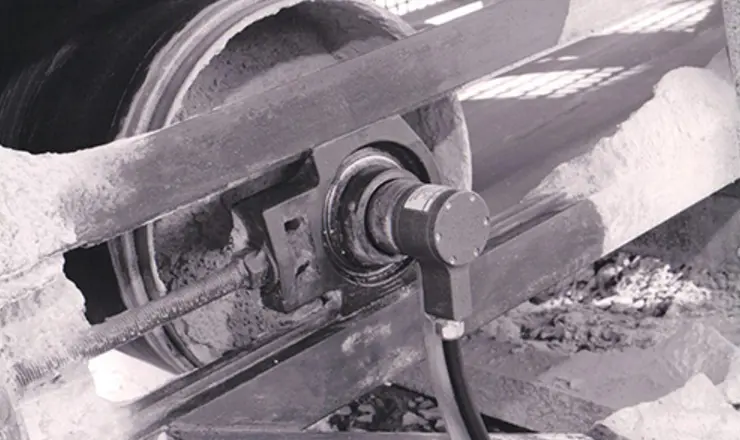

Encoder-Flex 1024 on pyörivä akselin kooderi, joka seuraa liukuportin asentoa, akselin asentoa tai akselin nopeutta. Esimerkkejä ovat hyllyportin, venttiilien, jakajien ja akselin nopeuden sijainti hitaasti liikkuvissa kuljettimissa, sekoittimissa ja kuivaimissa.

Encoder-Flex 1024 käyttää innovatiivista teknologiaa portin asennon tai akselin nopeuden seurantaan. Resoluutio on ohjelmoitavissa 1–1024 impulssia kierrosta kohti ja siinä on 4–20 mA:n lähtö sekä neliöpulssilähtö suunnanopeudelle ja Modbus RTU -tiedonsiirrolle edistyneen konfiguroinnin ja diagnostiikan mahdollistamiseksi.

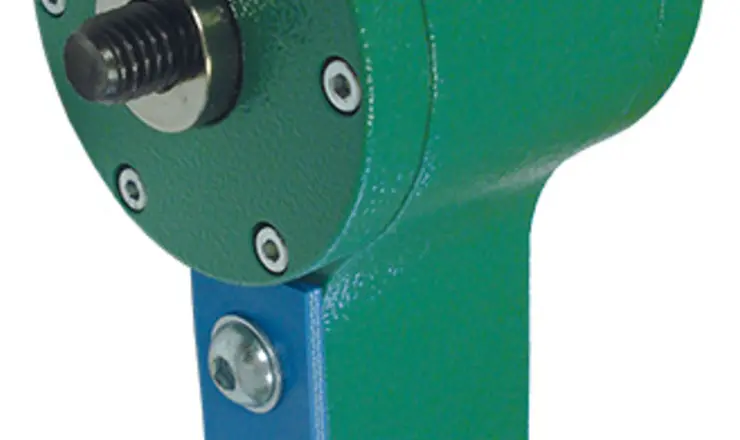

Siinä on kaksi tila-LEDiä helppoa käyttötilan ja kohteen havaitsemista varten. Laite voidaan nopeasti kalibroida magneetin kosketuksella akselin nopeutta, kulma-asentoa tai portin asentoa varten. Tiivis runko on valmistettu ruostumattomasta teräksestä.

- Valvoo akselin pyörimisnopeutta, kulmaa tai asentoa

- Lähdöt: 4-20 mA, kvadratuuripulssi (nopeus/suhteellinen pyörimisliike) ja RS485 Modbus RTU

- Ohjelmoitava resoluutio 1-1024 pulssia kierroksella

- Muistaa akselin asennon tehohäviön sattuessa

- Umpinainen ruostumattomasta teräksestä valmistettu kotelo