The Auto-Set flush probe is a low profile RF capacitance plug switch level monitor designed for tight fitting applications to detect levels of liquids, powders and free flowing granular solids in conveyors, bucket elevators and surge hoppers.

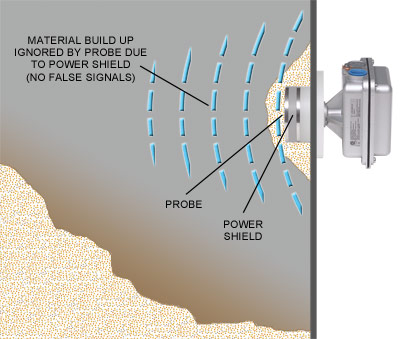

The Auto-Set flush probe incorporates simple push-button calibration with microprocessor enable/disable switch for total protection of stored values. Once the Auto-Set is calibrated for the application it never has to be re-calibrated. Data is stored in non-volatile memory so it is not affected by power loss. A four digit LED display shows set values for uncovered, covered and trip settings, allowing simple set-up and adjustment. A set of voltage-free changeover relay contacts are actuated when the level of the material in the container reaches the probe. The unit incorporates a unique power shield which automatically compensates for material build-up around the probe and on the sides of the container, preventing false indication. The solid state electronics are housed in a weatherproof, flame retardant, glass-reinforced nylon enclosure. The Auto-Set is top or side mountable, and the probe inserts 2.5 to 5cm into a tank or spouting, has no moving parts and is made from 6.3mm 316 stainless steel plate. It can be used with container walls up to 2.5cm thick.

- High and Low Level Indication

- Ideal for Low Profile Applications

- Fail-Safe

- Push Button Calibration

- Digital Display and Internal Timer

- Power Shield Compensates for Material Build Up