Hochleistungsbecher

At 4B, our basis has always been engineering and our expertise in providing comprehensive solutions. In keeping with these core values, we designed our family of High Efficiency elevator buckets to deliver the maximum possible elevator leg throughput for the lowest cost per ton or bushel. Every bucket in every line of the High Efficiency family has five distinct features, each of which conveys efficiency. Only 4B High Efficiency elevator buckets have all five features.

|

MODERN HIGH EFFICIENCY DESIGN

|

|

TRADITIONAL DESIGN

|

||

|

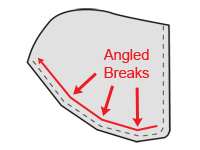

SMOOTH FRONT FACE A smooth interior face and side walls, with no “breaks”, deliver an efficient and unencumbered discharge over higher speeds. |

|

Other designs have angled “breaks” which provide no benefit to discharge efficiency. These “breaks” merely copy a feature from the first sheet metal buckets introduced in the 1920's. |

|

|

|

|

|

|||

|

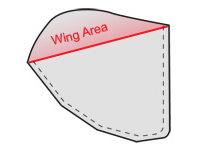

WING-LESS SIDEWALLS Wing-less side walls maximize the most efficient use and cost of materials. |

|

Other buckets have a wing or “ear” on both sides which adds cost and weight, while offering no functional benefit. |

|

|

|

|

|

|||

|

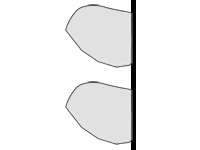

CLOSER SPACING The ability to be mounted extremely close together provides the most efficient use of vertical space on the belt. |

|

Other buckets are too deep to be mounted closely together or must be modified from their standard design, adding to the cost. |

|

|

|

|

|

|||

|

TAPERED BOTTOMS Tapered bottoms allow the buckets to fill and discharge with maximum efficiency over higher speeds. |

|

The vertical sides, wings and perpendicular bottoms of other buckets impede the flow of materials into and out of the bucket. |

|

|

|

|

|

|||

|

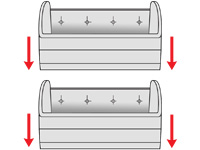

NESTING / STACKING Nesting inside one another efficiently reduces the amount of space and costs associated with shipping and storage. |

|

Nesting is not possible with other bucket designs. More packing materials and space are required for these buckets. |

|

|