A critical component for the reliable operation of the sidewall belt is the incorporation of fabrics or metallic wires that provide necessary transverse rigidity to the base belt.

The Beltsiflex system uses the most advanced fabrics providing superior stability and resisting the substantial forces at the critical flexing points, thus preventing deformation of the belt whilst retaining longitudinal flexibility.

Advantages of cross stability rigid belts:

- Provides better support on the return strand.

- Avoids the wear and tear of sidewalls and cleats.

- Prevents the crowning of the carrying surface al deflection points.

- Prevents the loss of driving power.

A wrong selection of the appropriate conveyor belt base during the construction of this product, without rigid frame or with inadequate frames can cause an inadequate performance of the system or in the best case, reduce product life time.

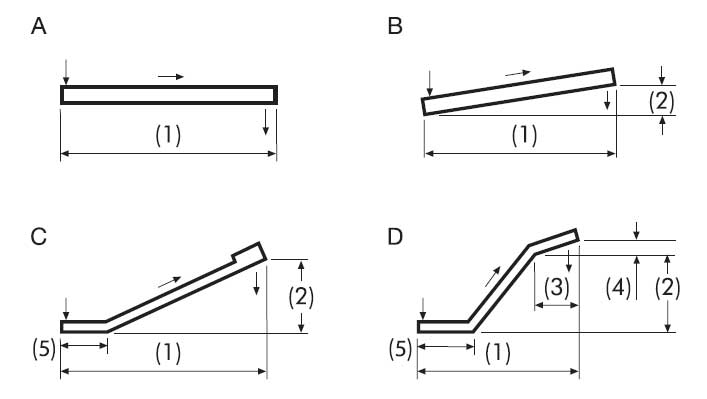

Types of Belts

Cross stability rigid fabric belts: Type "XEM"

Manufactured with fabric inserts, they are produced just as the BeltSiFLEX® elevated belting systems .

They provide greater stability than the common used EP fabrics (polyester-nylon) by adding to these one or two monofilament fabrics to achieve the rigidity most suitable for the belt´s characteristics.

All XEM, EMXSC and XWXSC belt types are manufactured in the following rubber compound varieties:

- N Abrasion resistant

- G Oil and grease resistant

- S Flame retarded

- RC Heat resistant up to 150 ºC

Cross stability rigid fabric belts: Type "EMXSC"

Manufactured with fabric inserts, they are produced just as the BeltSiFLEX® XEM type but differ from this in that their rigidity is achieved by inserting one or two metal cords across the band. This type of belt is recommended when the rigidity needed is not satisfied by the the XEM type. It is particularly indicated for the transportation of large prodcutions and heavy duty appliacations requiring significant width dimensions.

Cross stability rigid metal cord belts: Type "XWXSC"

This belt differs from type EMXSC in that it also incorporates metal cord tensioning along the belt and is used for the construction of big installations where the belt not only supports high productions, but is also of large dimensions. The elongation values of this type of belts are nearly null.

The weight and thickness of these belts will depend on the rubber cover applied in each case.