper 2 Northwest Bearing) and immediately notified the location maintenance manager. The maintenance technician’s lubrication effects can be seen as the bearing temperature returns to normal and a potentially catastrophic failure is averted.

Once the 4B system was installed and commissioned, the benefits were immediate:

- A 4B Watchdog Super Elite system alerted operators of a belt misalignment problem on a bucket elevator. Millwrights were called in to correct the issue and found that tracking the belt was difficult due to worn lagging on the head pulley. Once the lagging was repaired, the bucket elevator belt tracked properly.

- While monitoring a facility in real-time via the cloud and HazardMon.com, supervisors noticed a rapidly overheating bearing (see online data below in orange for Tripper 2 Northwest Bearing) and immediately notified the location maintenance manager. The maintenance technician’s lubrication effects can be seen as the bearing temperature returns to normal and a potentially catastrophic failure is averted.