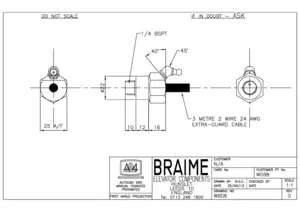

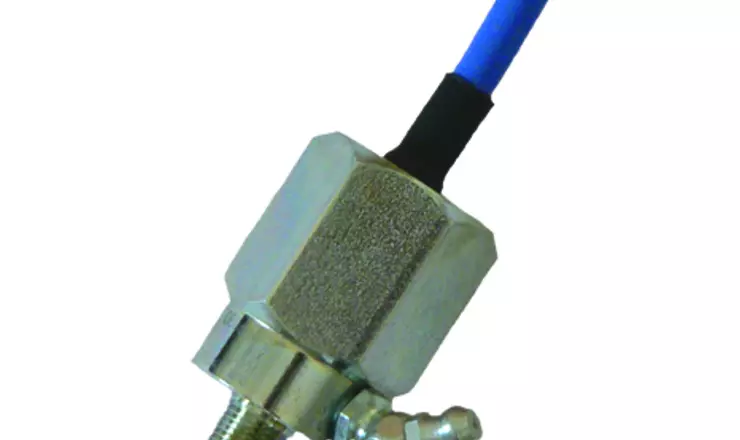

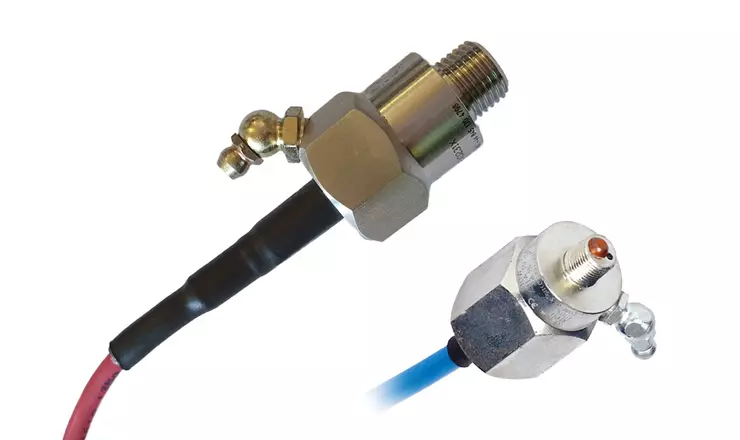

The WDB series bearing sensors are designed to screw directly into a bearing housing. Each sensor is fitted with a grease zerk to allow lubrication of the bearing without the need for removal of the sensor.

The WDB8 series have a 1/4” BSPT thread. The WDB2 series have a 1/8” NPT thread. Three versions are available; an NTC thermistor or Pt100 RTD type for continuous temperature monitoring, and a PTC thermistor model with the following trip points (specify when ordering): 60°C, 70°C, 80°C, 90°C for step (Cold/Hot) temperature monitoring.

The sensor is supplied with a three meter attached cable and can be connected to a hazard monitoring system, such as 4B’s T500 Hotbus Elite, Watchdog Super Elite, or T400 Elite or to a PLC. The connections are not polarity sensitive therefore special connection requirements are eliminated, and the cable can be extended in the field.

- Screw in positive mount installation

- Grease zerk for bearing lubrication

- WDB8 - 1/4” BSPT with cable entry (stainless steel body)

- WDB2 - 1/8” NPT with conduit entry (stainless steel body)

- WDB1 (Obsolete, use WDB8) - 1/8” NPT with cable entry (brass body)

- NTC version - continuous temperature

- Pt100 version - platinum RTD - continuous temperature

- PTC version - trip points from 50°C to 90°C - step response

- For use with T400, T400 Elite, T500 Elite, Watchdog Super Elite control modules or PLCs

Specifications

| | Part Number | Description | Thermistor Type | Thread | ATEX Zone | IECEx |

| # | ||||||

| WDB810V3AI | Continuous Temperature Monitoring | NTC | 1/4” BSPT | 20 | yes | |

| WDB819V3AI | Continuous Temperature Monitoring | PT100 | 1/4” BSPT | 20 | yes | |

| WDB812V3AI | 60°C Trip Point | PTC | 1/4” BSPT | 20 | yes | |

| WDB813V3AI | 70°C Trip Point | PTC | 1/4” BSPT | 20 | yes | |

| WDB814V3AI | 80°C Trip Point | PTC | 1/4” BSPT | 20 | yes | |

| WDB815V3AI | 90°C Trip Point | PTC | 1/4” BSPT | 20 | yes |

| . | ||||||

| Part Number | Description | Thermistor Type | Thread | ATEX Zone | IECEx | CSA |

| WDB20V3CAI | Continuous Temperature Monitoring | NTC | 1/8” NPT | 20 | yes | Class II Div. 1 |

| WDB29V3CAI | Continuous Temperature Monitoring | PT100 | 1/8” NPT | 20 | yes | Class II Div. 1 |

| WDB22V3CAI | 60°C Trip Point | PTC | 1/8” NPT | 20 | yes | Class II Div. 1 |

| WDB23V3CAI | 70°C Trip Point | PTC | 1/8” NPT | 20 | yes | Class II Div. 1 |

| WDB24V3CAI | 80°C Trip Point | PTC | 1/8” NPT | 20 | yes | Class II Div. 1 |

| WDB25V3CAI | 90°C Trip Point | PTC | 1/8” NPT | 20 | yes | Class II Div. 1 |

| | Part Number | Description | Thermistor Type | Thread | ATEX Zone | IECEx |

| # | ||||||

| WDB10V3AI | Continuous Temperature Monitoring | NTC | 1/8” NPT | 20 | yes | |

| WDB19V3AI | Continuous Temperature Monitoring | PT100 | 1/8” NPT | 20 | yes | |

| WDB12V3AI | 60°C Trip Point | PTC | 1/8” NPT | 20 | yes | |

| WDB13V3AI | 70°C Trip Point | PTC | 1/8” NPT | 20 | yes | |

| WDB14V3AI | 80°C Trip Point | PTC | 1/8” NPT | 20 | yes | |

| WDB15V3AI | 90°C Trip Point | PTC | 1/8” NPT | 20 | yes |

* The WDB1 is no longer stocked and available on request only. We recommend the WDB8 as a replacement sensor.

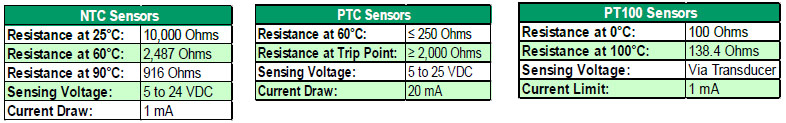

TECHNICAL SPECIFICATIONS

WDB8 Series Bearing Temperature Sensors

Note: WDB8 sensors have stainless steel bodies and do not have conduit entries.

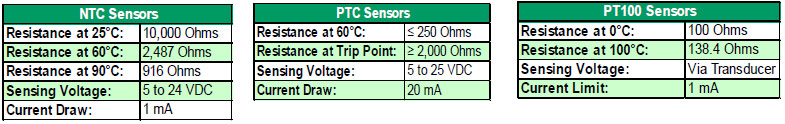

TECHNICAL SPECIFICATIONS

WDB1 and WDB2 Series Bearing Temperature Sensors

NOTE:

WDB Series 1 sensors have brass bodies and do not have conduit entries.

WDB Series 2 sensors are stainless steel bodies with 1/2” NPT conduit entries and are CSA / NRTL Class II Div.1 / ATEX and IECEx Zone 20 approved.

Downloads

Monitors

Watchdog™ Super Elite (WDC4)

The Watchdog Super Elite (WDC4) is easy to install and simple to set-up. The system processes signals from sensors for belt misalignment, belt speed & slip, continuous bearing temperature, pulley misalignment and plug conditions for bucket elevators or belt conveyors. When an alarm is detected it will sound an alarm and provide shutdown control of the elevator/conveyor and feeding system.

A 3.5” LCD screen displays the entire system status at a glance. Password protected controller settings can be set up either directly on the LCD screen, or by a PC application and transferred to the WDC4 via an SD card.

The Watchdog Super Elite can be connected directly to a PLC using the Modbus TCP/IP protocol, or integrated into HazardMon.com®. This secure cloud based solution provides live system status, graphs and historical data that is viewable on any web-enabled device (smart phone, tablet, desktop PC).

T500 Elite Hotbus™

The T500 Elite Hotbus™ is a serial communications system designed to monitor up to 256 sensors for combined belt alignment, belt speed, continuous bearing temperature, pulley alignment, level indication (bin / silo) and plug conditions on bucket elevators and conveyors. With automatic machine shutdown capability and PLC / PC compatibility, this advanced microprocessor based system offers low cost installation, versatility and easy system expansion. Logging and trending software is also available for historic data analysis and preventative or predictive machine maintenance.

HazardMon.com® is a secure cloud based hazard monitoring solution providing status notifications and data logging for bucket elevators and conveyors. Live system status, graphs and historical data can be viewed on any web-enabled device (smartphone, tablet PC, desktop or laptop computer). Emails can be sent to notify users whenever a change in the system's health is detected. An automated maintenance feature allows site operators to verify that all sensors on the system are operational and working correctly.

T400 Elite (PTC Version)

Low cost alarm/indicator controller for use with PTC temperature sensors.

The T400 ELITE is a microprocessor controlled unit which works in conjunction with PTC temperature sensors to monitor up to 48 bearings and can cause alarm and shutdown of the machine when alarm conditions are detected. The control unit is housed in a self contained wall mounting enclosure. A test push button on the lid of the control unit provides for full system verification. Alarm and status LEDs provide quick location of the alarm condition, and voltage free relay contacts provide separate alarm and shutdown control. An alarm mute push button is provided on the lid of the control unit and additional connections are provided for an external alarm mute functionality.

T400N Elite

Unique low cost alarm/indicator panel for use with any 4B NTC-type temperature sensors. ADB810, WDB70, and WDB810 series sensors are recommended.

The T400N ELITE is able to accept signals from up to 8 NTC sensors (zones), which are separated into two groups of 4 zones. Each group of sensors is able to cause alarm and shutdown of individual machine when hazardous conditions are detected. There is a total of 2 Alarm and 2 Stop relays. The control unit is housed in a self contained wall mounting enclosure. A test push button on the lid of the control unit provides for full system verification. Alarm and status LEDs provide means of quick location of the alarm condition, and voltage free relay contacts provide separate alarm and shutdown control. An alarm mute push button is provided on the lid of the control unit and additional connections are provided for an external alarm mute functionality. A rotary switch is used to select the temperature alarm value.

IE-Node

The Industrial Ethernet Node (IE-NODE) is a remote monitoring interface designed to provide sensor data to PLC’s or other automation and control systems.

Both units can be expanded to 16 sensor inputs with the installation of optional expansion boards.

The IE-NODE operates by reading its sensor inputs and sending processed data when requested by another system (e.g. PLC). The units are equipped with an RJ45 Ethernet socket and supports PROFINET, EtherNet/IP and Modbus TCP/IP protocols for easy integration with Siemens, Allen-Bradley Rockwell, Modicon and other PLC’s or automation devices.

The IE-NODE’s network configurator software provides a visual view of all devices on the network. It allows for easy identification of each unit on the network and allows for network settings to be changed as needed.

Design Services

Hazard Monitoring Design Service

Hazard Monitoring Design Service

Preventative maintenance can help reduce the risk of equipment failure and consequent downtimes. When it comes to monitoring your bucket elevators and belt conveyors, 4B can recommend you the ideal combination of sensors and monitoring systems to suit your requirements and budget.

4B provides an extensive range of their own ATEX / IECEx / CSA approved hazard monitoring systems, misalignment switches and bearing temperature monitors and level controls. We can offer you anything from a replacement sensor to a fully integrated hazard monitoring system which can be operated either as a stand-alone system or connected to your PLC.

And if you do not want to install hazard monitoring sensors on every piece of equipment in your plant straightaway, we can offer you a scalable solution starting with carefully chosen equipment and systems that can be expanded at a later date to encompass other machines in the plant.

We can also offer you an installation service, and we do provide a competent after-sales technical service to help you overcome any technical problems with your monitoring equipment.

To get a recommendation from our engineers, please fill in the electronics questionnaire below. Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.

Preventative maintenance can help reduce the risk of equipment failure and consequent downtimes. When it comes to monitoring your bucket elevators and belt conveyors, 4B can recommend you the ideal combination of sensors and monitoring systems to suit your requirements and budget.

4B provides an extensive range of their own ATEX / IECEx / CSA approved hazard monitoring systems, misalignment switches and bearing temperature monitors and level controls. We can offer you anything from a replacement sensor to a fully integrated hazard monitoring system which can be operated either as a stand-alone system or connected to your PLC.

And if you do not want to install hazard monitoring sensors on every piece of equipment in your plant straightaway, we can offer you a scalable solution starting with carefully chosen equipment and systems that can be expanded at a later date to encompass other machines in the plant.

We can also offer you an installation service, and we do provide a competent after-sales technical service to help you overcome any technical problems with your monitoring equipment.

To get a recommendation from our engineers, please fill in the electronics questionnaire below. Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.