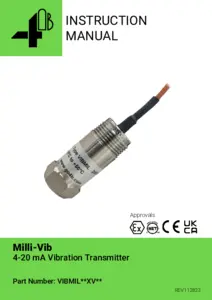

VIBMIL is a vibration sensor designed for continuous monitoring of vibration levels in industrial environments. It is current loop powered accelerometer and delivers accurate vibration RMS velocity using a 4-20 mA output. Built with a stainless-steel enclosure, including a 3/4” NPT thread for conduit connection. The VIBMIL can be supplied with optional inbuilt NTC or PT100 temperature sensors (Milli-Con version).

The VIBMIL is equipped with female 1/4”-28 UNF female mounting thread, allowing the use of a screw, stud, or mounting stud to secure the sensor to the desired application.

The sensor is supplied with a 1/4”-28 UNF set screw as standard. Optional converters to M8 and M6 male threads are available.

To achieve maximum sensitivity, mount the sensor vertically along the Y-axis of the machinery.

To ensure accurate readings and proper functioning of the VIBMIL, securely fix it to a level surface during installation.

Implement the 2 wire, loop powered accelerometer into the desired control system and measure the linearised output from 4 – 20mA proportional to the sensors measuring range.

- Robust, compact, IP66 Stainless Steel enclosure

- Monitors RMS velocity in mm/s

- Measuring range 0-25 mm/s standard, and 0-50 mm/s special request

- Can also monitor surface temperature with optional NTC or PT100 temperature sensor (Milli-Con version)

- 2 wire 4-20mA loop powered sensor

- 3/4” NPT conduit fitting

- 1/4” – 28 Female UNF mounting thread.

Downloads

Design Services

Hazard Monitoring Design Service

Hazard Monitoring Design Service

Preventative maintenance can help reduce the risk of equipment failure and consequent downtimes. When it comes to monitoring your bucket elevators and belt conveyors, 4B can recommend you the ideal combination of sensors and monitoring systems to suit your requirements and budget.

4B provides an extensive range of their own ATEX / IECEx / CSA approved hazard monitoring systems, misalignment switches and bearing temperature monitors and level controls. We can offer you anything from a replacement sensor to a fully integrated hazard monitoring system which can be operated either as a stand-alone system or connected to your PLC.

And if you do not want to install hazard monitoring sensors on every piece of equipment in your plant straightaway, we can offer you a scalable solution starting with carefully chosen equipment and systems that can be expanded at a later date to encompass other machines in the plant.

We can also offer you an installation service, and we do provide a competent after-sales technical service to help you overcome any technical problems with your monitoring equipment.

To get a recommendation from our engineers, please fill in the electronics questionnaire below. Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.

Preventative maintenance can help reduce the risk of equipment failure and consequent downtimes. When it comes to monitoring your bucket elevators and belt conveyors, 4B can recommend you the ideal combination of sensors and monitoring systems to suit your requirements and budget.

4B provides an extensive range of their own ATEX / IECEx / CSA approved hazard monitoring systems, misalignment switches and bearing temperature monitors and level controls. We can offer you anything from a replacement sensor to a fully integrated hazard monitoring system which can be operated either as a stand-alone system or connected to your PLC.

And if you do not want to install hazard monitoring sensors on every piece of equipment in your plant straightaway, we can offer you a scalable solution starting with carefully chosen equipment and systems that can be expanded at a later date to encompass other machines in the plant.

We can also offer you an installation service, and we do provide a competent after-sales technical service to help you overcome any technical problems with your monitoring equipment.

To get a recommendation from our engineers, please fill in the electronics questionnaire below. Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.