SPS 超级 Starco™ 钢制畚斗

SPS 斗提机畚斗

4B 全新的 SPS 深型斗提畚斗系列产品是 4B 深入工程研究的最新成果,实现了最佳的单个畚斗容量,同时继续保持原 Starco™ 系列畚斗完美的填充和抛料特性和适应速度广的特点。

Product Features

- SPS 单个畚斗相比 Starco 畚斗容量得到提升,使用更少的畚斗却能使斗提机提升能力得到提升

- 完美的填充和抛料特性,物料适应范围宽广

- 皮带速度适应性宽广

- 无缝钢板深拉冲压成型,没有焊缝和接头

- 产品尺寸范围更广-最新尺寸可以到 630-215

Material

不锈钢畚斗,

碳钢制畚斗

Use by Industry

农业畚斗,

工业畚斗

Use by Product

粮食,

粒料与阳光农业,

粘性物料,

水泥,

轻工业,

重工业

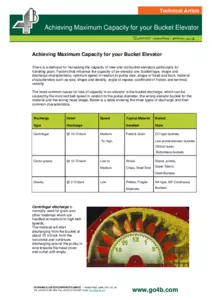

Specifications

| SPS Bucket | A | B | C | D | T/Kg | T/Kg | T/Kg | T/Kg | T/Kg | T/Kg | Cap. (L) | Cap. (L) | Holes | E | F | G | Max. | |

| STEEL | (mm) | (mm) | (mm) | (mm) | 1.0mm | 1.2mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm | Z2 (total) | Z3 (water) | No. | (dia mm) | (mm) | (mm) | Pcs/Mtr | |

| SPS 80-80 | 85 | 80 | 58 | 39 | 0.11 | 0.21 | 0.18 | 2 | 8 | 43 | 16 | 15 | ||||||

| SPS 100-90 | 106 | 89 | 66 | 45 | 0.12 | 0.18 | 0.4 | 0.33 | 0.25 | 2 | 8.5 | 50 | 20 | 14 | ||||

| SPS 100-100 | 105 | 97 | 78 | 46 | 0.18 | 0.42 | 0.29 | 2 | 8.5 | 50 | 25 | 12 | ||||||

| SPS 120-100 | 125 | 105 | 77 | 53 | 0.22 | 0.33 | 0.58 | 0.44 | 2 | 8 | 67 | 25 | 12 | |||||

| SPS 140-110 | 146 | 112 | 91 | 40 | 0.43 | 0.76 | 0.41 | 2 | 8.5 | 70 | 25 | 10.5 | ||||||

| SPS 130-120 | 138 | 120 | 90 | 62 | 0.3 | 0.38 | 0.83 | 0.65 | 2 | 8.5 | 70 | 25 | 10.5 | |||||

| SPS 140-120 | 146 | 120 | 90 | 62 | 0.4 | 0.8 | 0.87 | 0.65 | 2 | 8.5 | 70/86* | 25 | 10.5 | |||||

| SPS 160-140 | 166 | 147 | 112 | 78 | 0.55 | 0.73 | 1.1 | 1.58 | 1.2 | 2 | 8.5 | 100 | 30 | 8.6 | ||||

| SPS 180-140 | 187 | 147 | 112 | 78 | 0.61 | 0.81 | 1.22 | 1.75 | 1.35 | 2 | 8.5 | 100 | 30 | 8.6 | ||||

| SPS 200-150 | 205 | 150 | 112 | 77 | 0.77 | 1.03 | 1.54 | 2 | 1.53 | 2 | 9 | 100/102* | 32 | 8.6 | ||||

| SPS 230-160/A | 233 | 160 | 122 | 85 | 0.86 | 1.15 | 1.72 | 2.72 | 2.05 | 3 | 9 | 70 | 32 | 8 | ||||

| SPS 230-160/B | 233 | 160 | 122 | 85 | 0.86 | 1.15 | 1.72 | 2.72 | 2.05 | 2 | 10.5 | 120 | 32 | 8 | ||||

| SPS 240-160/A | 247 | 165 | 130 | 92 | 1.35 | 2 | 3.03 | 2.37 | 3 | 10.5 | 70/77* | 35 | 7.4 | |||||

| SPS 240-160/B | 247 | 165 | 130 | 92 | 1.35 | 2 | 3.03 | 2.37 | 2 | 10.5 | 140 | 35 | 7.4 | |||||

| SPS 240-160/C | 247 | 165 | 130 | 92 | 1.35 | 2 | 3.03 | 2.37 | 2 | 10.5 | 120 | 35 | 7.4 | |||||

| SPS 260-165 | 262 | 165 | 130 | 92 | 1.38 | 2.1 | 3.28 | 2.55 | 3 | 10.5 | 77/80* | 35 | 7.4 | |||||

| SPS 280-165 | 289 | 167 | 132 | 93 | 1.55 | 2.32 | 3.78 | 2.8 | 3 | 10.5 | 80 | 38 | 7.4 | |||||

| SPS 300-165/A | 308 | 165 | 135 | 94 | 1.65 | 2.08 | 2.5 | 3.88 | 2.9 | 3 | 9 | 100/104* | 36 | 7.2 | ||||

| SPS 300-165/B | 308 | 165 | 135 | 94 | 1.65 | 2.08 | 2.5 | 3.88 | 2.9 | 3 | 11 | 100 | 36 | 7.2 | ||||

| SPS 330-165 | 340 | 165 | 135 | 97 | 1.9 | 2.37 | 2.85 | 4.4 | 3.5 | 3 | 11 | 110/120* | 38 | 7.2 | ||||

| SPS 350-165/A | 360 | 165 | 135 | 94 | 2.12 | 3.2 | 4.5 | 3.65 | 4 | 9 | 90 | 38 | 7.2 | |||||

| SPS 350-165/B | 360 | 165 | 135 | 94 | 2.12 | 3.2 | 4.5 | 3.65 | 3 | 11 | 120 | 38 | 7.2 | |||||

| new | SPS 230-170 | 235 | 170 | 132 | 93 | 1.4 | 3.09 | 2.4 | 2 | 11 | 120 | 35 | 7 | |||||

| SPS 200-180 | 204 | 182 | 140 | 98 | 1.28 | 2.84 | 2.17 | 2 | 11 | 110 | 44 | 7 | ||||||

| SPS 260-180 | 270 | 188 | 140 | 96 | 1.58 | 4.1 | 4.1 | 3.2 | 3 | 11 | 80 | 45 | 7 | |||||

| SPS 280-180 | 290 | 185 | 140 | 97 | 1.7 | 2.55 | 4.4 | 3.3 | 3 | 11 | 80 | 38 | 7 | |||||

| SPS 300-180/A | 308 | 182 | 140 | 95 | 1.8 | 2.7 | 4.5 | 3.5 | 3 | 9 | 100/104* | 36 | 7 | |||||

| SPS 300-180/B | 308 | 182 | 140 | 95 | 1.8 | 2.7 | 4.5 | 3.5 | 3 | 11 | 100 | 36 | 7 | |||||

| SPS 330-180 | 340 | 182 | 140 | 98 | 2 | 5.2 | 4 | 3 | 11 | 110/120* | 38 | 7 | ||||||

| SPS 350-180/A | 362 | 182 | 140 | 98 | 2.1 | 3.15 | 5.4 | 4.2 | 4 | 9 | 90 | 38 | 7 | |||||

| SPS 350-180/B | 362 | 182 | 140 | 98 | 2.1 | 3.15 | 5.4 | 4.2 | 3 | 11 | 120 | 38 | 7 | |||||

| SPS 370-180 | 385 | 195 | 140 | 95 | 2.24 | 2.8 | 6.4 | 4.9 | 4 | 11 | 90 | 38 | 7 | |||||

| SPS 250-215 | 257 | 215 | 162 | 113 | 1.86 | 5.3 | 4.1 | 3 | 11 | 85 | 49 | 5.88 | ||||||

| SPS 280-215 | 294 | 215 | 163 | 114 | 2.18 | 2.86 | 3.08 | 6.04 | 4.7 | 3 | 11 | 80 | 50 | 5.88 | ||||

| SPS 300-215 | 310 | 220 | 163 | 112 | 2.32 | 2.9 | 3.48 | 6.7 | 5.2 | 3 | 11 | 100 | 50 | 5.88 | ||||

| SPS 330-215 | 340 | 215 | 163 | 112 | 2.97 | 3.56 | 7.2 | 5.65 | 3 | 11 | 120 | 50 | 5.88 | |||||

| SPS 350-215 | 362 | 215 | 163 | 112 | 3.23 | 3.87 | 7.6 | 5.86 | 3 | 11 | 120 | 50 | 5.88 | |||||

| SPS 370-215 | 381 | 215 | 163 | 112 | 3.32 | 4 | 8.1 | 6.3 | 4 | 11 | 90 | 50 | 5.88 | |||||

| SPS 440-215 | 450 | 225 | 165 | 113 | 3.92 | 4.68 | 9.83 | 7.44 | 4 | 11 | 110 | 50 | 5.88 | |||||

| SPS 450-215 | 464 | 215 | 163 | 113 | 4 | 4.8 | 9.95 | 7.9 | 5 | 11 | 88/90* | 50 | 5.88 | |||||

| SPS 470-215 | 480 | 225 | 165 | 113 | 4.14 | 4.95 | 10.56 | 8.06 | 4 | 11 | 120 | 50 | 5.88 | |||||

| SPS 500-215 | 515 | 215 | 163 | 113 | 4.28 | 5.14 | 11.25 | 8.8 | 5 | 11 | 100 | 50 | 5.88 | |||||

| new | SPS 630-215 | 630 | 220 | 164 | 113 | 7.4 | 14.29 | 10.92 | 7 | 11 | 90 | 50 | 5.88 |

T = Thickness in mm

Special holes/thicknesses/wearbands - available on request

Wear band size: 3.0mm on 1 or 3 sides on request.

* Slotted holes to fit alternate hole centres

For Stainless Steel, see price list for thickness options !