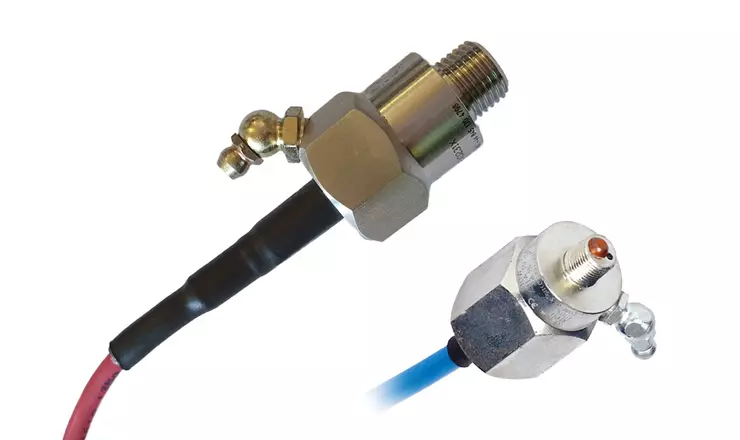

Unique low cost alarm/indicator panel for use with any 4B NTC-type temperature sensors. ADB810, WDB70, and WDB810 series sensors are recommended.

The T400N ELITE is able to accept signals from up to 8 NTC sensors (zones), which are separated into two groups of 4 zones. Each group of sensors is able to cause alarm and shutdown of individual machine when hazardous conditions are detected. There is a total of 2 Alarm and 2 Stop relays. The control unit is housed in a self contained wall mounting enclosure. A test push button on the lid of the control unit provides for full system verification. Alarm and status LEDs provide means of quick location of the alarm condition, and voltage free relay contacts provide separate alarm and shutdown control. An alarm mute push button is provided on the lid of the control unit and additional connections are provided for an external alarm mute functionality. A rotary switch is used to select the temperature alarm value.

- Monitors up to Eight Temperature Zones

- Can Monitor Two Separate Machines via 2 x Alarm and 2 x Stop Relays

- Selectable Alarm Temperature Level

- Configurable Alarm and Stop Delays

- LED Alarm Indication and Power Status

- Alarm Mute - Automatic Reactivation on New Alarm

- Test Feature – Externally Controlled Test Facility

- Dust Hazard Approved

Belt Conveyor

Bucket Elevator

Chain Conveyor

Screw Conveyor

Specifications

Part numbers:

- T4004NV4CAI - T400 NTC Elite Control Module - 24 VDC; ATEX and IECEx Zone 21 and Zone 22

- T4004NV46CAI - T400 NTC Elite Control Module - 110-240CAV 50/60Hz or 24VDC ATEX and IECEx Zone 22

Options / Accessories:

- TX400PLCB PLC Relay Board with 8 relays

- NTC Bearing Sensors (Type WDB or ADB )

Technical Specifications:

| T4004NV4CAI | T4004NV46CAI | ||

| Input Supply Voltage | 24 VDC (T4004NV4CAI) | 120 to 240 VAC or 24 VDC (T4004NV46CAI) | |

| Alarm Relay Contacts | Zone 1 - 1 Pole Normally Open - 8 A @ 250 VAC | Zone 1 - 1 Pole Normally Open - 8 A @ 250 VAC | |

| Zone 2 - 1 Pole Normally Open - 8 A @ 250 VAC | Zone 2 - 1 Pole Normally Open - 8 A @ 250 VAC | ||

| Stop Relay Contacts | Zone 1 - 1 Pole Normally Open - 8 A @ 250 VAC | Zone 1 - 1 Pole Normally Open - 8 A @ 250 VAC | |

| Zone 2 - 1 Pole Normally Open - 8 A @ 250 VAC | Zone 2 - 1 Pole Normally Open - 8 A @ 250 VAC | ||

| Sensor Inputs | Up To 8 NTC Thermistors | Up To 8 NTC Thermistors | |

| Sensor Supply | 24 VDC - 100 mA Maximum | 24 VDC - 100 mA Maximum | |

| Terminals | Power: 4 mm^2 - 14 AWG Maximum | Power: 4 mm^2 - 14 AWG Maximum | |

| Signals: 2.5 mm^2 - 16 AWG Maximum | Signals: 2.5 mm^2 - 16 AWG Maximum | ||

| Dimensions (H x W x D) | 9.7 x 7.4 x 4 (inches) / 246 x 188 x 102 (mm) | 9.7 x 7.4 x 4 (inches) / 246 x 188 x 102 (mm) | |

| Fixing Centres (H x W) | 8.75 x 4 (inches) / 222 x 102 (mm) | 8.75 x 4 (inches) / 222 x 102 (mm) | |

| Cable Entry | 2 Holes x 25mm Dia | 2 Holes x 25mm Dia | |

| Weight | 3 lbs / 1.3 Kg | 3 lbs / 1.3 Kg | |

| LED Status Indicators | Green LED - Power | Green LED - Power | |

| Green LED - Hot Bearing #1 through #8 | Green LED - Hot Bearing #1 through #8 | ||

| Red LED - Alarm | Red LED - Alarm | ||

| Push Buttons | Mute | Mute | |

| Test | Test | ||

| WARNING | WARNING |