- Magnetic Proximity Belt Speed and Belt Alignment Sensor

- Adjustable Sensing Range 25mm to 75 mm

- LED Indication

- Mounting Bracket Included

- ½” NTP Conduit Entry

- Stainless Steel Construction

- High Temperature Version Available

- IP66 Protection

Hastighetsvakter

4B's line of speed switches includes: proximity, inductive, zero speed, stop motion and rotech encoders to monitor dangerous belt slip, underspeed or stop conditions on conveyors, bucket elevators and any other shaft driven machinery. Our non-contacting sensors can be used to detect screw conveyor flights, elevator bucket bolts and other moving ferrous targets. Speed switches can be connected to a PLC or to one of 4B’s hazard monitoring systems to provide alarm and/or shutdown of your machinery when dangerous conditions are detected.

View our full Electronics Catalogue here.

- Monitors shaft speed, angle, or position

- Outputs: 4-20 mA, Quadrature Pulse (Speed/Relative Rotation), and RS485 Modbus RTU

- Programmable resolution from 1 to 1024 Pulses per Revolution

- Compatible with gates with up to 500,000 rotations between closed and open positions

- Connects directly to control systems (PLC, SCADA, Watchdog, IE-Node, etc)

- Memorizes shaft position in the case of a power loss

- Simple magnetic calibration

- Comprehensive software for access to advanced programming and visualization

- Sealed stainless steel enclosure

- LED Status Indicators

- ATEX and IECEx Zone 20 (Dust) and Zone 0 (Gas) Approved

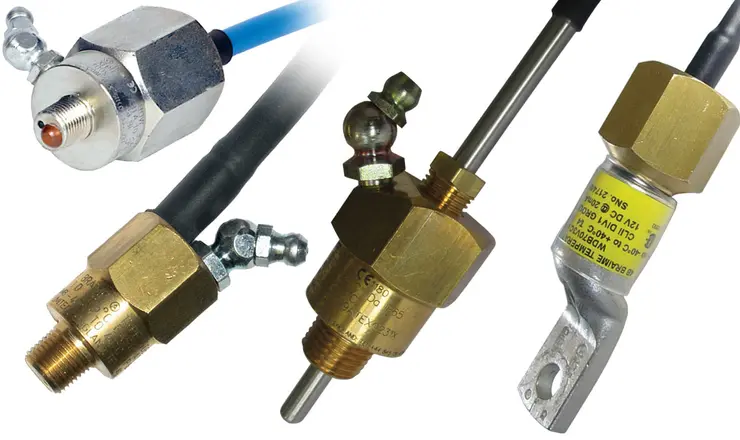

- Signals underspeed for bucket elevators, conveyors and all rotating machinery

- Inductive proximity sensor in 30mm diameter housing, which detects rotating metal target

- 20% underspeed set point

- 2 wire & 5 wire versions available

- Easy and reliable calibration procedure by using a magnet

- Non-contacting & failsafe

- Compatible with the Whirligig speed sensor mount

- 24-240 VAC/VDC multi voltage power supply

- 2-wire

- IP66 rated

- M18 x 1.0 ISO threaded nylon body

- Green and Blue LEDs showing output state

- 6 mm detection range

- No calibration needed

- 4s start up delay

- 4 - 20 mA Output

- Simple Magnetic Calibration

- Loop Powered (2 Wire)

- Totally Sealed Construction: Submersible

- Built In Conduit Adaptor (1/2” NPT)

- Easy Installation with Whirligig® Sensor Mount

- SpeedMaster™ Compatible for Accurate Testing

- Microprocessor controlled speedswitch

- Signals underspeed conditions for bucket elevators, conveyors and all rotating machinery

- Inductive proximity sensor, in DIN style housing, which detects a rotating metal target

- Dual set-points at 10% and 20% underspeed

- Non-contacting & failsafe

- Compatible with the Whirligig speed sensor mount

- Magnetic Proximity Belt Speed and Belt Alignment Sensor

- Detects Moving Steel Ferrous Targets

- Adjustable Sensing Range of 25 – 75mm

- Not Affected by Material Build Up

- Stainless Steel Construction

- High Temperature Version Available

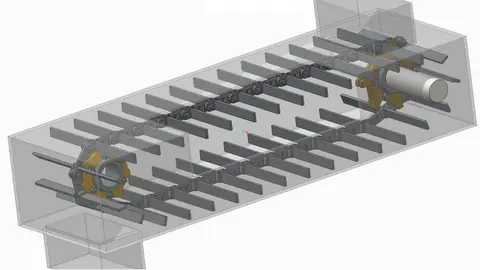

- Fully Guarded Target for Easy Mounting of Motion Sensors

- For DIN Style and Standard Cylindrical Inductive Sensors

- Easy Installation - Only Requires M12 Tapped Hole in the Machines Shaft or Use a Mag-Con™ for Magnetic Connection

- Available with 1, 2, 4 and 8 Targets per revolution

- Works with All 4B Speed Switches and Inductive Sensors

- Heavy duty shaft sensor mount

- Manufactured in stainless steel casing for heavy duty usage

- Suitable for all Braime sensors & other industry standard cylindrical sensors

- Not affected by shaft or machine vibration

- 2/4 pulse target (as standard)

- Easy to install, safe

- Rotating shaft monitor

- Polypropylene housing

- For light duty applications, IP66

- Provides information on shaft speed, direction, position or revolution

- For conveyors, elevators, mixers, fans, pumps, grinders & other mechanical handling systems

- Compatible with the "Magcon" quick-connect device

- Rotating shaft monitor

- Aluminium housing

- Provides information on shaft speed, direction, position or revolution

- For conveyors, elevators, mixers, fans, pumps, grinders & other mechanical handling systems

- Heavy duty versions - suitable for the most severe industrial environments, IP65

- Compatible with the "Magcon" quick-connect device

- Rotating shaft monitor

- 304/316 stainless steel housing

- Provides information on shaft speed, direction, position or revolution

- For conveyors, elevators, mixers, fans, pumps, grinders & other mechanical handling systems

- Ultra heavy duty version - suitable for the most severe industrial environments

- IP67

- Heavy-duty belt speed monitor

- Monitors belt speed, slip & distance

- Totally enclosed & self contained trailing arm running on return side of conveyor belt

- Maintenance free for maximum reliability

- Non standard wheel diameters available

- 1 to 1,000 pulses per revolution

- Multiple Outputs

- Intrinsically safe option available

- -25 to +100 deg Celsius versions

- IP67

- Stopped Motion Monitor

- Inductive Proximity Sensor

- Single Trip Set Point

- Totally Sealed Construction (Submersible)

- Non-Contacting and Fail-Safe

- Microprocessor controlled underspeed monitor

- Signals underspeed for bucket elevators, conveyors and all rotating machinery

- Inductive proximity sensor in 30mm diameter housing, which detects rotating metal target

- Single set-point ~ 20% underspeed 2 wire & 5 wire versions available

- Non-contacting & failsafe

- Compatible with the Whirligig speed sensor mount