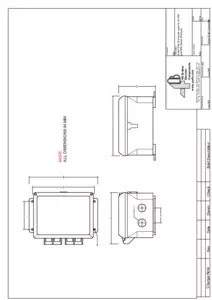

The Industrial Ethernet Node (IE-NODE) is a remote monitoring interface designed to provide sensor data to PLC’s or other automation and control systems.

Both units can be expanded to 16 sensor inputs with the installation of optional expansion boards.

The IE-NODE operates by reading its sensor inputs and sending processed data when requested by another system (e.g. PLC). The units are equipped with an RJ45 Ethernet socket and supports PROFINET, EtherNet/IP and Modbus TCP/IP protocols for easy integration with Siemens, Allen-Bradley Rockwell, Modicon and other PLC’s or automation devices.

The IE-NODE’s network configurator software provides a visual view of all devices on the network. It allows for easy identification of each unit on the network and allows for network settings to be changed as needed.

- Sensor Interface for PLC’s & Automation Systems

- Supports PROFINET, EtherNet/IP and Modbus TCP/IP protocols

- Up to 16 total sensor inputs with available expansion boards

- Configurator software for easy network setup and visual overview of all devices

Specifications

| Part Number | Description | Inputs | Supply Voltage | CSA | ATEX | IECEx |

| ETH-NODE1V46CAI | IE-NODE 1 | 8 Contact or NTC Temperature and 2 Pulse or Analog (4-20 mA) | 120 to 240 VAC / 24 VDC | Class II Div 2 | Zone 22 | Zone 22 |

| ETH-NODE1V4CAI | IE-NODE 1 | 8 Contact or NTC Temperature and 2 Pulse or Analog (4-20 mA) | 24 VDC | Class II Div 2 | Zone 21 | Zone 21 |

| ETH-NODE2V46CAI | IE-NODE 2 | 10 Analog (4-20 mA) | 120 to 240 VAC / 24 VDC | Class II Div 2 | Zone 22 | Zone 22 |

| ETH-NODE2V4CAI | IE-NODE 2 | 10 Analog (4-20 mA) | 24 VDC | Class II Div 2 | Zone 21 | Zone 21 |

| ETH-NODE-AUXI-6NTC | NTC Expansion Board | x | ||||

| ETH-NODE-AUXI-6AN | Analog Expansion Board | x |