4B Braime Components is an industry leader in developing high quality, innovative, and dependable material handling components for the agricultural and industrial sectors.

PRODUCTS

Featured Products

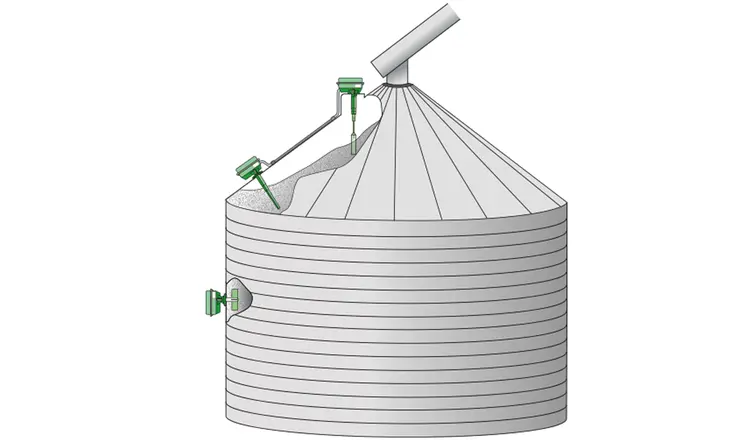

The RG Series of rotary level sensors is suitable for a wide range of bulk granular materials

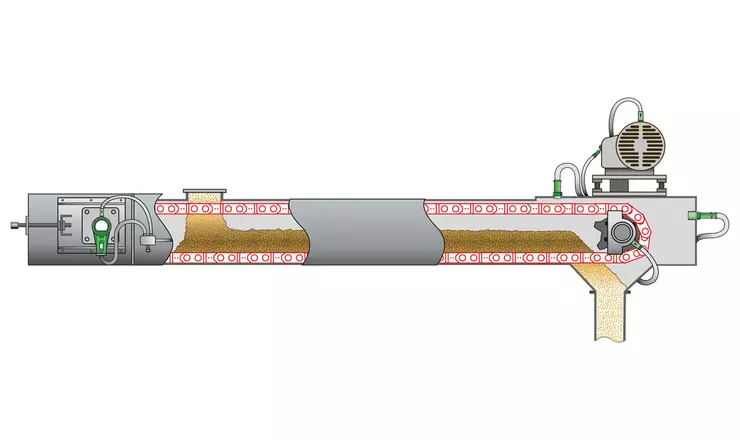

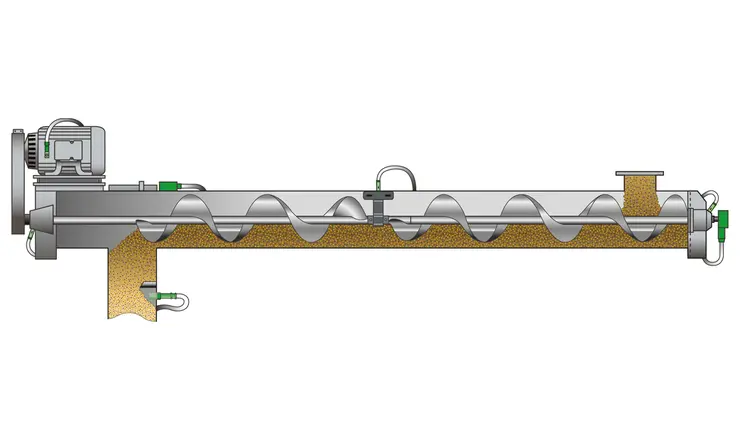

Combined belt speed (slip), belt alignment, continuous bearing temperature, pulley alignment and plug condition monitor for bucket elevators and conveyors.

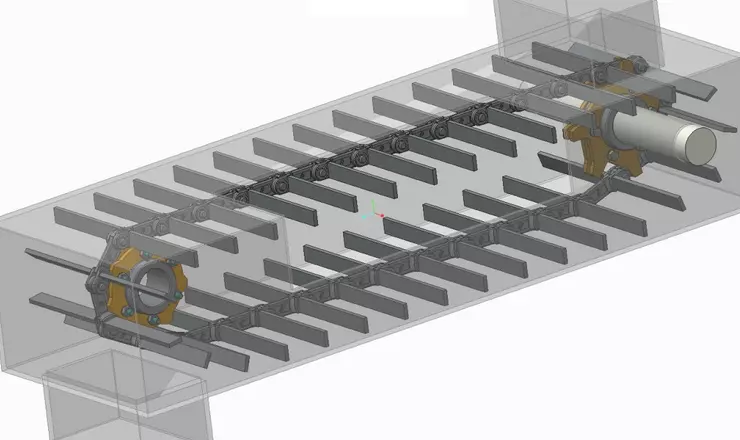

A new assembly system for forged chains- using bolt-on flights instead of welding.

The Encoder-Flex 1024 is a rotary shaft encoder that monitors slide gate position, shaft position

VIBMIL is a vibration sensor designed for continuous monitoring of vibration levels in industrial

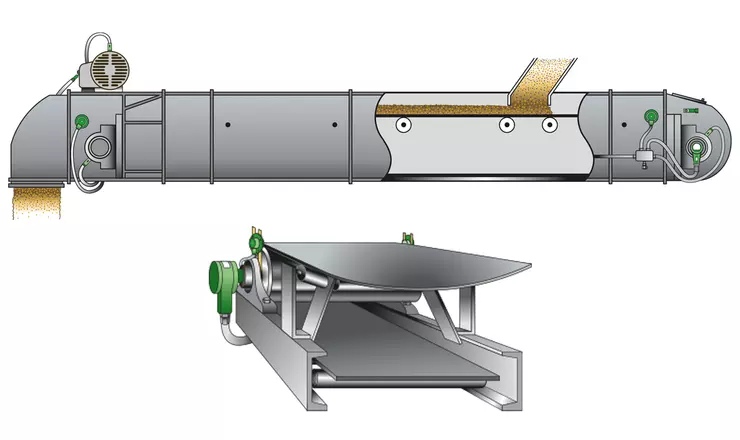

From elevator buckets to forged conveyor chain and level monitors to hazard monitors, 4B is a company you can rely on for the equipment you need.