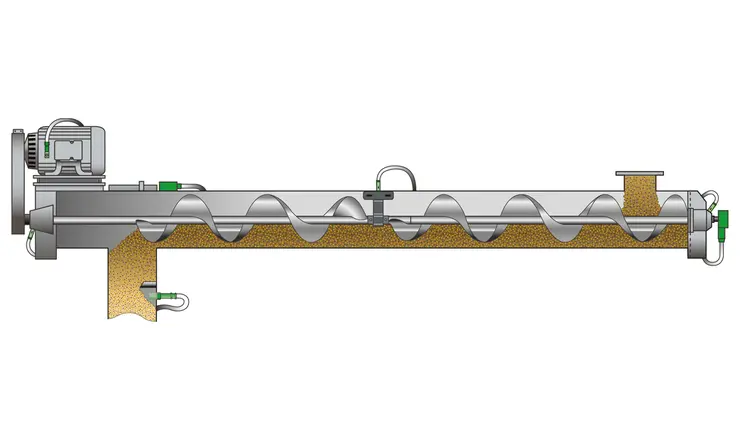

Screw Conveyor Monitoring

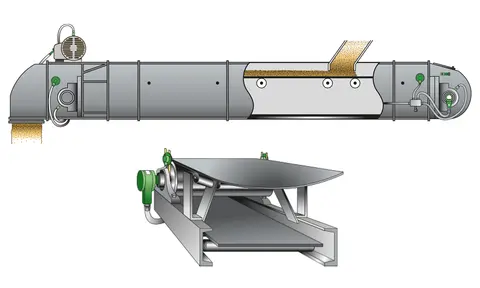

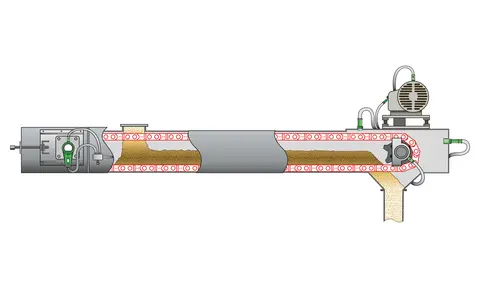

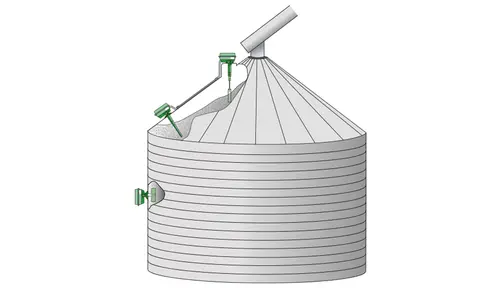

4B has a wide range of sensors for monitoring the various parts of your screw conveyor. The most common areas for monitoring include: bearing temperature, speed / motion, level / plug indication and door / gate position.

All of 4B's sensors can be connected to our hazard monitoring systems.

Screw Conveyor Monitoring

Sensors

Overheated bearings are one of the main risk factors for dust explosions in bucket elevators and need to be closely monitored.

4B offers a range of Atex, CSA and IECEx certified bearing temperature sensors and compatible monitoring systems.

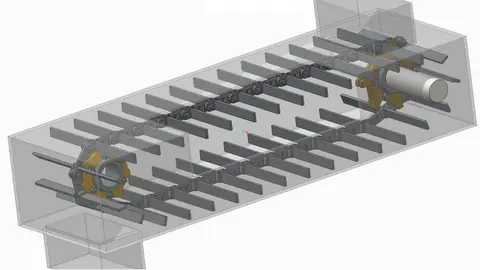

4B inductive proximity sensors are designed to detect shaft speed, shaft position, gate position or object presence. No contact is made between the sensor and the target being monitored.

View our full Electronics Catalogue here.

4B's line of speed switches includes: proximity, inductive, zero speed, stop motion and rotech encoders to monitor dangerous belt slip, underspeed or stop conditions on conveyors, bucket elevators and any other shaft driven machinery. Our non-contacting sensors can be used to detect screw conveyor flights, elevator bucket bolts and other moving ferrous targets. Speed switches can be connected to a PLC or to one of 4B’s hazard monitoring systems to provide alarm and/or shutdown of your machinery when dangerous conditions are detected.

View our full Electronics Catalogue here.