Major London port import/export grain terminal had a serious conveyor fire causing substantial damage to the facility. It required a hazard monitoring solution that was ATEX approved, industry 4.0 and industrial IoT compliant to make the investment future proof and expandable.

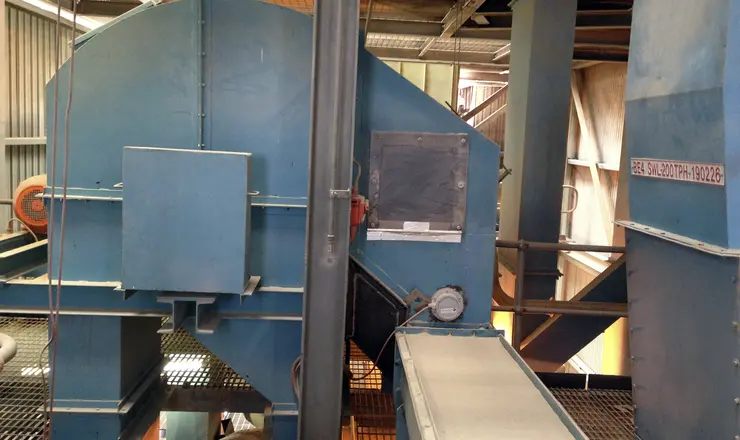

Major London port import/export grain terminal had a serious conveyor fire caused initially by a collapsed bearing. The fire spread to ancillary equipment and caused several hundred thousand pounds worth of damage. The port terminal has more than 50 conveyors and elevators, most are operated every day and run at high speeds. The elevators are over 65m in height and the larger conveyors run in both directions, all of which adds to the challenges. The grain terminal which is over 1km in length and can store in excess of 250,000t of grain had over 300 critical sensing points identified. The Port Authority required the solution to be ATEX approved, industry 4.0 and industrial IoT compliant to make the investment future proof and expandable.

Major London port import/export grain terminal had a serious conveyor fire caused initially by a collapsed bearing. The fire spread to ancillary equipment and caused several hundred thousand pounds worth of damage. The port terminal has more than 50 conveyors and elevators, most are operated every day and run at high speeds. The elevators are over 65m in height and the larger conveyors run in both directions, all of which adds to the challenges. The grain terminal which is over 1km in length and can store in excess of 250,000t of grain had over 300 critical sensing points identified. The Port Authority required the solution to be ATEX approved, industry 4.0 and industrial IoT compliant to make the investment future proof and expandable.

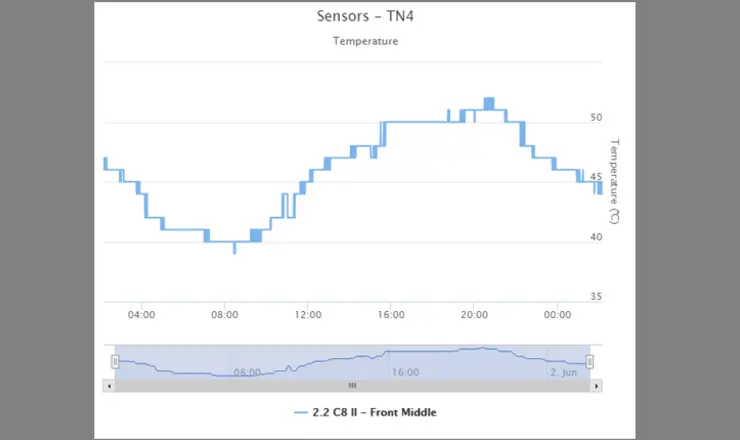

The Port Authority made use of the 4B in-house technical expertise and experienced installation team who delivered a full “Turn-Key” solution, training and ongoing support. 4B award-winning IoT solution Hazardmon.com was utilised as the framework of this project. 4B’s proprietary and industry leading HOTBUS communication platform was selected as a means of connecting all the sensors together and aggregating the data. The sensors are continuously monitored, and the resulting data is analysed in the cloud enabling predictive analysis and smart reporting. Management and operators quickly embraced the system benefits with information being readily available via web enabled devices both on and off-site. This solution was selected to be flexible, scalable and robust.

The Port Authority made use of the 4B in-house technical expertise and experienced installation team who delivered a full “Turn-Key” solution, training and ongoing support. 4B award-winning IoT solution Hazardmon.com was utilised as the framework of this project. 4B’s proprietary and industry leading HOTBUS communication platform was selected as a means of connecting all the sensors together and aggregating the data. The sensors are continuously monitored, and the resulting data is analysed in the cloud enabling predictive analysis and smart reporting. Management and operators quickly embraced the system benefits with information being readily available via web enabled devices both on and off-site. This solution was selected to be flexible, scalable and robust.

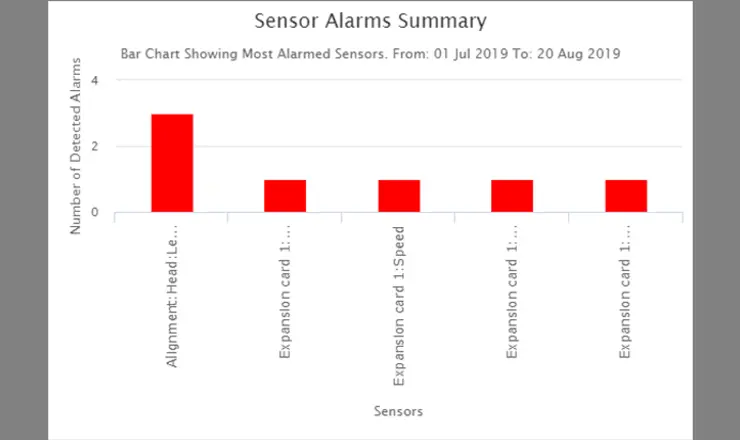

- Explosion risk mitagation:prevented at least three incidents since installation

- Proactive maintenance: reduced the number of belt misalignment conditions by a factor of 20 (2000%)

- Improved operational safety: All staff are now warned of hazards immediately by Email / SMS and remedial action can be taken with the highest priority

- Satisfied insurance requirements

- Explosion risk mitagation:prevented at least three incidents since installation

- Proactive maintenance: reduced the number of belt misalignment conditions by a factor of 20 (2000%)

- Improved operational safety: All staff are now warned of hazards immediately by Email / SMS and remedial action can be taken with the highest priority

- Satisfied insurance requirements