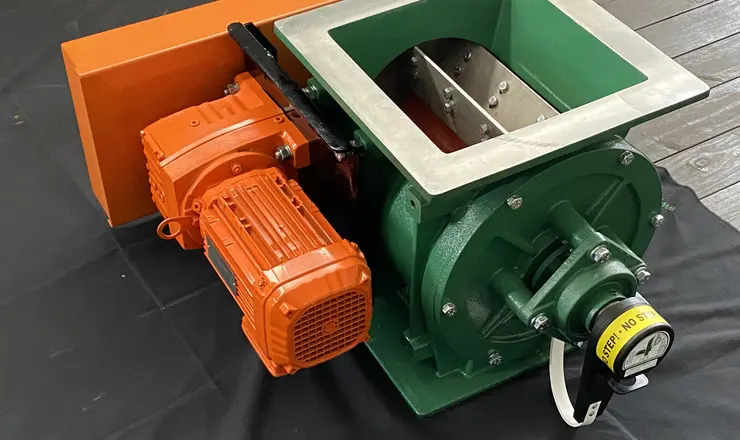

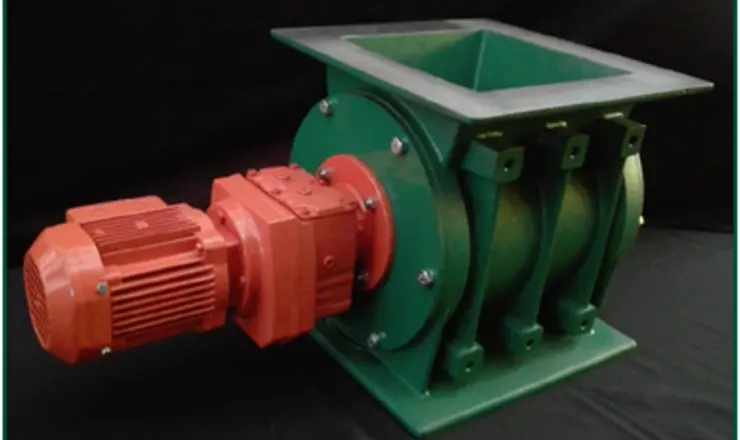

The 4B series of High Wearing Ductile Cast Iron Rotary Valves provides those involved in Bulk Material Handling a drop through metering valve that provides a constant volumetric feed rate.

Rotary Valves are the first option where there is limited space and controlled feeding is required of powders and granular materials from silos, bins and hoppers.

The Multi Vane Rotor provides accurate dosing and reduces leakage from cyclones and dust collectors in to low and medium pressure pneumatic conveying lines. The same drop through valve can be utilised in feeding in to pneumatic conveying lines by the simple addition of a venturi Feeding Tee.

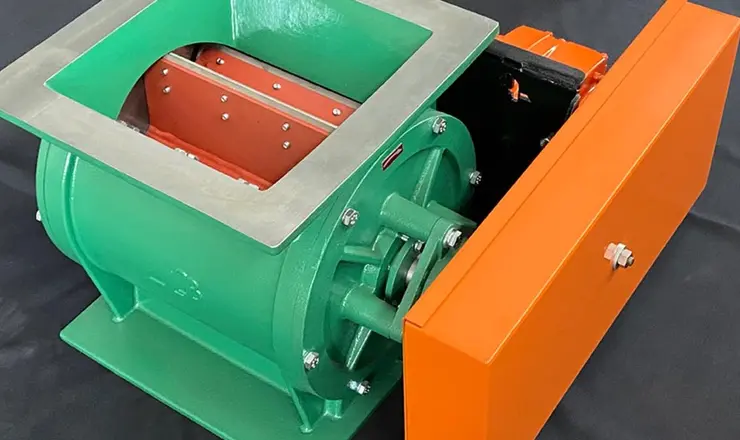

- Wear resistant ductile cast iron

- Universal flanges - will drill to any pattern

- Extra thick casing walls

- Multi-vane rotor. Adjustable SS tips. Improved seal.

- Outboard bearings

- Sizes from dia 200

- Minimal flange heights

- "The Green Valve" - environmentally-friendly product

- High stock levels - quick delivery times

Specifications

| MODEL | A | B | C | D | E | F | G | H | J | POWER |

| kW | ||||||||||

| 4BRVA200 | 200 | 300 | 300 | 150 | 2 | 125 | 12 | 405 | 305 | 0.37 |

| 4BRVA250 | 250 | 345 | 380 | 190 | 3 | 100 | 12 | 480 | 320 | 0.55 |

| 4BRVA300 | 305 | 400 | 460 | 230 | 3 | 117 | 12 | 465 | 360 | 0.75 |

| 4BRVA400 | 405 | 520 | 580 | 290 | 3 | 157 | 14 | 625 | 425 | 1.5 |

Downloads

FAQ's

What makes the 4B Cast Iron Rotary Feeders a green product?

The 4B Cast Iron Rotary Feeder Valves are not just painted green. - Rotary Valves are a critical part of cleaning the pollution from a plant. The polluted air is sucked through bag filters which are then pulsed and the dust is conveyed through a Rotary Valve & ultimately a waste product which is dumped safely. There is a differential air pressure in these bag houses, and of course the Rotary Valve is an Airlock and conveys the dust without losing pressure. Join us and help provide a cleaner, safer world for future generations.