The new range of deep Super Starco™ elevator buckets is the result of intensive research to achieve the maximum individual bucket capacity, while still maintaining the perfect fill and discharge characteristics of the original standard Starco™ elevator bucket over a wide speed range.

- Provides greater capacity with fewer elevator buckets than the original Starco™ elevator bucket system

- Provides perfect fill & discharge for a wide range of products

- Operates effectively over a wide speed range

- Pressed seamless steel, no welds or joints

- Available in a large number of sizes - now up to 630-215

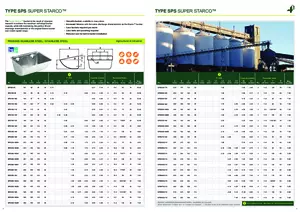

Specifications

| SPS Bucket | A | B | C | D | T/Kg | T/Kg | T/Kg | T/Kg | T/Kg | T/Kg | Cap. (L) | Cap. (L) | Holes | E | F | G | Max. | |

| STEEL | (mm) | (mm) | (mm) | (mm) | 1.0mm | 1.2mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm | Z2 (total) | Z3 (water) | No. | (dia mm) | (mm) | (mm) | Pcs/Mtr | |

| SPS 80-80 | 85 | 80 | 58 | 39 | 0.11 | 0.21 | 0.18 | 2 | 8 | 43 | 16 | 15 | ||||||

| SPS 100-90 | 106 | 89 | 66 | 45 | 0.12 | 0.18 | 0.4 | 0.33 | 0.25 | 2 | 8.5 | 50 | 20 | 14 | ||||

| SPS 100-100 | 105 | 97 | 78 | 46 | 0.18 | 0.42 | 0.29 | 2 | 8.5 | 50 | 25 | 12 | ||||||

| SPS 120-100 | 125 | 105 | 77 | 53 | 0.22 | 0.33 | 0.58 | 0.44 | 2 | 8 | 67 | 25 | 12 | |||||

| SPS 140-110 | 146 | 112 | 91 | 40 | 0.43 | 0.76 | 0.41 | 2 | 8.5 | 70 | 25 | 10.5 | ||||||

| SPS 130-120 | 138 | 120 | 90 | 62 | 0.3 | 0.38 | 0.83 | 0.65 | 2 | 8.5 | 70 | 25 | 10.5 | |||||

| SPS 140-120 | 146 | 120 | 90 | 62 | 0.4 | 0.8 | 0.87 | 0.65 | 2 | 8.5 | 70/86* | 25 | 10.5 | |||||

| SPS 160-140 | 166 | 147 | 112 | 78 | 0.55 | 0.73 | 1.1 | 1.58 | 1.2 | 2 | 8.5 | 100 | 30 | 8.6 | ||||

| SPS 180-140 | 187 | 147 | 112 | 78 | 0.61 | 0.81 | 1.22 | 1.75 | 1.35 | 2 | 8.5 | 100 | 30 | 8.6 | ||||

| SPS 200-150 | 205 | 150 | 112 | 77 | 0.77 | 1.03 | 1.54 | 2 | 1.53 | 2 | 9 | 100/102* | 32 | 8.6 | ||||

| SPS 230-160/A | 233 | 160 | 122 | 85 | 0.86 | 1.15 | 1.72 | 2.72 | 2.05 | 3 | 9 | 70 | 32 | 8 | ||||

| SPS 230-160/B | 233 | 160 | 122 | 85 | 0.86 | 1.15 | 1.72 | 2.72 | 2.05 | 2 | 10.5 | 120 | 32 | 8 | ||||

| SPS 240-160/A | 247 | 165 | 130 | 92 | 1.35 | 2 | 3.03 | 2.37 | 3 | 10.5 | 70/77* | 35 | 7.4 | |||||

| SPS 240-160/B | 247 | 165 | 130 | 92 | 1.35 | 2 | 3.03 | 2.37 | 2 | 10.5 | 140 | 35 | 7.4 | |||||

| SPS 240-160/C | 247 | 165 | 130 | 92 | 1.35 | 2 | 3.03 | 2.37 | 2 | 10.5 | 120 | 35 | 7.4 | |||||

| SPS 260-165 | 262 | 165 | 130 | 92 | 1.38 | 2.1 | 3.28 | 2.55 | 3 | 10.5 | 77/80* | 35 | 7.4 | |||||

| SPS 280-165 | 289 | 167 | 132 | 93 | 1.55 | 2.32 | 3.78 | 2.8 | 3 | 10.5 | 80 | 38 | 7.4 | |||||

| SPS 300-165/A | 308 | 165 | 135 | 94 | 1.65 | 2.08 | 2.5 | 3.88 | 2.9 | 3 | 9 | 100/104* | 36 | 7.2 | ||||

| SPS 300-165/B | 308 | 165 | 135 | 94 | 1.65 | 2.08 | 2.5 | 3.88 | 2.9 | 3 | 11 | 100 | 36 | 7.2 | ||||

| SPS 330-165 | 340 | 165 | 135 | 97 | 1.9 | 2.37 | 2.85 | 4.4 | 3.5 | 3 | 11 | 110/120* | 38 | 7.2 | ||||

| SPS 350-165/A | 360 | 165 | 135 | 94 | 2.12 | 3.2 | 4.5 | 3.65 | 4 | 9 | 90 | 38 | 7.2 | |||||

| SPS 350-165/B | 360 | 165 | 135 | 94 | 2.12 | 3.2 | 4.5 | 3.65 | 3 | 11 | 120 | 38 | 7.2 | |||||

| new | SPS 230-170 | 235 | 170 | 132 | 93 | 1.4 | 3.09 | 2.4 | 2 | 11 | 120 | 35 | 7 | |||||

| SPS 200-180 | 204 | 182 | 140 | 98 | 1.28 | 2.84 | 2.17 | 2 | 11 | 110 | 44 | 7 | ||||||

| SPS 260-180 | 270 | 188 | 140 | 96 | 1.58 | 4.1 | 4.1 | 3.2 | 3 | 11 | 80 | 45 | 7 | |||||

| SPS 280-180 | 290 | 185 | 140 | 97 | 1.7 | 2.55 | 4.4 | 3.3 | 3 | 11 | 80 | 38 | 7 | |||||

| SPS 300-180/A | 308 | 182 | 140 | 95 | 1.8 | 2.7 | 4.5 | 3.5 | 3 | 9 | 100/104* | 36 | 7 | |||||

| SPS 300-180/B | 308 | 182 | 140 | 95 | 1.8 | 2.7 | 4.5 | 3.5 | 3 | 11 | 100 | 36 | 7 | |||||

| SPS 330-180 | 340 | 182 | 140 | 98 | 2 | 5.2 | 4 | 3 | 11 | 110/120* | 38 | 7 | ||||||

| SPS 350-180/A | 362 | 182 | 140 | 98 | 2.1 | 3.15 | 5.4 | 4.2 | 4 | 9 | 90 | 38 | 7 | |||||

| SPS 350-180/B | 362 | 182 | 140 | 98 | 2.1 | 3.15 | 5.4 | 4.2 | 3 | 11 | 120 | 38 | 7 | |||||

| SPS 370-180 | 385 | 195 | 140 | 95 | 2.24 | 2.8 | 6.4 | 4.9 | 4 | 11 | 90 | 38 | 7 | |||||

| SPS 250-215 | 257 | 215 | 162 | 113 | 1.86 | 5.3 | 4.1 | 3 | 11 | 85 | 49 | 5.88 | ||||||

| SPS 280-215 | 294 | 215 | 163 | 114 | 2.18 | 2.86 | 3.08 | 6.04 | 4.7 | 3 | 11 | 80 | 50 | 5.88 | ||||

| SPS 300-215 | 310 | 220 | 163 | 112 | 2.32 | 2.9 | 3.48 | 6.7 | 5.2 | 3 | 11 | 100 | 50 | 5.88 | ||||

| SPS 330-215 | 340 | 215 | 163 | 112 | 2.97 | 3.56 | 7.2 | 5.65 | 3 | 11 | 120 | 50 | 5.88 | |||||

| SPS 350-215 | 362 | 215 | 163 | 112 | 3.23 | 3.87 | 7.6 | 5.86 | 3 | 11 | 120 | 50 | 5.88 | |||||

| SPS 370-215 | 381 | 215 | 163 | 112 | 3.32 | 4 | 8.1 | 6.3 | 4 | 11 | 90 | 50 | 5.88 | |||||

| SPS 440-215 | 450 | 225 | 165 | 113 | 3.92 | 4.68 | 9.83 | 7.44 | 4 | 11 | 110 | 50 | 5.88 | |||||

| SPS 450-215 | 464 | 215 | 163 | 113 | 4 | 4.8 | 9.95 | 7.9 | 5 | 11 | 88/90* | 50 | 5.88 | |||||

| SPS 470-215 | 480 | 225 | 165 | 113 | 4.14 | 4.95 | 10.56 | 8.06 | 4 | 11 | 120 | 50 | 5.88 | |||||

| SPS 500-215 | 515 | 215 | 163 | 113 | 4.28 | 5.14 | 11.25 | 8.8 | 5 | 11 | 100 | 50 | 5.88 | |||||

| new | SPS 630-215 | 630 | 220 | 164 | 113 | 7.4 | 14.29 | 10.92 | 7 | 11 | 90 | 50 | 5.88 |

T = Thickness in mm

Special holes/thicknesses/wearbands - available on request

Wear band size: 3.0mm on 1 or 3 sides on request.

* Slotted holes to fit alternate hole centres

For Stainless Steel, see price list for thickness options !

Downloads

FAQ's

FAQ - Elevator Buckets

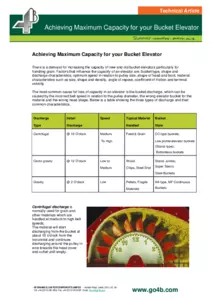

What is a HIGH EFFICIENCY elevator bucket?

HIGH EFFICIENCY elevator buckets incorporate all five of the following characteristics: a smooth interior front face with no "breaks", wing-less side walls, close vertical placement on the elevator belt, a tapered bottom and the ability to nest for shipping and storage. For more details, CLICK HERE

Why use Low Profile elevator buckets?

Low profile elevator buckets are created to achieve the closest vertical spacing possible on the elevator belt, thereby optimizing the system for the greatest potential capacity. Some styles of elevator bucket require modification and others are low profile by standard design. Wet or sluggish inputs do not generally load and discharge well in low profile buckets. Due to the extra capacity that is generated and the weight of the additional buckets and material, belt PIW rating, pulley shaft diameters and motor HP may have to be upgraded. Check with 4B engineering department about the best way to get the most capacity out of your elevator leg.

Why add vent holes to the bottom of an elevator bucket?

When elevating fluffy or powdery materials, vent holes in the bottom of the elevator bucket allow it to fill and discharge more efficiently. As material enters the bucket, it encounters a pillow of air resting in the bottom. Vent holes provide an escape path for this pillow of air, so that the entering material does not bounce out of the bucket and back down the elevator leg casing. Upon discharge, the vent holes allow air to re-enter the bucket at the material exits, releasing any vacuum that might hold it the bucket too long, creating down legging.

Are CC style elevator buckets interchangeable with Starco elevator buckets?

Starco elevator buckets have a special shallow geometry and are intended to be placed extremely close together on the elevator belt. Therefore, you should check with the 4B engineering department before replacing Starco elevator buckets with any other brand or design.

How long of an elevator bolt do I need?

When installing buckets on an elevator belt, use this simple formula:

(belt thickness + bucket back thickness + washer thickness + nut thickness + 1/4 inch)

What is a "digger" bucket?

Some materials can form a hardened crust along the side wall of the elevator boot, and powders sitting over time can become rock hard. Both of these issues can cause premature elevator bucket wear. Digger buckets are designed to have slightly more width and projection than standard buckets, thereby "digging" through or breaking apart the hardened material, helping to prevent added wear to the standard buckets. Digger buckets are traditionally made from steel, however nylon buckets may also be used depending on the application.

How many digger buckets do I need?

For most applications, use one digger bucket for every nine standard buckets.

Can I use buckets on an overlap splice?

An overlap splice doubles the thickness of the belt, so a bucket's projection will increase on the overlap. Usually this will not cause a problem, but if it does, you can use buckets with one inch less projection or cut the tip of each bucket by half an inch on the spliced area.

When using an overlap splice, how much extra belt should I use for the splice?

The length of the splice should be three times the width of the belt.

How often should I replace head pulley lagging?

Lagging should be replaced every time the elevator belt is replaced.

Design Services

Bucket Elevator Design Service

Bucket Elevator Design Service

At 4B, we have designed hundreds of bucket elevators for all industries, including Animal Feed, Grain Handling, Flour Milling, Malting & Brewing through to Cement, Coal and other heavy industries.

Take advantage of 4B's free, guaranteed worldwide technical support service from a team of engineers specialising in the design and calculation of bucket elevators.. Using your key technical data, our engineers can give you a detailed technical recommendation for the ideal bucket elevator with the ideal capacity and discharge characteristics. We can either design your new bucket elevator or we can help you to increase the capacity of your existing bucket elevator.

To get a free bucket elevator calculation

Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.

At 4B, we have designed hundreds of bucket elevators for all industries, including Animal Feed, Grain Handling, Flour Milling, Malting & Brewing through to Cement, Coal and other heavy industries.

Take advantage of 4B's free, guaranteed worldwide technical support service from a team of engineers specialising in the design and calculation of bucket elevators.. Using your key technical data, our engineers can give you a detailed technical recommendation for the ideal bucket elevator with the ideal capacity and discharge characteristics. We can either design your new bucket elevator or we can help you to increase the capacity of your existing bucket elevator.

To get a free bucket elevator calculation

Please fill this form in as accurately as possible to allow us to deal with your enquiry more effectively.