The Roto-Safe rotary paddle switch is designed to detect high and low levels of bulk granular solids in bins, tanks, silos, and as blockage detectors in spouts where failsafe detection is required, or for dust hazard areas.

The detection of material is achieved by a rotating paddle. If material impedes the rotation of the paddle, the motor topples of its axis and triggers a contact. The power supply to the motor is cut and the contact signals that a critical level has been reached, which will cause the motor for any inlet or outlet to close down or start up. When the level of the material reaches normal levels again, the motor returns to its initial position and restarts. In the case of a power failure, the Roto-Safe has a fail safe relay that will signal the control room or sound an audible alarm indicating that the unit is not working. Through the control circuit, this alarm can stop any motor filling or emptying the silo. The Roto-Safe also has a built in rotation detection circuit. The output operates from 0 to 20 seconds after the motor has stalled. This feature can be tested by using the magnetic test feature on the outside of the case.

- High and Low Level Indication

- Dust Hazard Approved

- Internal Sensitivity Adjustment

- Adjustable Timer

- Power Failure Alarm

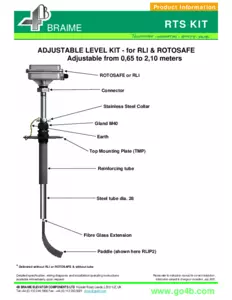

- 14 Foot Vertical Extensions (Maximum)