- Force Activated Belt and Pulley Alignment Sensor

- Instantaneous Misalignment Indication

- Hardened Stainless Steel Contact Face

- External Test Feature

- Output LED Indication

- Not a Rub Block

Alignment Sensors

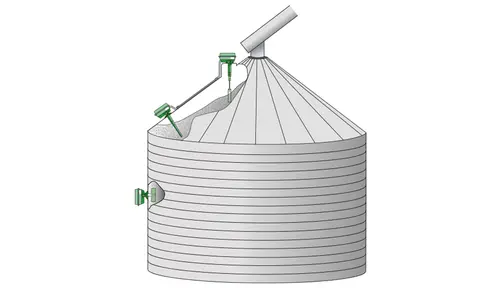

4B's line of sensors and switches are designed to detect (mis)alignment and motion on bucket elevators & belt conveyors.

4B's WDA sensor can also be used as a slack chain detector on drag chain conveyors.

View our NEW Electronics Catalogue here.

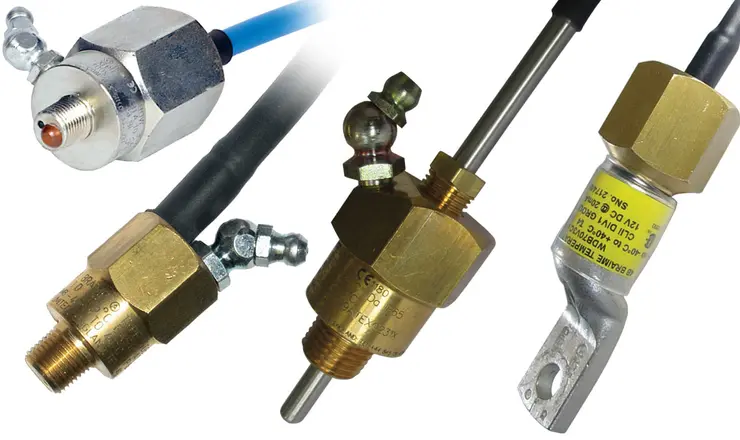

- Magnetic Proximity Belt Speed and Belt Alignment Sensor

- Adjustable Sensing Range 25mm to 75 mm

- LED Indication

- Mounting Bracket Included

- ½” NTP Conduit Entry

- Stainless Steel Construction

- High Temperature Version Available

- IP66 Protection

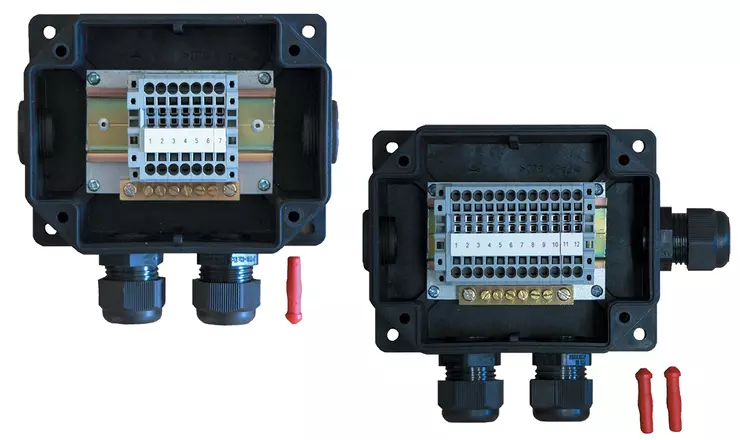

- Conveyor Belt Misalignment & Rip Detection System

- Electro-mechanical system designed to detect dangerous misalignment of the conveyor and also detection of belt tear damage

- Triggers an alarm at 20º and a shutdown of the machine at 35º

- Easy installation

- Robust design

- No calibration required

- Nylon rollers as standard; stainless steel rollers available on request

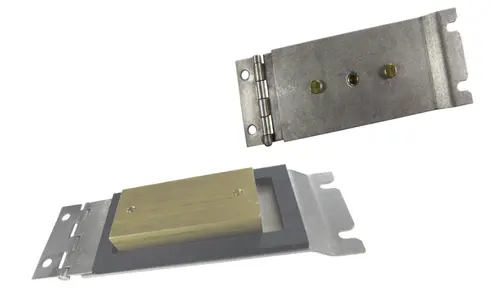

- Brass Rub Block Belt Misalignment Sensor

- Belt Misalignment Detection

- Simple Installation

- Solid Brass Construction (No Moving Parts)

- Temperature-Activated by Friction

- Applicable bearing sensors - not included in kit:

ADB91MV3AI/D2 (4-20mA), ADB20V3CAI/D2 (NTC), ADB29V3CAI/D2 (PT100) & ADBMIL1V4C/D2 (4-20mA) - External Sensor Testing Capability (ADB Tester)

- Magnetic Proximity Belt Speed and Belt Alignment Sensor

- Detects Moving Steel Ferrous Targets

- Adjustable Sensing Range of 25 – 75mm

- Not Affected by Material Build Up

- Stainless Steel Construction

- High Temperature Version Available

- Rugged housing for the most arduous environments

- Fail safe magnetic sensor immune to build up of material

- Powerful sensing range of 12 – 50mm, easily adjusted on the sensor or at the control unit

- Links direct to PLC or to independent control unit A400 Elite or Watchdog Elite