电子监控设备

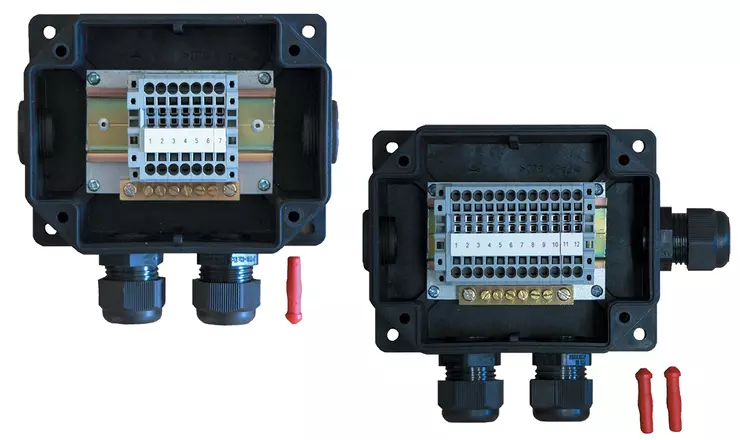

4B 向业界提供最齐备的面向斗提机、链式输送机、皮带输送机和螺旋输送机及料仓的安全监控系统和电子部件。4B 可以为您提供全方位的产品和技术服务,从简单的传感器更换到提供面完整的全监测系统解决方案。我们的系统可以独立运作,也可以同时接入您的 PLC 系统。

4B 的安全监控系统和电子部件都通过了国际主流防爆认证:ATEX / IECEx / CSA 等。4B 可为您提供包括安装、调试、培训以及售后服务在内的全方位服务。

我们的工程师团队能为您提供最佳的安全监控产品组合和整体解决方案。点击这里查看并填写“有关输送设备安全监控设计、改造和问题解决”的问卷。

电子监控设备

Bucket Elevator

The bucket elevator is one of the most efficient methods for elevating bulk granular materials - but it is also one of the most dangerous. The dust generated from the movement of materials within the elevator can be highly explosive, and mechanical failure or incorrect operation of the bucket elevator can have catastrophic consequences. The most common hazards on bucket elevators are belt misalignment, belt slippage, blocked chutes, and bearing failures, each of which should be monitored to reduce the risk of fires, explosions or breakdowns that result in costly downtime.

4b offer a range of monitoring equipment and sensors to monitor those hazards.

(Illustration shows typical sensor placements, applications may vary).

Belt Conveyor

Belt Conveyors are used in many bulk material handling applications ranging from agricultural application such as grain handling through to heavy duty applications, such as quarrying and mining. They consist of 2 or more pulleys with a continuous loop of conveyor belt that rotates around them.

4B supplies a complete range of ATEX / IECEx / CSA approved monitoring equipment for belt conveyors, designed to monitor belt conveyors for dangerous conditions and prevent costly downtimes. The range includes belt misalignment and belt rip detectors, speed switches, bearing temperature sensors, choke switches, pullwire conveyor safety stop switches and multi-functional monitoring systems for belt conveyors.

(Illustration shows typical sensor placements, applications may vary).

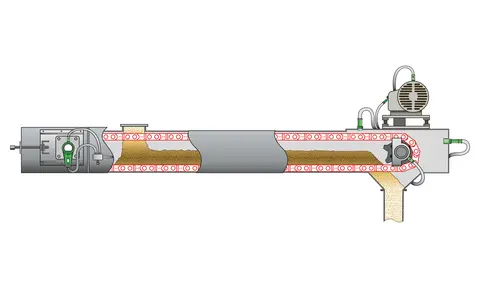

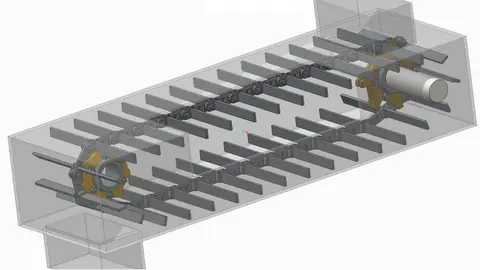

Chain Conveyor

Chain Conveyors are an essential part of many bulk handling systems, where they are used to convey bulk materials such as powders, grains, flakes and pellets.

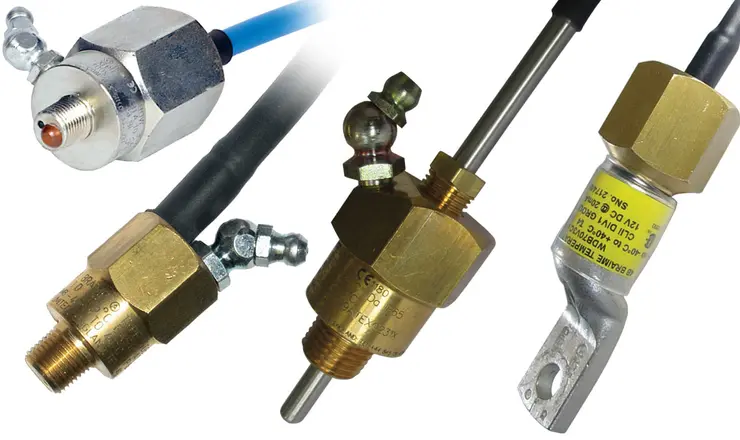

4B has a wide range of sensors for monitoring the various parts of your drag chain conveyor. The most common areas for monitoring include: bearing temperature, speed / motion, level / plug indication and slack / broken chain detection.

All of 4B's sensors can be connected to our hazard monitoring systems.

(Illustration shows typical sensor placements, applications may vary).

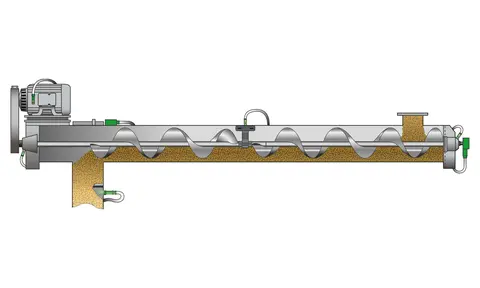

Screw Conveyor

Screw conveyors provide an enclosed method of transferring materials both horizontally and on an inclination.

4B offer a range of electronic monitoring components that can be used on screw conveyors to ensure that they operate efficiently and safely, including blockage detectors, bearing temperature monitors and rotation speed monitors. Click on the links below to view these product on the 4B website.

(Illustration shows typical sensor placements, applications may vary).

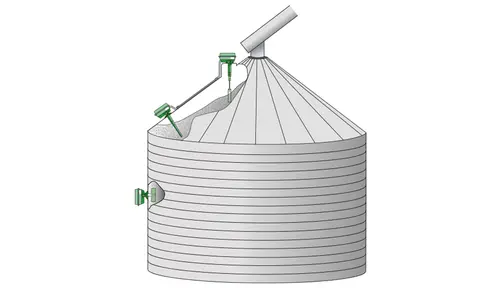

Silos & Storage

4B has a wide range of level indicators for point level indication of bulk granular solids or powders in bins and silos.

All of 4B's sensors can be connected to our hazard monitoring systems.

(Illustration shows typical sensor placements, applications may vary).