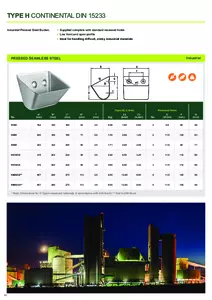

Tłoczony czerpak przemysłowy.

- Wyposażony w standardowe otwory

- Niski przód oraz otwarty profil

- Idealny do przenoszenia lepkich metariałów przemysłowych

Specifications

| H-TYPE | A | B | C | D* | T | Weight | Capacity | Capacity | Holes | E | F | G | |

| Continental bucket | (mm) | (mm) | (mm) | (mm) | (mm) | (kg) | Z2 (total) | Z3 (water) | No. | (dia mm) | (mm) | (mm) | |

| H160 | 162 | 140 | 160 | 63 | 2 | 0.98 | 1.8 | 0.8 | 2 | 9.5 | 80 | 56 | |

| H200 | 200 | 160 | 180 | 71 | 2 | 1.3 | 2.84 | 1.29 | 2 | 11.5 | 125 | 63 | |

| H250 | 253 | 182 | 200 | 80 | 2 | 1.71 | 4.45 | 2.06 | 3 | 11.5 | 80 | 71 | |

| H315/2.0 | 315 | 202 | 224 | 90 | 2 | 2.4 | 6.5 | 3.2 | 3 | 11.5 | 112 | 80 | |

| H315/3.0 | 315 | 202 | 224 | 90 | 2 | 3.6 | 6.5 | 3.2 | 3 | 11.5 | 112 | 80 | |

| H400/2.0** | 407 | 240 | 275 | 113 | 2 | 4 | 13.4 | 6.5 | 4 | 11.5 | 100 | 90 | |

| H400/3.0** | 407 | 240 | 275 | 113 | 2 | 6 | 13.4 | 6.5 | 4 | 11.5 | 100 | 90 |

* Note: Dimensions for H Types measured internally in accordance with DIN norm.

** Not to DIN norm.

Downloads

FAQ's

FAQ - Elevator Buckets

Czym jest czerpak do elewatora WYSOKIEJ WYDAJNOŚCI?

Czerpaki do elewatorów WYSOKIEJ WYDAJNOŚCI posiadają wszystkie pięć z poniższych atrybutów: gładką wewnętrzną powierzchnię czołową bez „przerw”, ściany boczne bez skrzydełek, bliskie pionowe umieszczenie na taśmie elewatora, zwężające się dno oraz możliwość składania do transportu i przechowywania. Aby uzyskać więcej informacji, prosimy KLIKNĄĆ TUTAJ

Dlaczego warto używać niskoprofilowych czerpaków do elewatorów?

Niskoprofilowe czerpaki do elewatorów zostały zaprojektowane w celu uzyskania jak najmniejszych odstępów pionowych na taśmie elewatora, optymalizując w ten sposób system pod kątem potencjalnie najwyższej wydajności. Niektóre rodzaje czerpaków do elewatorów wymagają modyfikacji, a inne są niskoprofilowe standardowo. W niskoprofilowych czerpakach mokry lub ciągnący się materiał wejściowy jest na ogół trudny w załadunku i rozładunku. Ze względu na generowaną dodatkową pojemność i masę dodatkowych czerpaków i materiału, może być konieczne zwiększenie wskaźnika PIW pasa, średnicy wału koła pasowego i mocy silnika. Prosimy o kontakt z działem technicznym 4B w celu ustalenia najlepszego sposobu uzyskania jak największej wydajności nogi elewatora.

W jakim celu dodaje się otwory wentylacyjne na dnie czerpaka elewatora?

Podczas podnoszenia materiałów puszystych lub sypkich otwory wentylacyjne w dnie czerpaka elewatora pozwalają na jego bardziej wydajne napełnianie i opróżnianie. Materiał wchodzący do kubła napotyka poduszkę powietrza spoczywającą na dnie. Otwory wentylacyjne zapewniają drogę ucieczki poduszki powietrza, dzięki czemu wprowadzany materiał nie odbija się od czerpaka i nie spada w dół po obudowie nogi elewatora. Po rozładowaniu, otwory wentylacyjne pozwalają na ponowne wprowadzenie powietrza do czerpaka w miejscach wyjścia materiału, uwalniając podciśnienie utrzymujące się zbyt długo w czerpaku, powodując spadanie materiału.

Czy czerpaki elewatora typu CC można stosować zamiennie z czerpakami elewatora Starco?

Czerpaki elewatora Starco mają specjalną, płytką geometrię i są przeznaczone do umieszczania bardzo blisko siebie na taśmie elewatora. Dlatego przed wymianą czerpaków Starco na czerpaki innej marki lub konstrukcji należy skontaktować się z działem inżynieryjnym 4B.

Śruby elewatora o jakiej grubości należy użyć?

Podczas montażu czerpaków na taśmie elewatora należy użyć poniższego prostego wzoru:

(grubość taśmy + grubość tylnej części czerpaka + grubość podkładki + grubość nakrętki + 1/4 cala)

Czym jest czerpak łyżkowy?

Niektóre materiały mogą powodować powstawanie twardej skorupy wzdłuż bocznej ściany stopy elewatora, a osadzające się z czasem pyły mogą stać się twarde jak skała. Oba te zjawiska mogą powodować przedwczesne zużycie czerpaka elewatora. Czerpaki łyżkowe mają większą szerokość i dalszy zasięg niż standardowe czerpaki, dzięki czemu „przekopują się” przez stwardniały materiał lub rozbijają go, zapobiegając dodatkowemu zużyciu standardowych czerpaków. Czerpaki łyżkowe są tradycyjnie wykonane ze stali, jednak w zależności od zastosowania możliwe jest również użycie czerpaków nylonowych.

Ile czerpaków łyżkowych potrzebuję?

W przypadku większości zastosowań na każde dziewięć standardowych czerpaków należy użyć jednego czerpaka łyżkowego.

Czy mogę używać czerpaków łyżkowych na łączeniu zakładkowym?

Łączenie zakładkowe podwaja grubość taśmy, dlatego zasięg czerpaka zwiększy się. Zwykle nie stanowi to problemu, ale jeśli tak się stanie, można użyć czerpaków krótszych o jeden cal lub skrócić końcówkę każdego czerpaka o pół cala w miejscu łączenia.

Ile dodatkowej taśmy należy użyć w przypadku łączenia zakładkowego?

Długość łączenia powinna wynosić trzykrotność szerokości paska.

Jak często należy wymieniać okładzinę koła pasowego głowicy?

Okładzinę należy wymieniać przy każdej wymianie pasa elewatora.

Design Services

Usługi projektowania podnośników kubełkowych

Usługi projektowania podnośników kubełkowych

W firmie 4B zaprojektowaliśmy setki podnośników kubełkowych dla różnorodnych gałęzi przemysłu, w tym dla zastosowań do transportu pasz dla zwierząt, przeładunku ziarna, mielenia mąki, produkcji słodu, browarnictwa, a także dla przemysłu cementowego, węglowego i innych gałęzi przemysłu ciężkiego.

Zapraszamy do skorzystania z bezpłatnego i gwarantowanego na całym świecie wsparcia technicznego ze strony zespołu inżynierów 4B specjalizujących się w projektowaniu i obliczeniach dotyczących podnośników kubełkowych. Bazując na najważniejszych danych technicznych, nasi inżynierowie mogą udzielić szczegółowych wskazówek technicznych dotyczących optymalnego podnośnika kubełkowego o idealnej wydajności i charakterystyce wyładunku. Możemy zaprojektować nowy podnośnik kubełkowy lub pomóc w zwiększeniu wydajności istniejących linii transportowych.

Aby uzyskać bezpłatną kalkulację dotyczącą podnośnika kubełkowego

Prosimy o jak najdokładniejsze wypełnienie poniższego formularza, abyśmy mogli jak najlepiej odpowiedzieć na Państwa zapytanie.

W firmie 4B zaprojektowaliśmy setki podnośników kubełkowych dla różnorodnych gałęzi przemysłu, w tym dla zastosowań do transportu pasz dla zwierząt, przeładunku ziarna, mielenia mąki, produkcji słodu, browarnictwa, a także dla przemysłu cementowego, węglowego i innych gałęzi przemysłu ciężkiego.

Zapraszamy do skorzystania z bezpłatnego i gwarantowanego na całym świecie wsparcia technicznego ze strony zespołu inżynierów 4B specjalizujących się w projektowaniu i obliczeniach dotyczących podnośników kubełkowych. Bazując na najważniejszych danych technicznych, nasi inżynierowie mogą udzielić szczegółowych wskazówek technicznych dotyczących optymalnego podnośnika kubełkowego o idealnej wydajności i charakterystyce wyładunku. Możemy zaprojektować nowy podnośnik kubełkowy lub pomóc w zwiększeniu wydajności istniejących linii transportowych.

Aby uzyskać bezpłatną kalkulację dotyczącą podnośnika kubełkowego

Prosimy o jak najdokładniejsze wypełnienie poniższego formularza, abyśmy mogli jak najlepiej odpowiedzieć na Państwa zapytanie.