4B Braime Components is an industry leader in developing high quality, innovative, and dependable material handling components for the agricultural and industrial sectors.

PRODUCTS

Featured Products

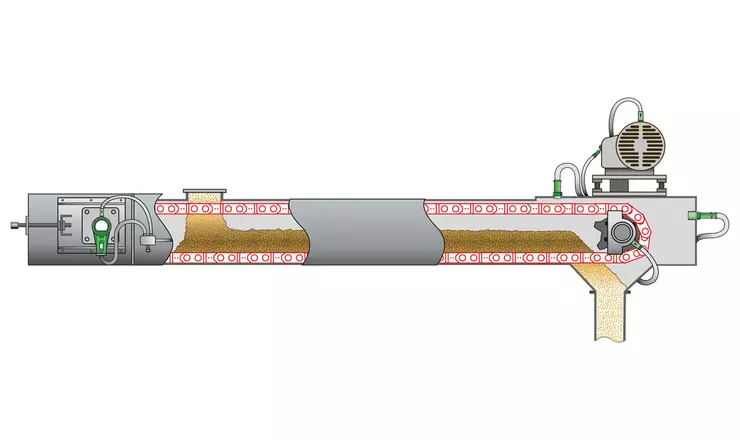

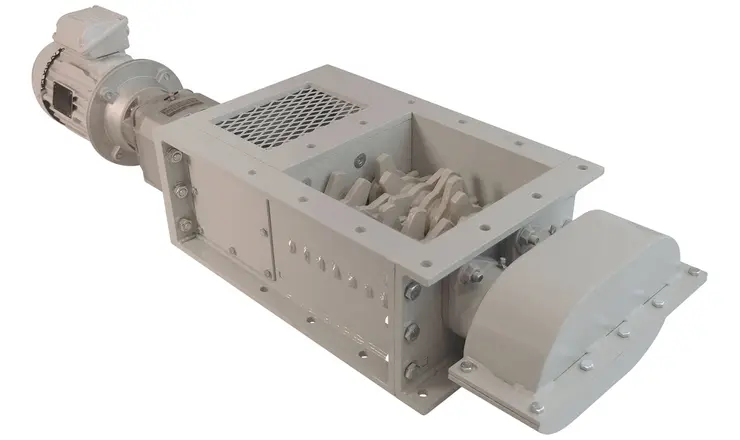

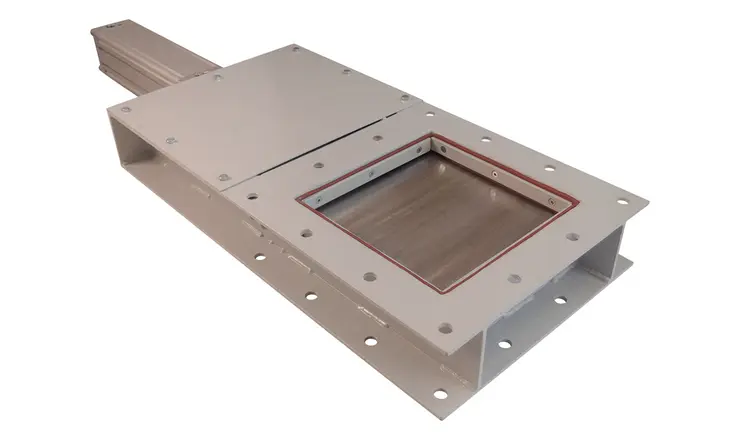

Wear resistant ductile cast iron valve providing a constant volumetric feed rate

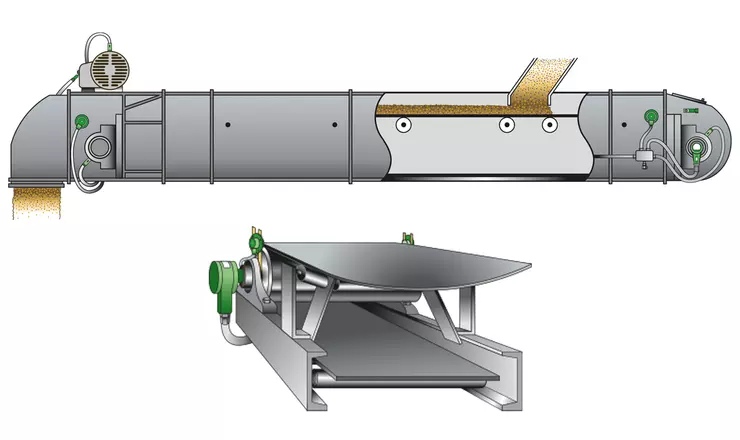

The range of sidewalls comprises many different heights, ranging from 40mm up to 600mm.

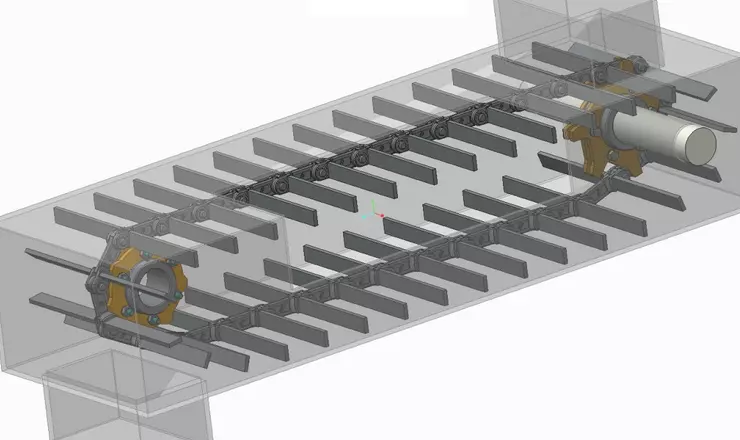

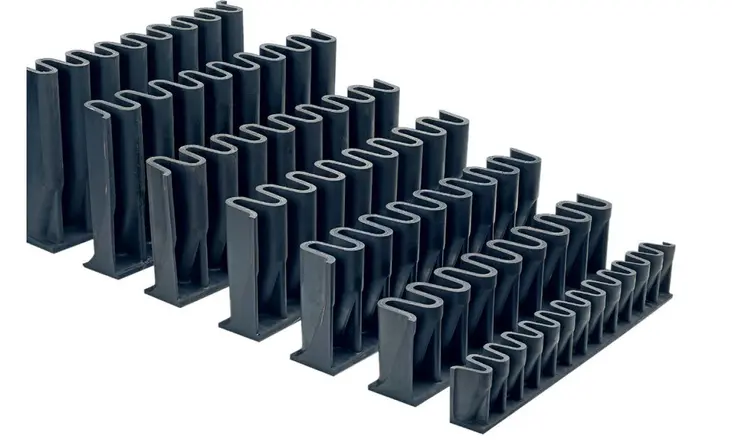

Superior stability and resisting the substantial forces at critical flexing points

From elevator buckets to forged conveyor chain and level monitors to hazard monitors, 4B is a company you can rely on for the equipment you need.