A malting facility repurposed a grain elevator to transport "green malt" and found that the elevator was not functioning properly. 4B reduced the elevator pulley size and RPM to give the correct discharge, and modified the outlet. Elevator running smoother with less loading on the motor.

To utilise an existing Grain Elevator to transport “green malt”.

After installation it was apparent the elevator was problematic and not functioning as expected. The installed buckets were CCS127 buckets, which replaced the obsolete J127 HDP buckets which were originally installed.

After some discussion with 4B, the prognosis was the pulley may be too small for the projection of the CCS12x7 bucket. This was expected to be cured by installing CCS 12x6 but the problem still persisted although not as bad.

To utilise an existing Grain Elevator to transport “green malt”.

After installation it was apparent the elevator was problematic and not functioning as expected. The installed buckets were CCS127 buckets, which replaced the obsolete J127 HDP buckets which were originally installed.

After some discussion with 4B, the prognosis was the pulley may be too small for the projection of the CCS12x7 bucket. This was expected to be cured by installing CCS 12x6 but the problem still persisted although not as bad.

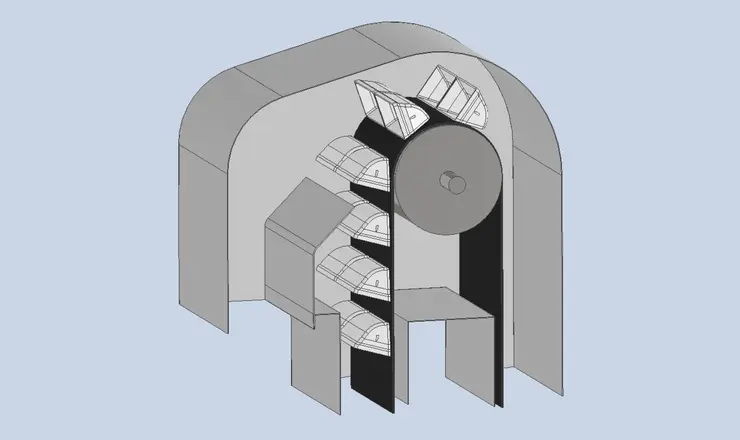

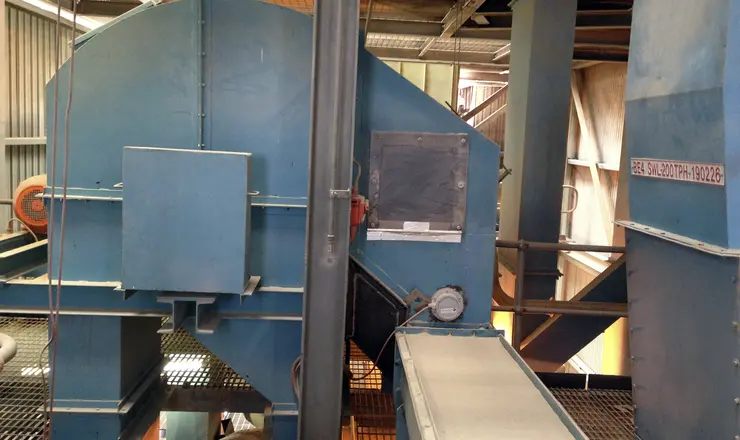

After a site visit to inspect what they actually had, it was apparent the elevator was set up to transport free flowing grain. This setup was incorrect for the handling of green malt, which by nature is wet and sticky and does not flow well.

The conclusion was the product was not fully discharging into the outlet but was in fact falling down the return leg back into the boot.

4B recommended two minor alterations to solve this problem.

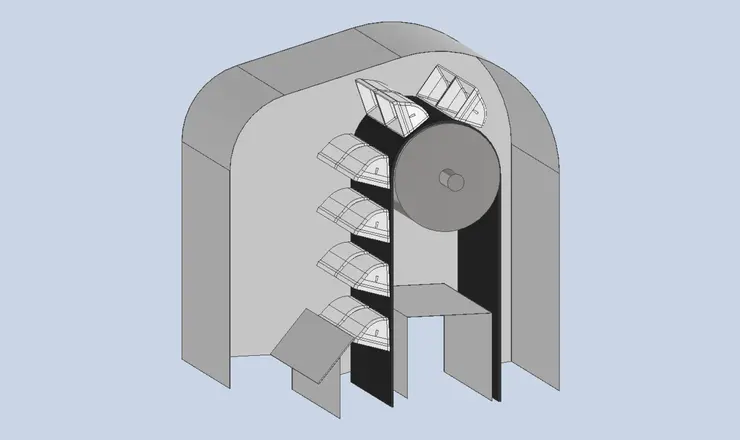

- Modify the outlet by lowering it into a suitable position to ensure complete discharge of the product from the bucket into the outlet.

- Reduce the RPM of the pulley to give the correct discharge stream.

After a site visit to inspect what they actually had, it was apparent the elevator was set up to transport free flowing grain. This setup was incorrect for the handling of green malt, which by nature is wet and sticky and does not flow well.

The conclusion was the product was not fully discharging into the outlet but was in fact falling down the return leg back into the boot.

4B recommended two minor alterations to solve this problem.

- Modify the outlet by lowering it into a suitable position to ensure complete discharge of the product from the bucket into the outlet.

- Reduce the RPM of the pulley to give the correct discharge stream.

After implementation of both these modifications the problem completely ceased to exist. The feedback was positive. The elevator ran smoother with less loading on the motor. The batch time was reduced to the point where it is now the most efficient part of the process.

After implementation of both these modifications the problem completely ceased to exist. The feedback was positive. The elevator ran smoother with less loading on the motor. The batch time was reduced to the point where it is now the most efficient part of the process.