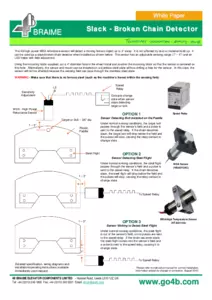

Non-contacting extended range magnetic proximity sensor, not affected by dust or material build up, used to detect moving ferrous material up to 100mm away from the sensor. The WDA sensor can be used on bucket elevators to measure speed and alignment by sensing either the metal elevator buckets, or the ferrous bolts attached to plastic buckets. A more specialized use for the WDA switch is as a broken/slack chain detector on drag chain conveyors, or as a non-contact speed switch for screw conveyors. The sensor is used in conjunction with a PLC or with 4B's Watchdog™ Elite or A400 Elite control units. Two output signals are provided: one signal is a pulse output, representing each bucket detected: the second signal is a continuous output when moving buckets are detected.

- Magnetic Proximity Belt Speed and Belt Alignment Sensor

- Detects Moving Steel Ferrous Targets

- Adjustable Sensing Range of 25 – 75mm

- Not Affected by Material Build Up

- Stainless Steel Construction

- High Temperature Version Available

Bucket Elevator

Chain Conveyor

Specifications

Note: The WDA is Available in Two Models (Standard & High Temp.).

Part numbers & Accessories:

- WDA3V34CAI - WDA Standard Sensor

- HTAS1V34 WDA - High Temperature Sensor

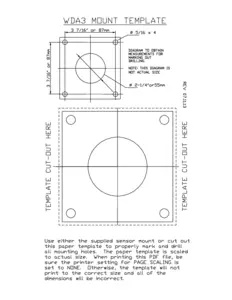

- WDAMB - Sensor Mount (Included with Sensor)

- AS62 - Abrasion Shield

| Parameter | WDA3V34CAI | HTAS1V34 | |

| Supply Voltage | 12-24VDC | 12-24VDC | |

| Supply Current | 65mA | 130mA | |

| Detection Range | 25-75mm | 25-75mm | |

| Detection Rate | 20-2000 Targets/Min | 20-2000 Targets/Minute | |

| Outputs(Max) | 100mA Sink; 50mA Source | 100mA Sink; 1mA Source | |

| ATEX and IECEX | Zone 20 | Not Approved | |

| CSA | Class II Div 1 | Not Approved | |

| Protection | IP66 | IP66 | |

| Temperature Rating | -20°C to +50°C | -29°C to +150°C Continuous | |

| Dimensions | 50mm DIA x 150mm length | 50mm DIA x 150mm length |

Downloads

Monitors

Watchdog™ Super Elite (WDC4)

The Watchdog Super Elite (WDC4) is easy to install and simple to set-up. The system processes signals from sensors for belt misalignment, belt speed & slip, continuous bearing temperature, pulley misalignment and plug conditions for bucket elevators or belt conveyors. When an alarm is detected it will sound an alarm and provide shutdown control of the elevator/conveyor and feeding system.

A 3.5” LCD screen displays the entire system status at a glance. Password protected controller settings can be set up either directly on the LCD screen, or by a PC application and transferred to the WDC4 via an SD card.

The Watchdog Super Elite can be connected directly to a PLC using the Modbus TCP/IP protocol, or integrated into HazardMon.com®. This secure cloud based solution provides live system status, graphs and historical data that is viewable on any web-enabled device (smart phone, tablet, desktop PC).

FAQ's

The WDA sensor will not calibrate, what is the issue?

Make sure that the orange wire is connected correctly, this powers the potentiometer (calibration screw).

Why will the LED on the back of the sensor not turn on?

Check to see that there are no objects stuck to the face of the sensor (washer, bolts, etc.). Due to the magnetic pull on the face of the sensor, objects can stick and interfere with the sensor.

What if the best sensing depth of the WDA sensor?

The WDA sensor can detect ferrous targets from 1 to 3 inches away. Keep in mind the distance of other objects within the sensing area. For example, a belt splice on a bucket elevator may be longer than the intended target and can interfere or hit the WDA sensor.