- Magnetic Proximity Belt Speed and Belt Alignment Sensor

- Adjustable Sensing Range 25mm to 75 mm

- LED Indication

- Mounting Bracket Included

- ½” NTP Conduit Entry

- Stainless Steel Construction

- High Temperature Version Available

- IP66 Protection

Switch Kecepatan

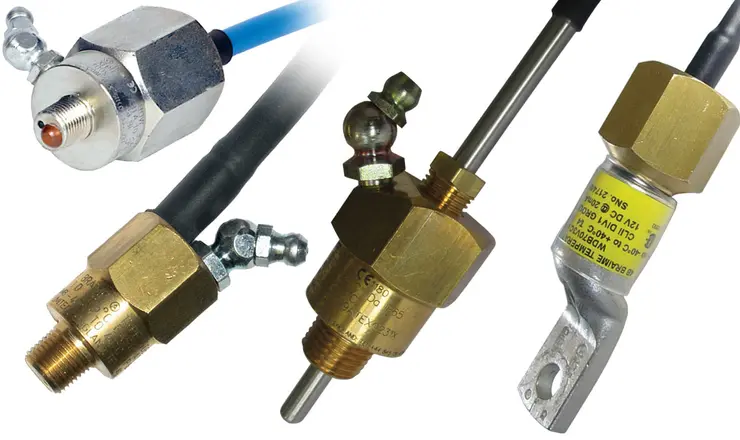

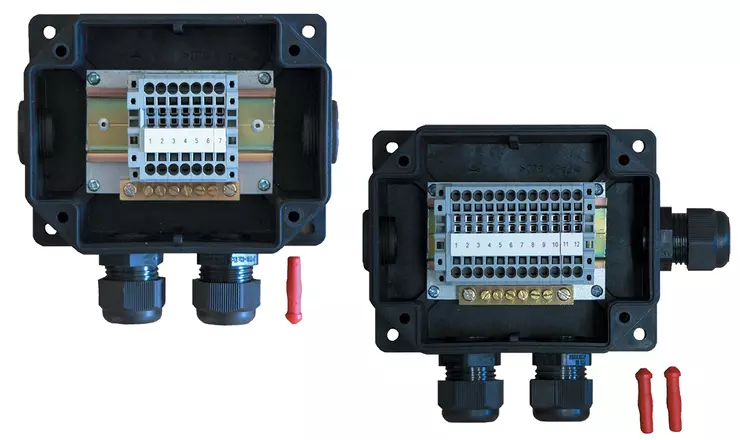

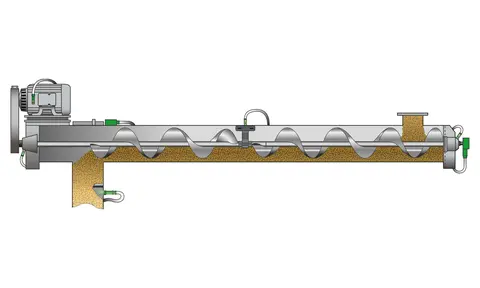

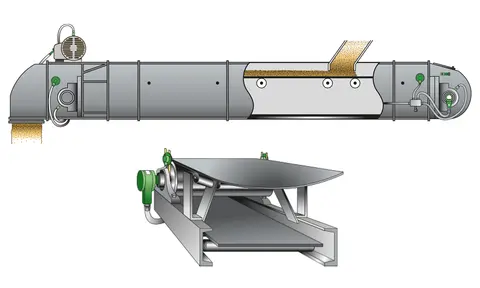

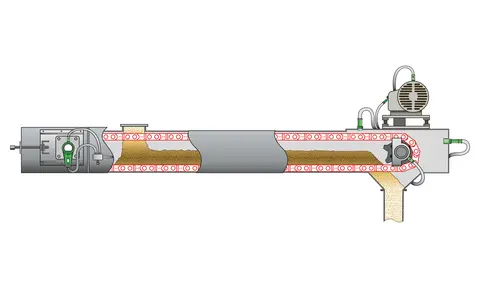

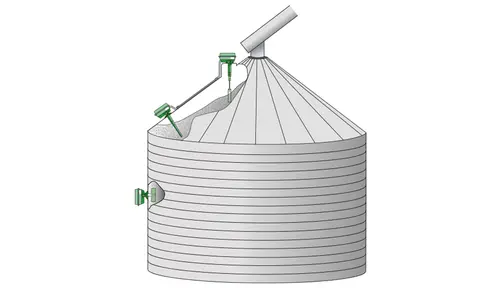

Jajaran switch kecepatan 4B meliputi: proximity, induktif, zero speed, stop motion, dan rotary encoder untuk memantau selip pada belt yang berbahaya, kecepatan terlalu rendah, atau kondisi berhenti pada conveyor, bucket elevator, dan mesin lain yang digerakkan oleh shaft. Sensor non-kontak kami dapat digunakan untuk mendeteksi scraper pada screw conveyor, baut bucket elevator, dan target bergerak lainnya yang berbahan besi. Switch kecepatan dapat dihubungkan ke PLC atau ke salah satu sistem pemantauan bahaya 4B untuk memberikan alarm dan/atau mematikan mesin Anda saat kondisi berbahaya terdeteksi.

Lihat Katalog Elektronik lengkap kami di sini.

- Monitors shaft speed, angle, or position

- Outputs: 4-20 mA, Quadrature Pulse (Speed/Relative Rotation), and RS485 Modbus RTU

- Programmable resolution from 1 to 1024 Pulses per Revolution

- Compatible with gates with up to 500,000 rotations between closed and open positions

- Connects directly to control systems (PLC, SCADA, Watchdog, IE-Node, etc)

- Memorizes shaft position in the case of a power loss

- Simple magnetic calibration

- Comprehensive software for access to advanced programming and visualization

- Sealed stainless steel enclosure

- LED Status Indicators

- ATEX and IECEx Zone 20 (Dust) and Zone 0 (Gas) Approved

- Signals underspeed for bucket elevators, conveyors and all rotating machinery

- Inductive proximity sensor in 30mm diameter housing, which detects rotating metal target

- 20% underspeed set point

- 2 wire & 5 wire versions available

- Easy and reliable calibration procedure by using a magnet

- Non-contacting & failsafe

- Compatible with the Whirligig speed sensor mount

- 24-240 VAC/VDC multi voltage power supply

- 2-wire

- IP66 rated

- M18 x 1.0 ISO threaded nylon body

- Green and Blue LEDs showing output state

- 6 mm detection range

- No calibration needed

- 4s start up delay

- 4 - 20 mA Output

- Simple Magnetic Calibration

- Loop Powered (2 Wire)

- Totally Sealed Construction: Submersible

- Built In Conduit Adaptor (1/2” NPT)

- Easy Installation with Whirligig® Sensor Mount

- SpeedMaster™ Compatible for Accurate Testing

- Microprocessor controlled speedswitch

- Signals underspeed conditions for bucket elevators, conveyors and all rotating machinery

- Inductive proximity sensor, in DIN style housing, which detects a rotating metal target

- Dual set-points at 10% and 20% underspeed

- Non-contacting & failsafe

- Compatible with the Whirligig speed sensor mount

- Magnetic Proximity Belt Speed and Belt Alignment Sensor

- Detects Moving Steel Ferrous Targets

- Adjustable Sensing Range of 25 – 75mm

- Not Affected by Material Build Up

- Stainless Steel Construction

- High Temperature Version Available

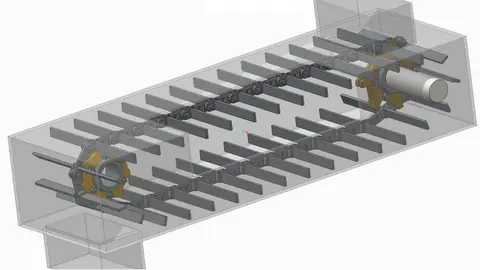

- Fully Guarded Target for Easy Mounting of Motion Sensors

- For DIN Style and Standard Cylindrical Inductive Sensors

- Easy Installation - Only Requires M12 Tapped Hole in the Machines Shaft or Use a Mag-Con™ for Magnetic Connection

- Available with 1, 2, 4 and 8 Targets per revolution

- Works with All 4B Speed Switches and Inductive Sensors

- Heavy duty shaft sensor mount

- Manufactured in stainless steel casing for heavy duty usage

- Suitable for all Braime sensors & other industry standard cylindrical sensors

- Not affected by shaft or machine vibration

- 2/4 pulse target (as standard)

- Easy to install, safe

- Rotating shaft monitor

- Polypropylene housing

- For light duty applications, IP66

- Provides information on shaft speed, direction, position or revolution

- For conveyors, elevators, mixers, fans, pumps, grinders & other mechanical handling systems

- Compatible with the "Magcon" quick-connect device

- Rotating shaft monitor

- Aluminium housing

- Provides information on shaft speed, direction, position or revolution

- For conveyors, elevators, mixers, fans, pumps, grinders & other mechanical handling systems

- Heavy duty versions - suitable for the most severe industrial environments, IP65

- Compatible with the "Magcon" quick-connect device

- Rotating shaft monitor

- 304/316 stainless steel housing

- Provides information on shaft speed, direction, position or revolution

- For conveyors, elevators, mixers, fans, pumps, grinders & other mechanical handling systems

- Ultra heavy duty version - suitable for the most severe industrial environments

- IP67

- Heavy-duty belt speed monitor

- Monitors belt speed, slip & distance

- Totally enclosed & self contained trailing arm running on return side of conveyor belt

- Maintenance free for maximum reliability

- Non standard wheel diameters available

- 1 to 1,000 pulses per revolution

- Multiple Outputs

- Intrinsically safe option available

- -25 to +100 deg Celsius versions

- IP67

- Stopped Motion Monitor

- Inductive Proximity Sensor

- Single Trip Set Point

- Totally Sealed Construction (Submersible)

- Non-Contacting and Fail-Safe

- Microprocessor controlled underspeed monitor

- Signals underspeed for bucket elevators, conveyors and all rotating machinery

- Inductive proximity sensor in 30mm diameter housing, which detects rotating metal target

- Single set-point ~ 20% underspeed 2 wire & 5 wire versions available

- Non-contacting & failsafe

- Compatible with the Whirligig speed sensor mount