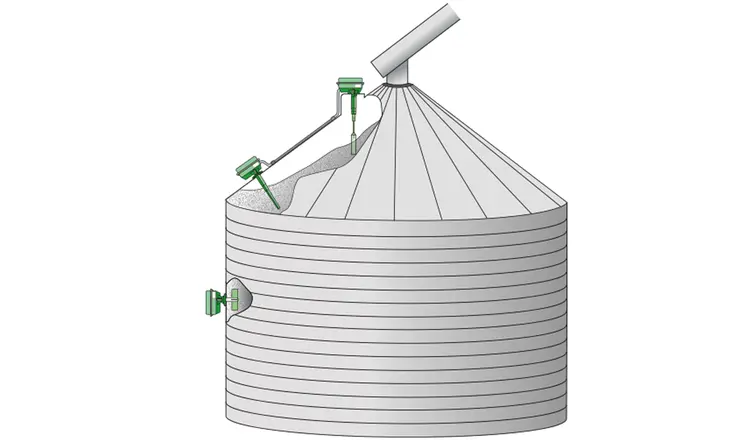

4B Braime Components is an industry leader in developing high quality, innovative, and dependable material handling components for the agricultural and industrial sectors.

The IE-GuardFlex is the central control unit for 4B’s Distributed Hazard Monitoring Solution (DHM