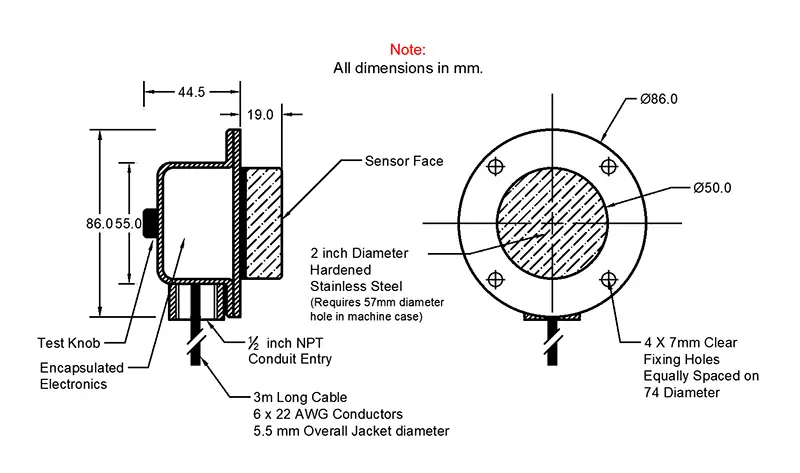

Der TouchSwitch ist ein mechanischer Drucksensor ohne bewegliche Teile. Er fungiert als Schieflaufwächter bei Förderern und Elevatoren. Er detektiert den Seitendruck durch Gurt- oder Bandkanten und aktiviert ein voltfreies Relais, durch das ein Alarm oder Maschinenstillstand ausgelöst wird.

Die Sensoren werden paarweise, d. h. jeweils ein Sensor pro Seite am Fördersystem, installiert. Der Sensor kann direkt an ein SPS-System angeschlossen werden oder für größtmögliche Sicherheit an ein zentrales unabhängiges Überwachungssystem, wie 4B´s T500 Hotbus, IE-Node oder Watchdog Elite.

- Druck-Schieflaufwächter für Band- und Gurtförderer

- Überwacht Schieflauf bei Elevatorgurten und an Transport- und Förderbändern

- Verschleissfeste, kontaktlose Edelstahlkonstruktion

- Funktionsprüfung per Knopfdruck

- Kein Reib-Block, d.h. kein Hitzeaufbau erforderlich

- Kompatibel zu A400 Elite, B400 Elite, T500 Elite, IE-Node und Watchdog Elite

Transportbandförderer

Becherelevator

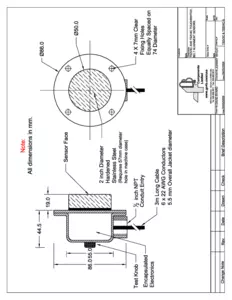

Specifications

| TS2V34AI | TS2V3CAI | TS2V4CAI | |||

| Supply Voltage | 12-24Vdc | 12Vdc | 24Vdc | ||

| Supply Current | 21mA | 60mA | 60mA | ||

| Type | Conduit Entry | Conduit Entry | Conduit Entry | ||

| ATEX/IECEx | Zone 20 | Zone 21 | Zone 21 | ||

| CSA | Not Approved | Class II Div1 | Class II Div1 |

Downloads

Accessories

Lochsäge für Touchswitch™ Gurt-Schieflaufsensor

Empfohlenes Werkzeug für den Einbau des Touchswitch™ Sensors

- Optimale Leistung und Haltbarkeit dank 2-1/4” Hartmetallzähnen

- Pilotbohrer aus Kobaltstahl mit Splitpunkt Spitze verhindert Verrutschen

- Eingebauter Anschlag verhindert ein Überschreiten der Bohrtiefe

- Auswurffeder erleichtert Entnahme des Bohrmaterials

Touchswitch™ Rubber Collar, food grade

This rubber collar is designed for the food industry and is manufactured from food grade material. It is used to properly seal the hole created for the Touchswitch and to protect the sides of the sensor from debris build-up

Monitors

Watchdog™ Super Elite (WDC4)

Der Watchdog Super Elite (WDC4) lässt sich einfach einbauen und einrichten. Das System verarbeitet Signale der verschiedenen Sensorsysteme zur Anzeige von Gurtschieflauf, Gurtgeschwindigkeit und -schlupf, Lagertemperatur, Versatz der Riemenscheibe und Verstopfungen an Förderbändern. Wenn ein ungewöhnlicher Zustand erkannt wird, ertönt ein Alarmsignal und die Abschaltsteuerung für das Becherwerk/Förderband und den Beschicker wird aktiviert.

Auf dem 3,5“ LCD Monitor ist der gesamte Systemstatus auf einen Blick zu erkennen. Die über ein Password geschützten Einstellungen der Steuereinheit lassen sich entweder direkt auf dem LCD Monitor oder über eine PC Anwendung einrichten und auf den WDC4 über eine SD-Karte übertragen.

Der Watchdog Super Elite kann direkt mit einem SPS über das Modbus TCO/IP Protokoll verbunden oder in ein HazardMon.com® integriert werden. Diese sichere, cloudbasierte Lösung ermöglicht es, den Status, Grafiken und historische Daten in Echtzeit über webfähige Geräte (Smartphone, Tablet, Desktop PC) abzurufen.

IE-Node

Die Industrial Ethernet Node (IE-NODE) ist eine Sensorschnittstelle für die Fernüberwachung, über die Sensordaten mit den SPS oder anderen Automatisierungs- und Steuersystemen geteilt werden.

Durch den Einbau zusätzlicher Erweiterungsplatinen lassen sich beide Versionen auf 16 Sensoreingänge ausbauen.

Die IE-Node liest die Sensorsignale an ihren Eingängen und sendet die verarbeiteten Daten, wenn diese von einem anderen System abgerufen werden (z.B. SPS). Die Geräte sind mit einer Ethernet-Buchse RJ45 ausgestattet und unterstützen PROFINET, EthernNet/IP und Modbus TCP/IP Protokolle, die eine einfache Einbindung in Siemens, Allen-Bradley Rockwell, Modicon und andere SPS oder Automatisierungssysteme erlauben.

Über die Software für die Netzwerkkonfiguration der IE-NODE werden sämtliche Geräte im Netzwerk optisch dargestellt. Somit lassen sich alle Geräte im Netzwerk identifizieren und die Einstellungen im Netzwerk nach Bedarf anpassen.

T500 Elite Hotbus™

Der T500 Elite – Hotbus™ ist ein serielles Kommunikationssystem, das speziell zur Überwachung von maximal 256 Sensoren (u. a. auf Lagertemperatur und Schieflauf) entwickelt wurde. Dieses moderne mikroprozessorgesteuerte System mit automatischer Stoppfunktion ist SPS/PC-kompatibel und ermöglicht kostengünstige Installation, Vielseitigkeit und einfache Systemerweiterung. Dazu bietet eine Software die Möglichkeit der Datenerfassung, deren Auswertung und Analyse für präventive Planung von Maschinenwartungsintervallen.

HazardMon.com® ist ein sicheres Cloud basiertes Überwachungssystem, das Benachrichtigung und Protokollierung Ihres Fabrikzustands ermöglicht. Echtzeit Systemstatus, Graphen und historische Daten können auf jedem webfähigen Gerät angezeigt werden (Smartphone, Tablet-PC, Desktop oder Notebook). E-Mails können verschickt werden, um den Anwender über Änderungen des Systemzustands zu informieren.

B400 Elite Beltswitch

Der B400 Elite ist eine mikroprozessorgestützte Kontrolleinheit, die mittels kapazitiven oder Druck-Schieflaufsensoren Bandschieflauf an einem oder zwei Elevatoren/ Förderern überwacht. Bei Bandschieflauf löst er Alarm aus und bewirkt ggf. eine automatische Abschaltung.

A400 Elite Trackswitch

Der A400 Elite ist eine mikroprozessorgestützte Kontrolleinheit, die mittels Induktivsensoren den Abstand zu sich bewegenden Metallbechern oder Becherschrauben an bis zu zwei Becherelevatoren feststellen. Bei Bandschieflauf löst er Alarm aus und bewirkt ggf. eine automatische Abschaltung. Die Steuerungseinheit verfügt über ein selbsttragendes Gehäuse. Die bis zu 4 Sensoren werden separat davon an den jeweiligen Elevatorschächten angebracht.

FAQ's

Wie unterscheidet sich der "Touchswitch" Sensor von einem "Rub Block"?

Es gibt zwei typische Methoden zur mechanischen Erkennung von Gurt-Schieflauf, und zwar den „Rub Block“ und den „Touchswitch“.

Der „Rub Block“ besteht aus Messing, mit eingebautem Temperatursensor. Der Sensor gibt einen Alarm, wenn der Messingkopf sich bis zur Grenztemperatur erwärmt. Drei Nachteile existieren bei diesem Sensor. Erstens: Während der Messingkopf sich erwärmt, ist der Gurt bereits über eine längere Zeit schief gelaufen. Zweitens: Der Gurt kann mit dem Messingkopf periodisch in Berührung kommen und dann wieder weg laufen, und verschleißt hierbei den Kopf -ohne überhaupt einen Alarm zu geben; somit bleibt Ihre Anlage schutzlos. Drittens: Es gibt keine einfache Testmöglichkeit für den „Rub Block“. Denn dieser müsste in einem potenziellen Gefahrenbereich erhitzt werden!

Der „Touchswitch“ ist die Lösung für diese drei Probleme. Erstens: Er detektiert die seitliche Kraft des Gurtes bei Berührung und gibt Ihnen unverzüglich einen voltfreien Kontakt durch einen Wechsel des Relaiskontakts. Zweitens: Die Oberfläche des Sensors ist aus gehärtetem rostfreien Stahl, die wesentlich abrieb- und verschleissfester ist als Messing. Zum Abschluss: Jeder Touchswitch hat einen Testknopf und eine LED. Somit können Sie beim Festdrehen des Testknopfs einen Gurt-Schieflauf simulieren, während die LED erlischt gefolgt von einem/r Maschinen-Alarm/-abschaltung. Wenn Sie den Drehknopf wieder lösen, simulieren Sie ein Weglaufen des Gurtes vom Touchswitch und die LED geht wieder an.

Videos

Design Services

Beratung zu Risikoüberwachung & Explosions-Schutz

Beratung zu Risikoüberwachung & Explosions-Schutz

Präventives Ex-Schutz Management führt nachweislich zur Minimierung von Schadensfällen und teuren Ausfallzeiten. Sollten Sie vor der Wahl der Ex-Schutz Ausstattung Ihres Elevators/Förderers stehen, erhalten Sie von 4B bezogen auf Ihr Budget präzise Empfehlungen für die ideale Kombination von Sensoren und Überwachungsgeräten.

4B bietet hierzu eine großes Programm aus eigengefertigten ATEX / IECEx / CSA zertifizierten Komponenten wie Schieflaufwächtern, Lagertemperatursensoren, Füllstandswächtern und Überwachungseinheiten. Wir können Ihnen jegwelche Kombination vom reinen Sensor-Update bis hin zu Projektierung kompletter Netzwerk-Überwachungsanlagen für Stand-alone Betrieb oder als Einbindung in Ihr vorhandenes SPS-System anbieten.

Sollten Sie zuerst schrittweise an dieses Thema herangehen wollen, können wir Ihnen auch dazu eine modular erweiterbare Systemlösungen anbieten, wobei Sie mit einer Basisausstattung beginnen und später ganz nach Ihren Bedürfnissen Ihre Überwachung erweitern können.

Eine weitere 4B Servicequalität zeigt sich in unserem kompetenten technischen After-Sales Service, der Sie auf Anfrage bei eventuellen Problemen beim Betrieb Ihrer Überwachungseinrichtung unterstützt.

Bitte füllen Sie den untenstehenden Fragebogen aus, um ein auf Ihre Bedürfnisse zugeschnittenes Angebot zu erhalten.

..

Präventives Ex-Schutz Management führt nachweislich zur Minimierung von Schadensfällen und teuren Ausfallzeiten. Sollten Sie vor der Wahl der Ex-Schutz Ausstattung Ihres Elevators/Förderers stehen, erhalten Sie von 4B bezogen auf Ihr Budget präzise Empfehlungen für die ideale Kombination von Sensoren und Überwachungsgeräten.

4B bietet hierzu eine großes Programm aus eigengefertigten ATEX / IECEx / CSA zertifizierten Komponenten wie Schieflaufwächtern, Lagertemperatursensoren, Füllstandswächtern und Überwachungseinheiten. Wir können Ihnen jegwelche Kombination vom reinen Sensor-Update bis hin zu Projektierung kompletter Netzwerk-Überwachungsanlagen für Stand-alone Betrieb oder als Einbindung in Ihr vorhandenes SPS-System anbieten.

Sollten Sie zuerst schrittweise an dieses Thema herangehen wollen, können wir Ihnen auch dazu eine modular erweiterbare Systemlösungen anbieten, wobei Sie mit einer Basisausstattung beginnen und später ganz nach Ihren Bedürfnissen Ihre Überwachung erweitern können.

Eine weitere 4B Servicequalität zeigt sich in unserem kompetenten technischen After-Sales Service, der Sie auf Anfrage bei eventuellen Problemen beim Betrieb Ihrer Überwachungseinrichtung unterstützt.

Bitte füllen Sie den untenstehenden Fragebogen aus, um ein auf Ihre Bedürfnisse zugeschnittenes Angebot zu erhalten.

..